Carbon Steel Gate Valve

The Application of Carbon Steel Gate Valve

Rotork Carbon Steel Gate Valve, alongside products from ZECO Valve and Cameron, is indispensable in cooling tower applications. Designed to regulate fluid flow, especially in cooling tower valves, these valves endure high temperatures and pressures. Their robust construction ensures durability, allowing easy inspection of valve seats for maintenance. With reliable performance, these valves contribute significantly to the efficient operation of cooling tower systems and other industrial processes.

dsi valve

dsi check valve

cameron butterfly valves

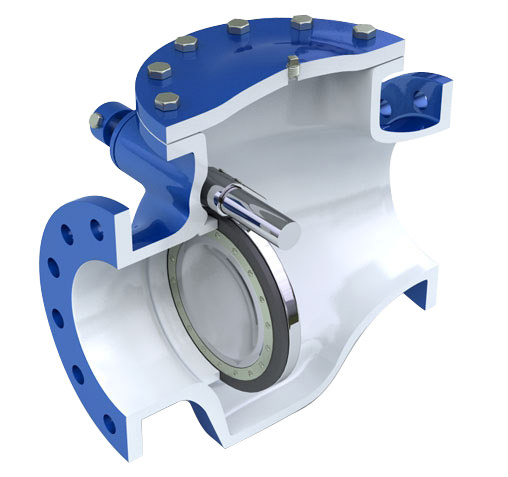

What Is Carbon Steel Gate Valve?

A carbon steel gate valve is a type of valve specifically designed for controlling the flow of fluids in pipelines, particularly in industrial applications where high temperatures and pressures are common. These valves are constructed using carbon steel, a robust and durable material known for its strength and resistance to corrosion. They feature a gate mechanism that can be raised or lowered to either allow or restrict the flow of fluid through the valve. Carbon steel gate valves are widely used in various industries such as oil and gas, petrochemical, power generation, and water treatment, where reliable and efficient flow control is essential.

Features of Carbon Steel Gate Valve

- Material Quality: ZECO’s carbon steel gate valve is made from high-quality ASTM A216 WCB carbon steel, ensuring durability and resistance to corrosion. Its mechanical properties include a strong tensile strength and high yield point, making it suitable for demanding industrial applications.

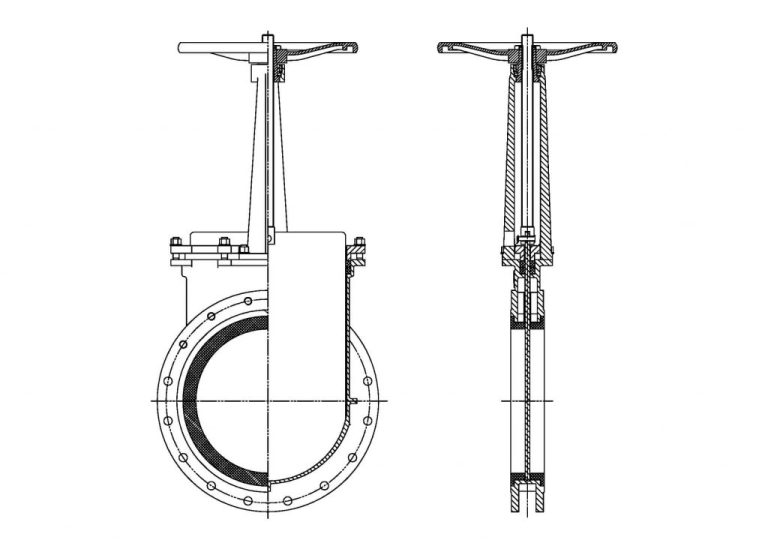

- Thrust Bearing Design: The valve features a thrust bearing design on the stem nut, allowing for smooth and flexible operation during valve opening, reducing the effort required by maintenance personnel.

- Sealed Structure: A sealed structure is incorporated into the upper end of the bonnet, enabling safe replacement of packing during maintenance without risking leakage, ensuring operational safety and minimizing downtime.

- Guided Wedge Design: During the valve’s operation, the wedge remains fixed within the guide rail of the valve body, preventing jamming and ensuring smooth opening and closing motions. This design enhances the valve’s reliability and longevity.

- Seat Face Treatment: The seat face is alloy hard-faced, ground, and lapped to a mirror finish, ensuring tight sealing and preventing seat damage, even under high-pressure conditions.

- Flexible Wedge Options: The valve offers flexible wedge options with low center stem contact, available in various materials such as solid CA15 or hard-faced with alloys like 13Cr, SS 316, Monel, or CF8M, catering to diverse operational requirements.

- Non-Rotating Stem: The valve’s stem features precision Acme threads and a burnished finish, with options for double Acme threads for faster operation and improved performance.

- Accurate Machining: Both the body and bonnet joint are accurately machined, ensuring precise alignment and minimizing the risk of leaks.

