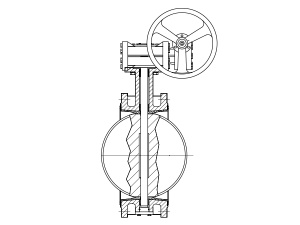

Flanged Butterfly Valve

The Application of Flanged Butterfly Valve

The Flanged Butterfly Valve is a crucial component in fluid control systems, crafted through a rigorous industrial valve manufacturing process. Unlike the world’s largest gate valve or the ITT Barton 318C and 227 manual, it offers compact design and efficient operation. With trusted brands like Cameron renowned for brass ball valves and butterfly valve seats, and suppliers like SKG Pneumatics Inc, providing precision components, the Flanged Butterfly Valve ensures reliability in various applications. Its versatile design makes it suitable for use in pipelines, HVAC systems, water treatment plants, and more. The valve’s flanged connection enables easy installation and maintenance, ensuring seamless integration into diverse industrial settings.

Features of Flanged Butterfly Valve

- Bidirectional sealing, no flow direction of the medium;

- Valve body vulcanized EPDM, reliable sealing;

- A dial with an opening indication showing the position of the disc switch;

- Flow characteristics straight line, good regulation performance.

The Parameter of Flanged Butterfly Valve

- Pressure Rating: Flanged Butterfly Valves typically have a pressure rating ranging from Class 150 to Class 600.

- Temperature Range: Capable of operating within a wide temperature range, from -50°F to 500°F (-46°C to 260°C).

- Size Range: Available in various sizes, typically ranging from 2 inches to 48 inches or larger.

- Design Standards: Manufactured in compliance with industry standards such as API 609, ASME B16.34, and ISO 5752.

- Material: Constructed from high-quality materials such as ductile iron, carbon steel, stainless steel, or exotic alloys for corrosion resistance and durability.

- Sealing System: Equipped with resilient or metal-to-metal seating for tight shut-off and low leakage rates.

- Actuation: Compatible with various actuation methods including manual, electric, pneumatic, or hydraulic actuators.

- End Connections: Flanged ends for easy installation and connection to pipeline systems.

The Operation Theory of Flanged Butterfly Valve

The operation theory of Flanged Butterfly Valve involves a disc that rotates on a shaft to control flow. Unlike globe valve vs ball valve, it offers quick on/off control. Similar to Intec Duoball, it ensures efficient fluid control. Used in various industries like cooling tower valves company, it maintains tight shut-off and low leakage rates, meeting industry API and rating standards. Unlike the Barton 450C, it employs a different design. It’s important to note that its operation differs from that of a knife gate valve symbol.

The Parameters Table of Flanged Butterfly Valve

| Parameter | Description |

|---|---|

| Material | Ductile Iron, Carbon Steel, Stainless Steel, etc. |

| Pressure Rating | Class 150 to Class 600 |

| Temperature Range | -50°F to 500°F (-46°C to 260°C) |

| Size Range | 2 inches to 48 inches or larger |

| Design Standards | API 609, ASME B16.34, ISO 5752 |

| Sealing System | Resilient or Metal-to-Metal Seating |

| Actuation | Manual, Electric, Pneumatic, Hydraulic |

| End Connections | Flanged Ends |

Relevant Information about Flanged Butterfly Valve

- Rotor: The disc that rotates inside the valve to control the flow of fluid.

- Stator: The stationary part of the valve that supports the rotor and maintains alignment.

- Universal Joint: Not typically present in butterfly valves.

- Shaft Seal: Prevents leakage along the valve shaft, ensuring a tight seal.

- Driving System: Manual operation or actuation using electric, pneumatic, or hydraulic systems to control the position of the rotor.