Axial Check Valves – Axial Flow Check Valve Manufacturers | ZECO Valvevalves in oil and gas

pratt butterfly valves

2 butterfly valve

3 inch butterfly valve

Table of Contents

- What is an Axial Check Valve?

- Why are Axial Check Valves used and play a vital role?

- How are Axial Flow Check Valves used?

- Working principle of Axial Flow Check Valves

- Advantages of Axial Check Valves

- 1. Axial flow

- 2. Low pressure loss

- 3. Tight shut-off

- 4. Easy opening and stable operation

- 5. Non-slamming operation

- 6. Maintenance-free

- Difference between Swing Check Valves and Axial Check Valves

- Swing check valve

- Axial check valve

What is an Axial Check Valve?

The main purpose of an axial flow check valve is to allow flow in one direction while prohibiting or stopping flow in the opposite direction. It is normally stationary in the closed position. The performance of axial check valves in terms of low pressure loss, stable operation, and dynamic behavior play a vital role in critical check applications such as the protection of rotating equipment and systems.

Why are Axial Check Valves used and play a vital role?

When the flow in a pipeline is reversed, this can cause a hydraulic shock wave to pass through (also known as a water hammer). This can cause serious damage to equipment in the pipeline if nothing is done to prevent it. Introducing the correct check valve, in the fully closed position in the event of a reversal of flow, can prevent this from happening and causing serious problems in the field.

A valve that prevents water hammer and rapid closure without a banging sound is known as an axial flow check valve.

How are Axial Flow Check Valves used?

The axial check valve is specifically designed for fast backflow systems, where backflow is a constant problem. It is classified as a non-slam check valve as there is no slamming when the valve closes, meaning that no excess pressure spikes are generated. Most axial flow check valves are spring loaded and have a low mass disc, which facilitates a rapid dynamic response to a reduction in flow. As there is a single disc and spring, the forces are balanced when the disc is open, resulting in a uniform flow.

Working principle of Axial Flow Check Valves

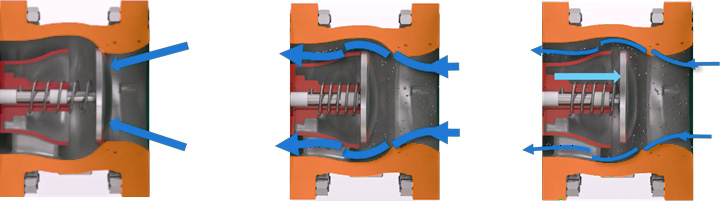

When the pressure difference between the upstream and downstream of the valve exceeds the rupture pressure of the spring, the disc will move and allow flow. The flow area of the valve steadily decreases to the seat diameter; this is the venturi design.

As a result of the venturi design, the reduced flow area increases the dynamic pressure and reduces the static pressure, allowing the valve to open fully and quickly. The spring is chosen to allow the disc to open fully and stabilize on its backstop under normal flow conditions.

When the flow rate is significantly reduced, the spring responds to the reduced flow rate in advance.

Advantages of Axial Check Valves

1. Axial flow

The streamlined flow path through the full port expanded body prevents turbulence, erosion, and vibration, which eliminates the process downtime and maintenance cost.

2. Low pressure loss

The full port passage and high-pressure recovery of the venturi-shaped body lead to lower pressure loss. This saves the cost of pumps.

3. Tight shut-off

Tight shut-off is achieved by a metal-to-metal seal between the disc and the valve seat. This seal is unaffected by material erosion and deformation (e.g. soft seal).

4. Easy opening and stable operation

The low static pressure in the throat area of the venturi shape creates a pressure differential across the disc, resulting in the easy opening. Axial check valves respond smoothly to changes in flow and remain stable when they should.

5. Non-slamming operation

The spring-assisted design ensures ultra-fast closing, with virtually no backflow or pressure surges in critical applications such as multi-pump systems or LNG trains.

6. Maintenance-free

The internal construction is based on the application of sound basic mechanical engineering principles. As a result, ZECO axial check valves do not require any maintenance.

Difference between Swing Check Valves and Axial Check Valves

Swing check valve

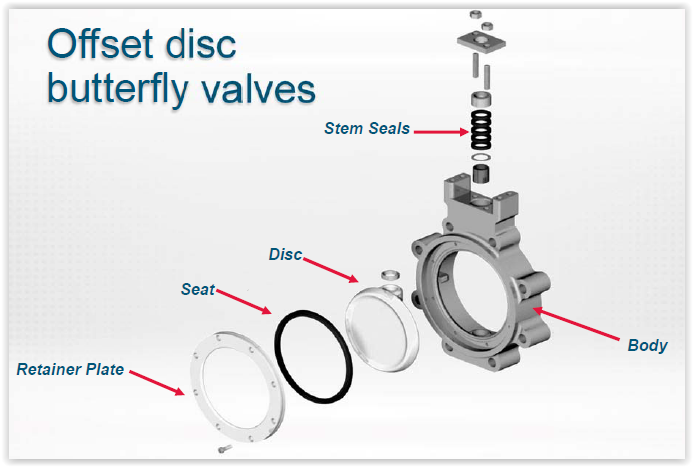

A fairly basic type of valve, swing check valves are butterfly shaped, meaning that the disc – the part that stops the flow of fluid – opens and closes on a hinge or trunnion. Although these valves are ideal in some applications, swing check valves are being phased out due to commonly recurring problems such as turbulence and water hammer.

Axial check valve

The axial flow check valve is an updated design of the swing check valve. The disc in the valve is held in place by a spring. This centers the movement of the disc, allowing smoother fluid flow and reactive opening and closing without the sudden movements that cause the water hammer.

If any inquiries, you can contact ZECO Valve. Email: commercial@zecovalve.com

Related Tags :

ZECO Valve

NBR Butterfly Valve

Gate Valve vs Ball Valve

What is a Globe Valve?

Gate Valve Repair

Manual Operate Gate Valve Manufacturer

What are Globe Valves?

Ten articles before and after

How Does Resilient Seated Butterfly Valve Work? – Zeco Valve

What is the difference between a knife gate valve and slide gate valve?

How Does Flanged Gate Control Valve Work – Zeco Valve

Valve Technology Questions and Answers I

Best 10 Ball Valve Manufacturers in USA – Zeco Valve

9 Ways to Extend the Service Life of Industrial Valves – Zeco Valve

Characteristics of valve manufacturing process | Industrial Valves Manufacturers

What is the difference between globe valve and stop check valve?

How to chose valve actuator?

Ball Valve vs. Gate Valve: Which is Better? – Zeco Valve