- One-Piece Bonnet: For sizes up to NPS 12 (DN 300), the valve features a one-piece bonnet design, simplifying assembly, enhancing alignment, and reducing the number of parts for improved reliability.

- Optional Features: Additional features such as a locking device or stem extension, as well as the option for direct mounting to ISO 5211 standards, provide customization and compatibility with various applications and industry standards.

Advantages of Carbon Steel Gate Valve

- Durability: Carbon steel gate valves are known for their robust construction, making them highly durable and capable of withstanding high-pressure and high-temperature environments commonly found in industrial settings.

- Corrosion Resistance: Carbon steel gate valves exhibit excellent resistance to corrosion, ensuring long-term reliability and minimizing the risk of degradation over time, even in harsh operating conditions.

- Versatility: These valves are suitable for a wide range of applications across industries due to their ability to handle diverse fluids, including water, oil, gas, steam, and more, making them versatile solutions for various industrial processes.

- High Performance: Carbon steel gate valves offer excellent flow control capabilities, allowing for precise regulation of fluid flow rates, pressures, and volumes, thereby optimizing system performance and efficiency.

- Ease of Maintenance: With simple and straightforward maintenance requirements, carbon steel gate valves are easy to inspect, repair, and maintain, reducing downtime and minimizing operational disruptions.

- Cost-Effectiveness: Compared to valves made from other materials, carbon steel gate valves often offer a cost-effective solution without compromising on quality or performance, making them a preferred choice for budget-conscious projects.

- Long Service Life: Thanks to their durable construction and corrosion-resistant properties, carbon steel gate valves typically have a long service life, providing reliable operation and minimal need for replacement or repairs over time.

- Wide Range of Sizes and Pressure Ratings: Carbon steel gate valves are available in a wide range of sizes and pressure ratings, allowing for customization to meet specific project requirements and ensuring compatibility with various piping systems.

- Compliance with Standards: These valves are often designed and manufactured to meet industry standards and specifications, ensuring compliance with regulatory requirements and enhancing safety and reliability in industrial applications.

- Proven Reliability: Carbon steel gate valves have a proven track record of reliability and performance in demanding applications across industries, earning them trust and recognition as essential components in industrial fluid control systems.

The Specifications of Carbon Steel Gate Valve

| Specification | Details |

|---|---|

| Type | Gate Valve |

| Body Material | Carbon Steel |

| Ball Material | N/A |

| Attachment Type | Flanged, Threaded, Welded, etc. |

| Thread Standard | ANSI, DIN, BS, JIS, etc. |

| Thread Size | Various sizes available |

| Safe for Use With | Water, Oil, Gas, Steam, etc. |

| Handle Type | Handwheel, Gear Operated, etc. |

| Handle Material | Carbon Steel, Stainless Steel, etc. |

| Maximum Working Pressure (psi) | Up to specified pressure |

| Maximum Working Pressure (bar) | Up to specified pressure |

| Operating Pressure | Varies depending on application |

The Parameter of Carbon Steel Gate Valve

Material: Made of high-quality carbon steel, ensuring durability and strength.Design: Engineered with precision to meet industry standards for gate valves.Operating Mechanism: Utilizes a rising stem design for easy operation and clear indication of valve position.Sealing: Features a resilient seat and wedge, ensuring tight sealing and preventing leakage.Pressure Rating: Available in various pressure ratings to suit different applications and system requirements.End Connections: Compatible with flanged, threaded, or welded connections for easy installation in diverse piping systems.Size Range: Offered in a wide range of sizes to accommodate different flow rates and pipe diameters.Application: Suitable for various industries including oil and gas, petrochemical, power generation, and water treatment.Optional Features: Can be customized with additional features such as locking devices or stem extensions based on specific needs.

The Operation Theory of Carbon Steel Gate Valve

The operation theory of a Carbon Steel Gate Valve revolves around the movement of its components to control the flow of fluid. The valve’s A217 material ensures robustness and resistance to corrosion. When the valve is in operation, the rising stem mechanism raises or lowers the gate to regulate the flow. This action creates a straight-through path for fluid, unlike the obstructive nature of a butterfly valve vs ball valve. The gate’s movement is precise, providing reliable shut-off and flow control in various industrial applications.

The Parameters Table of Carbon Steel Gate Valve

| Parameter | Description |

|---|---|

| Type | Gate Valve |

| Body Material | Carbon Steel (ASTM A217) |

| Seat Material | Alloy hard-faced |

| Stem Material | Stainless Steel (SS 316) |

| Trim Material | Stainless Steel (SS 316) or Alloy |

| Connection Type | Flanged or Threaded |

| Thread Standard | ANSI/ASME B1.20.1 or equivalent |

| Thread Size | Various sizes available |

| Maximum Working Pressure | Depends on size and class rating |

| Maximum Working Pressure bar | Depends on size and class rating |

| Operating Pressure | As per application requirements |