What are the Protective Measures to the Abnormal Pressure Surge of Gate Valves

full port valve

blowdown valve

The Perils of Excessive Pressure: Protecting the Valve’s Integrity

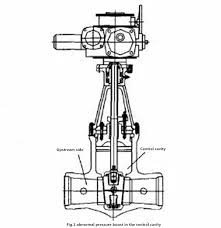

The strength of a gate valve’s shell, bonnet, and stem is designed to withstand the nominal pressure of the system. However, when abnormal pressure spikes occur, the opening pressure can increase dramatically, resulting in heightened stress on critical components. If the actual stress overwhelms the allowable stress, parts with high stress can fracture, leading to a failed opening, a damaged valve gate, or even a scrapped machine.

Safeguarding the Safety System: Preventing Catastrophic Failures

The pressure-bearing pieces, such as the shell and bonnet, are especially vulnerable to over-pressurization. This can cause these critical components to breach, leading to sudden, uncontrolled leaks of the fluid medium. If the medium is a high-temperature, toxic, or otherwise hazardous gas, the consequences can be catastrophic, potentially resulting in significant damage and loss of life.

Maintaining Operational Reliability: Mitigating System Disruptions

Gate valves are the linchpin of industrial control systems, ensuring the smooth operation of various processes. When the valve’s operation fails, the entire system must be shut down for maintenance, leading to substantial direct and indirect financial losses.

Proactive Solutions: Preventing Abnormal Pressure Build-up

To eliminate the threat of abnormal pressure in the valve’s internal cavity, several effective and commonly adopted solutions can be implemented:

1. Pressure Relief Hole

The pressure relief hole, strategically placed inside the valve, allows the increased pressure in the middle cavity to be automatically released to the upstream, maintaining a balanced pressure on both sides and preventing abnormal pressure build-up.

2. Bypass Pressure Relief

For existing gate valves, an external bypass can be installed, connecting the middle cavity to the upstream. When the main gate is closed, the bypass block valve can be opened to reduce the pressure in the cavity before opening the main gate valve.

3. Dedicated Relief Valve

A special relief valve can be attached to the external cavity, set to discharge at the rated working pressure of the main gate valve. This ensures that any over-pressurization is automatically relieved, maintaining the safe operation of the gate valve.

Importance of Proper Installation and Debugging

Careful attention must be paid to the installation and debugging processes, especially for electric valves. Minimizing the switch-off torque and accounting for thermal expansion of the stem can prevent the valve’s wedge from becoming stuck, a common issue in high-temperature, high-pressure, and large-diameter gate valves.