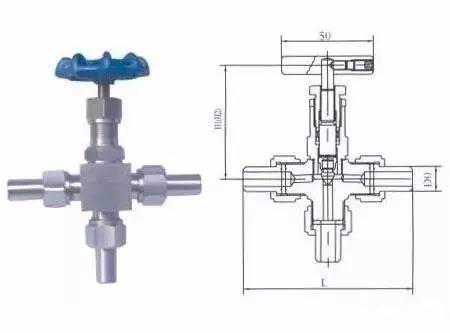

3 Way Stainless Steel Ball Valve

The Application of 3 Way Stainless Steel Ball Valve

The 3 Way Stainless Steel Ball Valve is a versatile solution for fluid control in various industries. Manufactured through the rigorous industrial valve manufacturing process, it ensures durability and reliability. Unlike traditional hvac valve types, it offers multi-directional flow control, ideal for complex piping systems. With brands like Cameron known for quality brass ball valves, and suppliers like SKG Pneumatics Inc, offering precision butterfly valve seats, the 3 Way Stainless Steel Ball Valve is a trusted choice. Its functionality extends to applications where fluid diversion or mixing is required, such as in HVAC systems, industrial processes, or wastewater treatment plants. This valve’s design, similar to that of the Intec Duoball Valve or KGC-BD knife gate valve, ensures efficient operation and minimal maintenance needs, making it a valuable asset in various industrial settings.

Advantages of 3 Way Stainless Steel Ball Valve

- Full Port for unrestricted flow

- Blow-out proof stem

- Live-loaded Pyramidal stem seal design

- Integrated mounting pad for actuators

- Compact assembly

- Complete line of accessories

Specification of 3 Way Stainless Steel Ball Valve

| Working Pressure | Up to 6000 psig (413 bar) |

| Temperature Range | -40 to 248°F (-40 to 120°C) |

| Flow Coefficient | 3.8 to 40 |

| Body Material | CF8M/ 316 stainless steel, alloys 6-Mo, Duplex 2507, Inconel 625, Monel Alloy 400, Incoloy 825, and Hastelloy C276 |

| Seat Materials | PEEK |

| End Connection | BSP / NPT / RF / RTJ / SW / BW |

| Sizes | 1/2 to 12 in.; 15 to 300 mm |

| Configurations | On-off |

| All Types of 3 Way Ball Valve manufacturer | Full Bore Ball ValveOne-Piece Instrumentation Ball ValveMultipurpose Ball ValveThree-Piece Process Instrumentation Ball ValveTrunnion Ball Valve |

| High Pressure 3 Way Ball Valve Pressure Rating (CWP) | 1000 PSI / 69 Bar400 PSI / 27.6 Bar600 PSI / 41.4 Bar |

| 3 Way Flanged Ball Valve Pressure Rating (SWP) | 150 PSI / 10.3 Bar200 PSI / 13.8 Bar |

| 3 Way Actuated Ball Valve Pressure Rating (WWP) | 300 PSI / 20.7 Bar |

| Features | Multiple handle optionsPress leak-detection featureFlanged end connectionsLocking Lever Locking handle or manual gear operatorLaser Welded Threaded end connectionsPress x press female end connectionsReinforced PTFE Seat Rings |

| Conforms to | MSS SP-110MSS SP-145CSA B125.14NSF/ANSI-372API-608 Anti-StaticCC-ES PMG-1558ASME A112.4.14IAPMO/ANSI Z1157NACE MR0175API-607 Fourth Edition Fire Safe |

The Operation Theory of 3 Way Stainless Steel Ball Valve

The operation theory of 3 Way Stainless Steel Ball Valve involves a spherical ball with multiple ports to control flow direction. Unlike traditional globe valve vs ball valve, it provides versatile flow configurations. Similar to the Intec Duoball, it offers efficient fluid control. Used in diverse applications like cooling towers, it’s crucial for cooling tower valves company offerings. Understanding ball valve vs globe valve distinctions aids in selecting the right valve for specific pressure ratings, API standards, and temperature requirements.

The Parameters Table of 3 Way Stainless Steel Ball Valve

| Parameter | Description |

|---|---|

| Material | Stainless Steel |

| Size Range | Various sizes available |

| Pressure Rating | Up to 6000 PSI (Pounds per Square Inch) |

| Temperature Range | -20°F to 400°F (-29°C to 204°C) |

| End Connections | Threaded, Socket Weld, Flanged |

| Design Standards | API, ANSI, ASTM |

| Sealing Material | PTFE (Teflon), RTFE |

| Flow Configuration | 3-way diverter, 3-way mixing, or L-port |

| Actuation | Manual, Pneumatic, Electric |

Relevant Information about 3 Way Stainless Steel Ball Valve

- Rotor: The rotating ball inside the valve that controls the flow direction.

- Stator: The stationary body of the valve that supports and guides the rotor.

- Universal Joint: Not typically present in ball valves.

- Shaft Seal: Prevents leakage along the valve stem, ensuring a tight seal.

- Driving System: Typically manual, using a handle to turn the rotor, or automated with pneumatic or electric actuators.