Introduction to Trunnion Mounted Ball Valve

ball valve vs globe valve

ansi 300 pressure rating

Overview of Trunnion Mounted Ball Valve

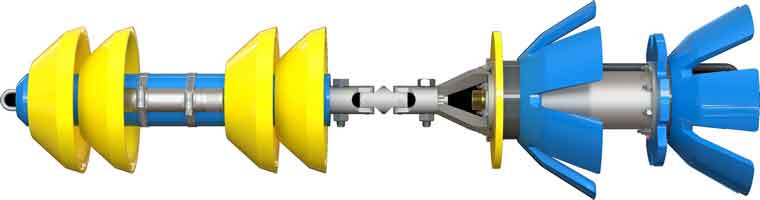

Trunnion Mounted Ball Valve is a versatile solution for cutting off or connecting the medium in pipelines. Chaoda Group offers forged steel Trunnion Mounted Ball Valves that can be applied to a wide range of media, including water, steam, oil, nitric acid, acetic acid, oxidizing medium, urea, and more. These valves can be driven by manual, worm gear, pneumatic, or electric mechanisms, and typically use flange or butt welding connections.

Ball Valve Fundamentals

The ball valve uses a ball with a circular through-hole as the opening and closing part. Under the drive of the valve stem, the ball rotates around the center of the valve stem 90 degrees to complete the opening and closing function. There are several types of ball valves:

- Floating Ball Valve and Trunnion Mounted Ball Valve

- Cast Steel Ball Valve and Forged Steel Ball Valve

- Soft-Sealed Ball Valve and Metal Hard-Sealed Ball Valve

- Separate Parts Type Trunnion Mounted Ball Valve, Upper Trunnion Mounted Ball Valve, and Full Welded Ball Valve

Application Scope of Trunnion Mounted Ball Valve

Trunnion Mounted Ball Valve is better than floating ball valve in oil, natural gas, coal and ore mining, refining and pipeline transportation systems, as it can withstand higher temperatures and pressures.

Trunnion Mounted Ball Valve, with its hardfacing sealant, can be used to open and close pipes in chemical products, pharmaceuticals, and food products, as well as in the power production systems of hydropower, thermal power, and nuclear power.

In urban and industrial environments, such as water supply and drainage, heating, gas supply, and farmland irrigation and drainage systems, where the medium is mostly non-corrosive water, ordinary Trunnion Mounted Ball Valve can meet the daily needs. Trunnion Mounted Ball Valve has also been widely used in the production system of gold treatment.