Offset Butterfly Valve

The Application of Offset Butterfly Valve

Introducing Cameron’s innovative solution, the Offset Butterfly Valve. Also known as the double offset butterfly valve or triple offset valve butterfly, it offers superior performance in various applications. With features like the Vanessa triple offset butterfly valve, it provides exceptional sealing capabilities and durability. Ideal for industries such as oil and gas, petrochemical, and water treatment, Cameron’s Offset Butterfly Valve ensures reliable flow control and tight shut-off, even in demanding conditions.

What Are The Types Of Offset Butterfly Valve?

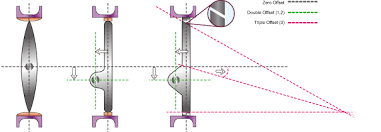

- Double Offset Butterfly Valve: This type of valve features two offsets – one in the shaft and another in the sealing element. It provides improved sealing performance and reduced operating torque compared to a traditional concentric butterfly valve.

- Triple Offset Butterfly Valve: Triple offset butterfly valves feature three offsets – one in the shaft, one in the sealing element, and one in the seat geometry. This design provides exceptional sealing capabilities, making it suitable for high-pressure, high-temperature, and critical applications.

- Metal-Seated Offset Butterfly Valve: Metal-seated offset butterfly valves use metal seats and sealing components, offering excellent resistance to high temperatures, abrasion, and corrosive media. They are ideal for applications requiring tight shut-off and long-term reliability.

- Resilient-Seated Offset Butterfly Valve: Resilient-seated offset butterfly valves utilize elastomeric materials for the seat and sealing elements, providing reliable sealing performance and low torque operation. They are commonly used in water and wastewater treatment, HVAC, and general industrial applications.

- High-Performance Offset Butterfly Valve: High-performance offset butterfly valves are designed to meet stringent performance requirements, such as ANSI Class 1500 or higher pressure ratings, fire-safe certification, and zero leakage performance.

What Is Offset Butterfly Valve?

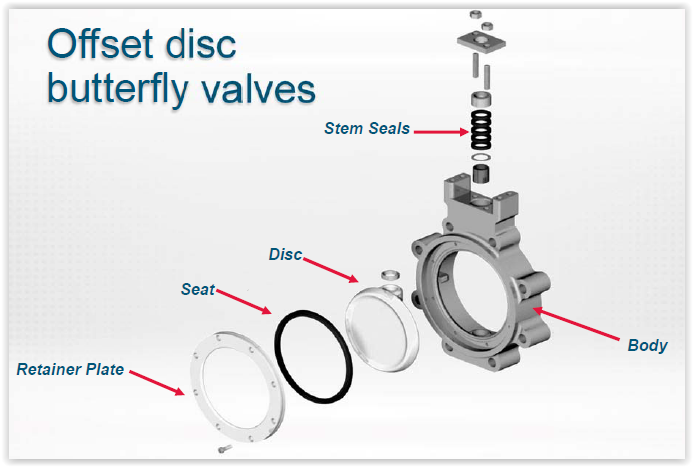

An offset butterfly valve is a type of quarter-turn valve that controls the flow of fluids in pipelines. It features a disc or “butterfly” that rotates around the valve shaft to open, close, or regulate the flow. Unlike traditional concentric butterfly valves, offset butterfly valves have the shaft positioned behind the disc, providing enhanced sealing capabilities and reduced operating torque. This design reduces wear and improves valve performance, making offset butterfly valves suitable for a wide range of applications in industries such as oil and gas, water treatment, and chemical processing.

How to Select the Right Offset Butterfly Valve?

Selecting the right offset butterfly valve involves considering several factors such as the application requirements, fluid characteristics, operating conditions, and industry standards. Evaluate factors such as pressure rating, temperature range, material compatibility, and sealing performance to ensure the valve meets the specific needs of your system. Additionally, consider factors like installation space, maintenance requirements, and budget constraints when making your selection. Consulting with valve manufacturers or experts can also provide valuable insights into choosing the most suitable offset butterfly valve for your application.

Features of Offset Butterfly Valve

- Triple Offset Design: Incorporates three offsets – shaft, disc, and seat – to ensure precise sealing and eliminate rubbing between sealing surfaces, resulting in exceptional leak-tight performance.

- Bubble-tight Shut-off: Provides a reliable bubble-tight shut-off, even in high-pressure and high-temperature applications, ensuring system integrity and safety.

- Bi-directional Sealing: Offers bi-directional sealing capability, allowing the valve to be installed in either direction without compromising performance, providing flexibility in system design.

- Low Operating Torque: Features a low operating torque due to the offset design, resulting in smooth operation and reduced wear on valve components.

- High Temperature Resistance: Constructed from materials such as stainless steel or exotic alloys, providing excellent resistance to high temperatures and corrosive environments.

- Versatile Applications: Suitable for a wide range of applications, including oil and gas, petrochemical, power generation, and water treatment, due to their robust construction and reliable performance.

- Fire-safe Design: Some offset butterfly valves feature a fire-safe design, meeting stringent industry standards for fire safety and reliability in critical applications.

- Long Service Life: Offers a long service life and minimal maintenance requirements due to the durable construction and resistance to wear and corrosion.

Advantages and Disadvantages of Offset Butterfly Valve

Advantages:

- Enhanced Sealing Performance: The triple offset design provides superior sealing capabilities, ensuring bubble-tight shut-off and minimal leakage.

