Where are Valves Used?

hayward butterfly valve

bray butterfly valve series 31

knife gate valve symbol

butterfly valve torque chart

Valves direct or control the media flow through any system by starting, stopping, or partially obstructing the passage of fluid. They are of so many types, all having the same function but in different conditions.

Valves are involved in almost every industrial process, including power generation, food, chemical, pharmaceutical and plastic manufacturing, processing of oils, gases, and petroleum, etc. However, the selection of valves determines the success or failure of any operation. In this article, you will know about some of the major industries where valves are used:

Food and beverage industry

The food and beverage industry undergoes multiple operations with strict regulations. Valves play a critical role in fulfilling strict regulatory demands and achieving the best quality products. Choice of the valve should be right to ensure safety and proper functionality. They do not encounter high pressure and corrosive substances in the food and beverage industry. Everything from cookies or cereals to canned fruit or pastry is either steamed, pasteurized, or dehydrated before packing. Such processes can be effectively carried out using ball valves.

Valves for the food and beverage industry can be categorized into two types: Direct valves to handle contents directly and utility service valves for regulation of water, steam, etc. Direct valves are made of steel and regulated according to FDA guidelines. Although utility valves do not contact with contents, they are also maintained under specific guidelines to guarantee safety.

Valves are so important as they block the entry of unwanted materials such as pathogens into food. In the food and beverage industry, sanitary valves are clean, sterile and prevent bacterial contamination. Sanitary ball valves are used for beverage processing due to the high rangeability and design of the regulating elements. Moreover, sanitary valves also have applications in brewing, dairy processing, wine and spirits making.

Medical devices and the pharmaceutical industry

Over the past few decades, medical advancements have sought to develop new products and techniques to combat rare diseases. Therefore, pharmaceutical industries must have hygienic and safer manufacturing processes. Sanitary valves are best to carry out the clean and sterile medical production process. The chemical processing may involve reactions using heat and pressure. Therefore, the valves must be able to withstand such conditions to prevent leakage and contamination.

In medical device development, proportional valve offers cost-effective, dependable and compact solutions for rapid response and persistent control. The engineers must consider medium and variables to be controlled while selecting a proportional valve for a medical device. This valve can be used in:

- Oxygen concentrators

- Patient simulators

- Shock wave therapy

- Positive End-Expiratory Pressure (PEEP) control

- Anaesthesia and ventilator gas mixing

- Ventilator patient “delivery” valve

- Leak testing in medical components and packaging

- Surgical instruments and patient monitoring

- Clinical diagnostic equipment

Medical ventilators serve as a lifesaver in modern medical care, and valves are the secret behind their working. They deliver an accurate concentration of gas with a suitable flow rate to the patient. Plus, solenoid valves provide excellent patient care by regulating the oxygen flow rate with great speed and accuracy. They also have applications in dialysis machines.

Oil and gas industry

Oil and gas operations are getting more complex every year. Like other industries, valves also have major applications in the oil and gas industry. For upstream operations, valves are required to control the flow of crude oil and natural gas from a high-pressure environment to the top of the well. The valves used for upstream operations must be strong, durable, leak-proof and non-corrosive. Usually, gate valves and ball valves are commonly used for these operations.

In midstream operations, where oils and gases are transported through pipeline systems, isolation valves are so important for safe operations. In downstream applications such as refining, high temperature and extreme pressure can damage valves. High quality, sturdy gate valves are used in downstream operations.

Cryogenic industry

Valves used in the cryogenic industry are specially built for very cold applications. Such valves are designed to control the transportation and storage of cryogenic gases safely. Cryogenic valves are quite different from valves used in other industries because they can work efficiently even at temperatures as low as – 196°C and pressure as high as 750 psi. These valves are kept in the natural closed position to contain the cryogenic gases secure. A high-pressure rating opens such valves and allows the flow of gases until the pressure drops, and the valve goes back to a sealed position. Cryogenic valves prevent the leakage of cryogenic sensitive gases to avoid any accidental damage.

