Types of Butterfly Valves

The Application of Butterfly Valves

Introducing Cameron’s range of Butterfly Valves, including the versatile 4 butterfly valve, renowned Bray Butterfly Valves, and innovative triple offset butterfly valve. Cameron’s butterfly valves offer efficient fluid control across various industries, providing reliable performance and durability. The 4 butterfly valve design ensures smooth operation and tight shut-off, while Bray Butterfly Valves are recognized for their superior sealing capabilities and longevity. Cameron’s triple offset butterfly valve features advanced technology for precise flow control in demanding applications. Whether in water treatment plants, HVAC systems, or oil and gas pipelines, Cameron’s Butterfly Valves deliver unmatched performance and reliability.

cameron butterfly valves

triple offset butterfly valve cameron

What Are The Types Of Butterfly Valves?

- Concentric Butterfly Valve: This type features a simple design with a centrally placed disc, suitable for general-purpose applications.

- Double Offset Butterfly Valve: With an offset stem and disc, this valve offers improved sealing performance and reduced torque requirements.

- Triple Offset Butterfly Valve: Known for their superior sealing capabilities and tight shut-off, these valves feature an eccentrically positioned disc and seat arrangement.

- High-Performance Butterfly Valve: Engineered for high-pressure and high-temperature applications, these valves offer enhanced durability and performance.

- Wafer Butterfly Valve: Designed to fit between flanges in a pipeline, these valves are compact and lightweight, ideal for space-constrained installations.

- Lug Butterfly Valve: Similar to wafer valves, lug butterfly valves have threaded inserts or lugs that allow for easy installation and removal from the pipeline.

- Flanged Butterfly Valve: These valves feature flanged ends for direct connection to pipeline flanges, providing a secure and leak-free connection.

What Is Butterfly Valves?

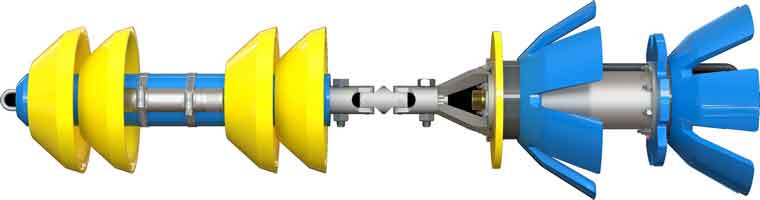

Butterfly Valves are quarter-turn valves used to regulate or isolate the flow of fluids in pipelines. They consist of a circular disc, mounted on a shaft, which rotates to control the flow. When the valve is fully open, the disc aligns with the direction of flow, allowing unrestricted passage. Conversely, when closed, the disc forms a perpendicular barrier, halting the flow. These valves are known for their simplicity, lightweight construction, and quick operation, making them suitable for a wide range of applications across industries such as water treatment, HVAC, and oil and gas.

How to Select the Right Butterfly Valves?

To select the right Butterfly Valves, consider factors like pressure rating, temperature range, fluid compatibility, size, end connection type, and application requirements. Evaluate the operating conditions and consult with valve manufacturers or engineers to ensure compatibility and optimal performance.

Features of Butterfly Valves

- Versatility: Butterfly Valves are versatile, suitable for various applications including water, air, gas, and slurries.

- Quick Operation: These valves offer rapid opening and closing due to their quarter-turn design, enabling efficient flow control.

- Compact Design: With a slim profile and lightweight construction, butterfly valves are space-saving and easy to install.

- Low Pressure Drop: Their streamlined disc design results in minimal obstruction to flow, reducing pressure drop across the valve.

- Cost-Effective: Butterfly valves are often more cost-effective compared to other valve types, making them a preferred choice for many applications.

- Bubble-Tight Shut-off: Advanced sealing technologies ensure bubble-tight shut-off, preventing leakage and ensuring system integrity.

- Maintenance Friendly: Simple construction and fewer components make butterfly valves easy to maintain and service.

- Wide Range of Sizes: Available in a wide range of sizes, from small diameters for residential use to large diameters for industrial applications.

- Corrosion Resistance: Materials such as stainless steel, bronze, and nickel-aluminum bronze offer excellent corrosion resistance, extending valve lifespan in harsh environments.

Advantages and Disadvantages of Butterfly Valves

Advantages:

- Cost-Effectiveness: Butterfly valves are often more affordable than other types of valves, making them a budget-friendly choice.

- Lightweight Construction: Their compact and lightweight design reduces overall system weight and simplifies installation.

- Quick Operation: Butterfly valves offer rapid opening and closing due to their quarter-turn design, enabling efficient flow control.

- Low Pressure Drop: Their streamlined disc design results in minimal obstruction to flow, reducing pressure drop across the valve.

Disadvantages:

- Limited Shutoff Capabilities: Butterfly valves may not provide bubble-tight shut-off in certain applications, leading to potential leakage.

- Throttling Limitations: While suitable for on/off applications, butterfly valves may not offer precise flow control in throttling applications.

- Sensitivity to Cavitation: In high-pressure applications, butterfly valves may be prone to cavitation, which can lead to damage over time.