- Low Operating Torque: Offset butterfly valves require lower operating torque compared to other types, resulting in smoother operation and reduced wear on valve components.

- Wide Range of Applications: Suitable for various industries and applications, including oil and gas, petrochemical, water treatment, and power generation, due to their versatility and reliable performance.

- High Temperature and Pressure Resistance: Constructed from materials such as stainless steel or exotic alloys, offset butterfly valves offer excellent resistance to high temperatures and pressures, making them ideal for demanding environments.

- Bi-directional Sealing: Provides bi-directional sealing, allowing installation in either direction without compromising performance, providing flexibility in system design.

Disadvantages:

- Higher Cost: Offset butterfly valves may have a higher initial cost compared to other valve types due to their advanced design and materials.

- Complex Design: The triple offset design of these valves can be more complex than traditional butterfly valves, requiring specialized manufacturing processes and expertise.

- Limited to Clean Service: While offset butterfly valves offer excellent sealing performance, they may not be suitable for applications with particulate-laden or viscous fluids, as these can affect sealing performance and valve operation.

- Maintenance Requirements: Although offset butterfly valves require minimal maintenance compared to other types, maintenance tasks such as seal replacement may be more complex due to the valve’s design.

- Compatibility Concerns: Selecting the right material and configuration for offset butterfly valves is crucial to ensure compatibility with the fluid and operating conditions, which may require careful consideration during the selection process.

The Specifications of Offset Butterfly Valve

| Specification | Details |

|---|---|

| Type | Offset Butterfly Valve |

| Ball Material | Stainless Steel, Carbon Steel, Alloy Steel, etc. |

| Attachment Type | Wafer, Lug, Double Flanged, etc. |

| Thread Standard | ANSI, DIN, BS, JIS, etc. |

| Thread Size | 2 inches – 48 inches (or as per requirement) |

| Body Material | Carbon Steel, Stainless Steel, Alloy Steel, etc. |

| Safe for Use With | Water, Oil, Gas, Chemicals, etc. |

| Handle Type | Manual, Gear-operated, Electric Actuator, etc. |

| Handle Material | Stainless Steel, Carbon Steel, etc. |

| Maximum Working Pressure (psi) | Up to 1500 psi (or as per requirement) |

| Maximum Working Pressure (bar) | Up to 103 bar (or as per requirement) |

| Operating Pressure | As per application requirements |

The Installation Steps for Offset Butterfly Valve

- Preparation:

- Gather all necessary tools and equipment, including wrenches, bolts, gaskets, and any required lifting equipment.

- Ensure that the work area is clean, well-lit, and free from obstructions.

- Valve Inspection:

- Inspect the offset butterfly valve for any signs of damage or defects before installation.

- Verify that the valve size, type, and specifications match the requirements of the application.

- Valve Positioning:

- Identify the optimal location for valve installation based on the system layout and flow direction requirements.

- Ensure that there is adequate clearance around the valve for operation, maintenance, and future access.

- Flange Preparation:

- Clean the flange faces on the pipeline to remove any dirt, debris, or old gasket material.

- Check that the flange faces are flat, smooth, and free from damage to ensure proper sealing.

- Gasket Installation:

- Place a new gasket between the valve flange and the pipeline flange, ensuring that it is centered and aligned properly.

- Use gasket lubricant or sealant as needed to ensure a tight seal and prevent leaks.

- Valve Mounting:

- Lift the offset butterfly valve into position using appropriate lifting equipment or manual handling techniques.

- Align the valve flange with the pipeline flange and insert the bolts through the bolt holes.

- Bolt Tightening:

- Gradually tighten the bolts in a diagonal pattern to ensure even pressure distribution and prevent distortion of the flanges.

- Refer to the valve manufacturer’s specifications for the recommended torque values for bolt tightening.

- Testing:

- Open and close the valve manually or using the actuator to verify proper operation and smooth movement.

- Conduct a pressure test to check for any leaks or irregularities in the valve assembly.

- Final Inspection:

- Inspect the installed valve for any signs of leaks, misalignment, or damage.

- Ensure that all connections are secure and properly sealed.

- Documentation:

- Record the details of the installation process, including valve specifications, torque values, and test results.

- Provide operating instructions and maintenance guidelines for future reference.

The Operation Theory of Offset Butterfly Valve

- Offset Design: The triple offset butterfly valve features a unique design where the shaft is offset from the centerline of the valve seat and the disc is also offset from the shaft axis. This triple offset configuration enables precise sealing and minimizes friction during operation.

- Sealing Mechanism: Unlike conventional butterfly valves, where the disc presses directly against the seat, the triple offset butterfly valve utilizes a conical seating design. This design creates a frictionless sealing mechanism that ensures tight shut-off even in high-pressure and high-temperature applications.

- Metal-to-Metal Sealing: Triple offset butterfly valves typically employ metal-to-metal sealing between the disc and seat. This robust sealing method offers superior performance and durability, making the valve suitable for demanding applications in industries such as oil and gas, petrochemical, and power generation.

- Torque Transmission: The offset design of the valve reduces the contact area between the disc and seat during operation, resulting in lower operating torque. This allows for smooth and efficient valve operation, even in large-diameter valves and high-pressure systems.

- Reduced Wear: By minimizing friction and wear between the sealing components, triple offset butterfly valves offer extended service life and reduced maintenance requirements compared to other valve types.