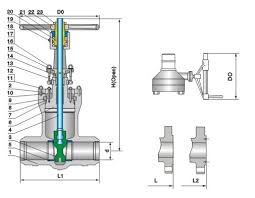

1500LB Gate Valve Pressure Seal Bonnet Butt Welded A 216 WCB 8 INCH

Standards

Design and Manufacture: API 600

Face to Face: ASME B16.10

Flanged Ends : ASME B16.5

Butt Welded Ends: ASME B16.25

Test and Inspection:API 598

The Application of 1500LB Gate Valve

The application of 1500LB Gate Valves is crucial in various industrial sectors, particularly in the petrochemical and high-pressure environments. High Pressure 1500 LB Gate Valves engineered by renowned brands like Cameron are designed to withstand extreme pressure conditions, ensuring reliable performance and safety. These valves are widely utilized in Petrochemical 1500 LB Gate Valve applications, where the ability to control and regulate the flow of fluids and gases under high-pressure is paramount. With their robust construction, advanced sealing systems, and corrosion-resistant materials, Cameron’s 1500LB Gate Valves provide precise flow control and dependable shut-off capabilities, making them an indispensable component in mission-critical industrial infrastructure.

What Are The Types Of 1500LB Gate Valve?

Solid Wedge Gate Valve:

These feature a solid, single-piece wedge that provides a tight seal when the valve is closed. They are known for their reliability and are commonly used in high-pressure applications.

Flexible Wedge Gate Valve:

Flexible wedge gate valves have a two-piece wedge design that allows the valve to adapt to any slight misalignment in the piping system. This design helps ensure a reliable seal.

Parallel Slide Gate Valve:

Parallel slide gate valves use a sliding gate mechanism to open and close the valve. This design allows for a full, unobstructed flow path when the valve is open.

Expanding Gate Valve:

Expanding gate valves use a two-part wedge that expands to create a tight seal when closed. This design helps compensate for wear over time and provides a reliable shut-off.

Slab Gate Valve:

Slab gate valves feature a single, solid gate that seals against resilient seats. They are a simpler and more economical option for certain high-pressure applications.

What Is 1500LB Gate Valve?

A 1500LB gate valve is a type of industrial valve designed to withstand high-pressure applications, with a pressure rating of 1,500 pounds per square inch (psi). These valves are commonly used in the oil and gas, petrochemical, power generation, and other heavy industrial sectors where the ability to control and isolate the flow of fluids and gases under extreme pressure conditions is crucial. 1500LB gate valves typically feature a robust, forged or cast metal body construction, with a sliding gate mechanism that opens and closes to regulate the flow. The high pressure rating allows these valves to be deployed in systems operating at pressures up to 1,500 psi, providing reliable performance and safety in demanding industrial environments. The specific design, materials, and features of 1500LB gate valves can vary depending on the manufacturer and the application requirements.

How to Select the Right 1500LB Gate Valve?

When selecting the right 1500LB gate valve, there are several key factors to consider. First, it’s important to determine the specific pressure, flow, and media compatibility requirements of the application. This will help narrow down the valve type, such as solid wedge, flexible wedge, or parallel slide. Other important criteria include the valve’s end connections, material compatibility, and any special features needed, such as fire-safe design or cryogenic service capabilities. Working closely with a reputable valve manufacturer or distributor can ensure the 1500LB gate valve chosen will meet the application’s performance and safety standards. Careful consideration of these selection factors will help end-users identify the most appropriate 1500LB gate valve solution for their high-pressure industrial systems.

Features of 1500LB Gate Valve

Pressure Rating

1500LB gate valves are designed to withstand pressure up to 1,500 pounds per square inch (psi), making them suitable for high-pressure industrial applications.

Materials

These valves typically feature a forged or cast metal body, with components like the gate, seats, and seals made from durable materials like stainless steel to ensure reliable performance.

Valve Designs

Common 1500LB gate valve designs include solid wedge, flexible wedge, parallel slide, and expanding gate configurations, each offering specific advantages for different application requirements.

Flow Control

The sliding gate mechanism provides precise control over fluid and gas flow, allowing for accurate regulation and shut-off capabilities in the system.

Corrosion Resistance

The use of corrosion-resistant materials helps 1500LB gate valves withstand harsh operating environments, including exposure to aggressive media.

Operational Safety

Features like fire-safe design and emergency shut-off capabilities ensure 1500LB gate valves can maintain safety in critical industrial processes.

Advantages and Disadvantages of 1500LB Gate Valve

Advantages of 1500LB Gate Valve:

High Pressure Capability: 1500LB gate valves are designed to withstand extremely high pressures up to 1,500 psi, making them suitable for demanding industrial applications.

Robust Construction: The forged or cast metal body, along with durable internal components, provide a rugged and reliable valve solution.

Versatile Design: Available in various configurations, such as solid wedge, flexible wedge, and parallel slide, allowing for customization to specific application requirements.

Precise Flow Control: The sliding gate mechanism enables accurate regulation and shut-off of fluid and gas flow.

Corrosion Resistance: The use of corrosion-resistant materials helps these valves withstand harsh operating environments.

Operational Safety: Features like fire-safe design and emergency shut-off capabilities enhance safety in critical industrial processes.

Disadvantages of 1500LB Gate Valve:

Higher Cost: 1500LB gate valves, due to their robust construction and specialized design, are generally more expensive than lower-pressure valve options.

Larger Size and Weight: The high-pressure rating of these valves often translates to a larger physical size and heavier weight, which can complicate installation and handling.

Potential for Leakage: Over time, the sliding gate mechanism and seals in 1500LB gate valves may experience wear, increasing the risk of potential leaks if not properly maintained.

Limited Flow Capacity: Compared to other valve types, such as ball valves, the flow capacity of gate valves can be relatively lower, which may be a consideration for certain applications.

The Specifications of 1500LB Gate Valve

| Specification | Details |

|---|---|

| Type | Solid Wedge Gate Valve |

| Ball Material | N/A (Gate Valve) |

| Attachment Type | Flanged |

| Thread Standard | ASME B16.5 |

| Thread Size | 2 inch |

| Body Material | Forged Carbon Steel |

| Safe for Use With | Oil, Gas, Steam, Water |

| Handle Type | Handwheel |

| Handle Material | Carbon Steel |

| Maximum Working Pressure (psi) | 1500 |

| Maximum Working Pressure (bar) | 103.4 |

| Operating Pressure | Up to 1500 psi |