- Limited Temperature and Pressure Range: Butterfly valves may have limitations in terms of temperature and pressure ratings compared to other valve types.

The Specifications of Butterfly Valves

| Specification | Details |

|---|---|

| Type | Butterfly Valve |

| Ball Material | Stainless Steel, Brass, Bronze, etc. |

| Attachment Type | Lug, Wafer, Flanged, Threaded, Welded, etc. |

| Thread Standard | N/A (for non-threaded types), ANSI, DIN, JIS, etc. |

| Thread Size | N/A (for non-threaded types), 1/4″ to 48″ (for threaded types) |

| Body Material | Cast Iron, Ductile Iron, Carbon Steel, Stainless Steel, etc. |

| Safe for Use With | Water, Air, Gas, Oil, Chemicals, etc. |

| Handle Type | Lever, Gear, Actuator, Handwheel, etc. |

| Handle Material | Stainless Steel, Aluminum, Plastic, etc. |

| Maximum Working Pressure (psi) | Up to 300 psi (20.68 bar) |

| Maximum Working Pressure (bar) | Up to 20.68 bar |

| Operating Pressure | Varies depending on application and valve size |

The Installation Steps for Butterfly Valves

- Preparation: Ensure the work area is clean and free of debris. Gather all necessary tools and equipment for installation.

- Valve Inspection: Check the Butterfly Valve for any visible damage or defects. Verify that all components, including the disc, stem, and seal, are intact and in good condition.

- Valve Positioning: Position the Butterfly Valve in the desired location within the pipeline. Ensure proper alignment with adjoining pipes and fittings.

- Flange Connection: If the valve has flanged ends, align the flanges with the corresponding flange connections on the pipeline. Insert bolts and tighten them evenly to secure the valve in place.

- Welding (if applicable): For welded connections, ensure clean and proper welding techniques are used to join the valve to the pipeline. Follow welding procedures as per industry standards.

- Threaded Connection: If the valve has threaded ends, apply thread sealant or tape to the threads before screwing the valve onto the pipeline. Tighten the valve securely using a suitable wrench.

- Actuator Installation (if applicable): If the Butterfly Valve is equipped with an actuator for automated operation, follow the manufacturer’s instructions for mounting and connecting the actuator to the valve.

- Pressure Testing: Once the valve is installed, conduct a pressure test to ensure there are no leaks or defects. Gradually increase the pressure within the pipeline while monitoring for any signs of leakage.

- Operation Check: Open and close the Butterfly Valve to verify smooth operation and proper sealing. Ensure the valve operates as expected without any sticking or binding.

- Final Inspection: Perform a final visual inspection of the installed valve to confirm that all connections are secure and there are no signs of damage or leaks.

The Operation Theory of Butterfly Valves

- Butterfly Valve Operation: Butterfly Valves operate on the principle of quarter-turn rotation. When the valve handle or actuator is turned, the disc within the valve rotates either perpendicular or parallel to the flow direction. In the fully open position, the disc aligns with the flow, allowing unrestricted passage. Conversely, in the closed position, the disc forms a perpendicular barrier, blocking the flow.

- Types of Butterfly Valves:

- 3 Butterfly Valve: This type of butterfly valve typically refers to a valve with three offset shafts, offering improved sealing performance and reduced wear. It is commonly used in high-pressure and high-temperature applications.

- 6 Butterfly Valve: Similarly, the 6 butterfly valve features six offset shafts, providing even greater sealing capabilities and durability. It is often employed in critical applications where tight shut-off and reliability are paramount.

- Sealing Mechanism: Butterfly Valves employ various sealing mechanisms to ensure tight shut-off and prevent leakage. These mechanisms include resilient seats, such as elastomer or PTFE, which provide a tight seal around the valve disc to prevent fluid from passing through when the valve is closed.

- Flow Control: Butterfly Valves offer precise flow control by adjusting the angle of the disc relative to the flow direction. By partially opening or closing the valve, operators can regulate the flow rate within the pipeline to meet specific process requirements.

- Actuation: Butterfly Valves can be manually operated using a handle or lever, or automated using pneumatic, electric, or hydraulic actuators. Actuators allow for remote operation and precise control of the valve position, enhancing efficiency and safety in industrial processes.

The Parameters Chart of Butterfly Valves

| Parameter | Details |

|---|---|

| Type | Butterfly Valve |

| Body Material | Cast Iron, Ductile Iron, Carbon Steel, Stainless Steel, Aluminum, PVC, etc. |

| Disc Material | Stainless Steel, Ductile Iron, Aluminum Bronze, PVC, etc. |

| Seat Material | EPDM, NBR, PTFE, Viton, etc. |

| Stem Material | Stainless Steel, Carbon Steel, Nickel Alloy, etc. |

| Seal Material | EPDM, NBR, PTFE, Viton, etc. |

| O-ring Material | EPDM, NBR, Viton, Silicon, etc. |

| Body Lining Material | PTFE, Rubber, Polypropylene, etc. |

| Trim Material | Stainless Steel, Brass, Bronze, etc. |

| End Connection Material | Stainless Steel, Carbon Steel, Brass, etc. |