Power industry

In the power industry, valves serve to enhance power generation efficiency and boost power performance. The valves may be small in size, but they play a pivotal role in power plants. There are many kinds of valves that can be used in power plants for different roles. Pressure seal gate valves, global valves, check valves, ball valves, and butterfly valves are commonly employed in the power industry.

Automotive industry

In automobiles, valves are responsible for controlling the flow of gas, oil, and other fluids. The performance of several systems of automobiles depends on automotive valves. Different kinds of valves are placed to perform various vehicle functions such as cooling, door locks, brakes and fuel circulation. Such valves include brake combination valve, engine valve, exhaust valve and gas recirculation valve. The solenoid valve can manage medium circulation in an automobile or linear motion of the plunger, which is used in various functions such as door locks, fuel valve control, steering locks, starter motors, and anti-lock braking system (ABS).

In a car’s engines, mainly two valves are used an inlet valve and an exhaust valve. Fuel enters the cylinder through the inlet valve while the exhaust valve allows the escape of burned gases. Engine valves are also known as poppet or mushroom valves.

Mining

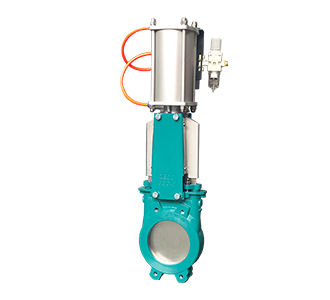

Mining operations heavily rely on valves. Slurry valves, knife gate valves, butterfly valves, ball valves and check valves are extensively used in mining for:

- Pumping Stations

- Slurry Transport

- Pipelines

- Separation

- Isolation

- Dewatering

- Intermediate Station

- Terminal Stations

- Thickeners

- Air Release

Furthermore, mineral extraction, processing, and refining are considered to be the most challenging mining functions for valves. In mining, valves are subjected to incredibly harsh conditions. Hence, valves are formed from abrasion-resistant material, lined, and coated with suitable materials for proven performance.

Agriculture

Agriculture industry

In agriculture or farming, solenoid valves are used to irrigate crops, plants, bushes and gardens—these valves are made up of stainless steel to minimize corrosion or rust in irrigation operations. There is a drain screw present at the valve to prevent pipe freezing.

Marine industry

Valves are also used in the marine industry. Ships need to produce power, regulate wastewater and control HVAC. Different types of valves are used to manage and process wastewater, regulate the power supply, store any liquid cargo and fire fighting service etc. The ship’s size and applications determine the type and number of valves used in it.

Household

Valves are already playing a key role in our household routine. Every household is connected with a water supply and a sewage system. Valves, along with some other equipment, start, stop and regulate the flow from water taps. A release valve allows the air to escape from the radiator attached to the central heating system. A garden hose only works when connected to a tap that can be turned on and off through a rotary valve.

Laundry and textile industry

Solenoid valves also have applications in the textile industry where clothes require to be folded instantly and accurately. In such applications, valves must be quick, reaction and response time must be less than 25 ms.

Fire protection services

Butterfly valves are lightweight and provide cost-effective control over water flow to the pipes serving fire sprinkler and standpipe systems. A position indicator outside the valve plays a crucial role in keeping fire protection operational. It helps fire professionals to identify the closed valve and re-open it.

Aerospace industry

In the aerospace industry, ball valves are highly used in turbines. They maintain the bubble-tight seal to ensure the optimum efficiency of turbines even in high pressures and temperatures. Besides, ball valves can be observed in the construction of rockets, planes, helicopters, and other aerospace vehicles. The reliability and efficiency of ball valves make them incredibly important in the aerospace industry.

Summary

Valves are a blessing because they seem to have managing operations in almost every industry. Without them, mankind wouldn’t have reached the place where it is right now. There is the valve for every operation, you just have to select the right one for your need.