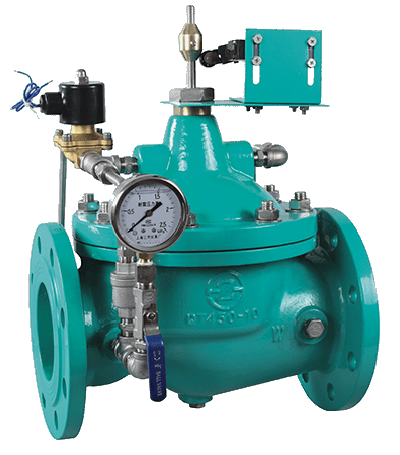

Air Relief Valve

The Application of Air Relief Valve

Rotork Air Relief Valve is a leading brand known for its high-quality air relief valves for various applications such as fuel pressure relief valve, pressure relief valve for boiler, and pressure washer pressure relief valve. These valves play a crucial role in regulating pressure levels by releasing excess pressure to ensure the safety and efficiency of different systems. The fuel pressure relief valve safeguards fuel systems from overpressure situations, while the pressure relief valve for boiler protects boiler systems from potential damage. Similarly, the pressure washer pressure relief valve helps maintain optimal pressure levels in pressure washer systems. With Rotork’s expertise in valve technology, their air relief valves provide reliable and precise pressure control in a wide range of applications.

What Is Air Relief Valve?

An Air Relief Valve is a type of valve designed to release excess air or gas from a system to prevent airlocks and ensure smooth operation.

How Does Air Relief Valve work?

An Air Relief Valve operates by automatically releasing trapped air or gas from a system, allowing it to escape and maintaining optimal pressure levels for efficient system performance.

Features of Air Relief Valve

- Efficient Air Release: Air relief valves efficiently release trapped air or gas from systems, preventing airlocks and ensuring smooth operation.

- Automatic Operation: These valves feature automatic mechanisms that activate when air or gas needs to be released, reducing the need for manual intervention.

- Pressure Regulation: Air relief valves help regulate pressure levels within systems by releasing excess air, maintaining optimal operating conditions.

- Durable Construction: Designed for longevity, these valves are built from durable materials to withstand varying environmental conditions and ensure reliable performance.

- Versatile Applications: Air relief valves find applications in various industries, including water systems, HVAC systems, and pipelines, providing essential air release functions for different systems.

Advantages of Air Relief Valve

- Prevents Airlocks: Air relief valves prevent airlocks in systems by releasing trapped air or gas, ensuring continuous operation.

- Maintains System Efficiency: By regulating air pressure, these valves help maintain system efficiency and performance.

- Protects Equipment: Air relief valves protect equipment from damage caused by excess air pressure or airlocks.

- Improves System Lifespan: By preventing air-related issues, these valves contribute to the longevity of system components.

- Enhances Safety: Ensuring proper air release, air relief valves enhance system safety by preventing pressure build-up and potential hazards.

The Specifications of Air Relief Valve

| Specification | Details |

|---|---|

| Type | Air Relief Valve |

| Ball Material | Stainless Steel, Brass, or PTFE |

| Attachment Type | Threaded, Flanged, or Welded |

| Thread Standard | N/A |

| Thread Size | Varies |

| Body Material | Aluminum, Cast Iron, or Stainless Steel |

| Safe for Use With | Various systems and applications |

| Handle Type | N/A |

| Handle Material | N/A |

| Max. Working Pressure (psi) | Varies |

| Max. Working Pressure (bar) | Varies |

| Operating Pressure | Varies |

The Parameter of Air Relief Valve

- Type: Air Relief Valve

- Ball Material: Stainless Steel, Brass, or PTFE (Polytetrafluoroethylene)

- Attachment Type: Threaded, Flanged, or Welded

- Thread Standard: N/A

- Thread Size: Varies

- Body Material: Aluminum, Cast Iron, or Stainless Steel

- Safe for Use With: Various systems and applications

- Handle Type: N/A

- Handle Material: N/A

- Maximum Working Pressure (psi): Varies

- Maximum Working Pressure (bar): Varies

- Operating Pressure: Varies

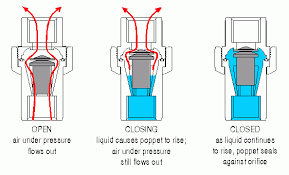

The Operation Theory of Air Relief Valve

The operation theory of an Air Relief Valve involves the valve opening to release excess air or gas when the pressure reaches a certain level, serving as a 3/4 pressure relief valve or a pneumatic pressure relief valve. This action helps prevent overpressure situations within systems by allowing the trapped air to escape, maintaining optimal pressure levels for efficient operation.

The Parameters Table of Air Relief Valve

| Part | Material |

|---|---|

| Valve Body | Stainless Steel, Brass, Cast Iron, or Aluminum |

| Valve Seat | Stainless Steel, Brass, or Synthetic Material |

| Valve Ball | Stainless Steel, Brass, or PTFE (Polytetrafluoroethylene) |

| Spring | Stainless Steel or High-Grade Alloy |

| Stem | Stainless Steel or Brass |

| Housing | Aluminum, Cast Iron, or Steel |

| Gasket | Rubber or Synthetic Material |

| Connection | Threaded, Flanged, or Welded |