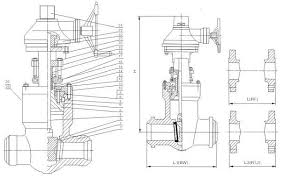

High Pressure Gate Valve

The Application of High Pressure Gate Valve

Rotork High Pressure Gate Valve is engineered to withstand rigorous conditions, ensuring reliable performance in demanding environments. Designed to handle high-pressure applications, it provides robust sealing and efficient flow control. The valve’s sturdy construction and durable materials, including ball valve 1-1/2 stainless steel, make it suitable for critical operations where safety and reliability are paramount. Rotork’s advanced engineering ensures precise operation and long-term durability, meeting the stringent requirements of various industries. Whether it’s in oil and gas, petrochemical, or industrial settings, Rotork High Pressure Gate Valve offers superior performance and exceptional reliability. Cameron High Pressure Gate Valve shares similar features and is also recognized for its quality and performance in high-pressure applications.

What Is High Pressure Gate Valve?

- Purpose: High Pressure Gate Valves are built to handle extreme pressure environments.

- Construction: These valves are made of strong materials like stainless steel, ensuring durability.

- Reliability: They offer dependable performance even under harsh conditions.

- Sealing: Special seals are employed to prevent leaks, enhancing safety.

- Applications: Widely used in industries like oil and gas, where high pressures are common.

- Performance: Known for their precise control and long-lasting service life.

- Variants: Different models cater to various pressure requirements, offering flexibility.

- Recognition: Highly regarded for their quality and effectiveness in demanding settings.

- Industry Standard: Comply with industry standards to ensure compatibility and reliability.

Features of High Pressure Gate Valve

- Inspection: ZECO’s high pressure gate valves undergo rigorous inspection processes. Visual inspection identifies any visible welding defects, ensuring quality. Further testing, such as PT, is conducted to detect hidden cracks and assess sealing surface hardness.

- Replaceable Stem Nut: The stem nut of ZECO’s high pressure gate valve can be easily replaced while the valve is in operation, ensuring efficient maintenance.

- Backseat Design: ZECO’s high pressure gate valve features a backseat design that relieves pressure on the stem packing when fully seated, enhancing safety and prolonging the valve’s lifespan.

- Seal Welded Seat Rings: The seat rings of ZECO’s high pressure gate valve are seal welded, providing a secure, bubble-tight joint. This ensures reliable performance and prevents leaks, even under high pressure conditions.

The Specifications of High Pressure Gate Valve

| Specification | Description |

|---|---|

| Type | High Pressure Gate Valve |

| Ball Material | N/A |

| Attachment Type | N/A |

| Thread Standard | N/A |

| Thread Size | N/A |

| Body Material | Steel, Stainless Steel, Alloy Steel |

| Safe for Use With | High-pressure fluid systems |

| Handle Type | Handwheel, Gear Operator, Actuator |

| Handle Material | Steel, Stainless Steel, Alloy Steel |

| Maximum Working Pressure | Varies based on size and configuration |

| Maximum Working Pressure | Varies based on size and configuration |

| Operating Pressure | Varies based on application |

The Parameter of High Pressure Gate Valve

- ZECO high pressure gate valve undergoes visual inspection (VT) for welded products to detect welding defects like cracks, edging, and molding defects.

- Post visual inspection, penetrant testing (PT) is conducted to check for cracks on the sealing surface and to assess surface hardness.

- The stem nut of ZECO high pressure gate valve is designed to be replaceable in line for easy maintenance.

- It features a backseat design to relieve pressure on the stem packing when fully seated.

- Seat rings of ZECO high pressure gate valve are seal-welded to ensure a bubble-tight joint.

The Operation Theory of High Pressure Gate Valve

The operation theory of High Pressure Gate Valve involves the movement of a gate to control the flow of fluid. When the valve is closed, the gate blocks the flow path, providing a tight seal. To open the valve, the gate is raised, allowing fluid to pass through. This process is facilitated by the stem, which connects the gate to the actuator. The 1 1/2 plastic ball valve functions differently, using a spherical ball with a hole to regulate flow. However, both valves serve the same purpose of controlling fluid flow in pipelines. The Barton 200AS and 1 8 ball valve are examples of different valve types that operate on similar principles, illustrating the versatility of valve technology.

The Parameters Table of High Pressure Gate Valve

| Parameter | Specification |

|---|---|

| Type | High Pressure Gate Valve |

| Ball Material | Not Applicable |

| Attachment Type | Not Applicable |

| Thread Standard | Not Applicable |

| Thread Size | Not Applicable |

| Body Material | [Specify Material] |

| Safe for Use With | High-pressure fluids |

| Handle Type | Not Applicable |

| Handle Material | Not Applicable |

| Maximum Working Pressure | [Specify Pressure] psi/bar |

| Operating Pressure | [Specify Pressure] psi/bar |