Knife Valve vs Gate Valve, Knife Gate Valve & Slab Gate Valve Applicationgear operated butterfly valve

zurn flush valve

sloan royal flush valve

355n

3 way control valve

toilet flush valve kit

Large factories usually adopt some large cutting tools. Since the 1980s, all kinds of gate valves have developed rapidly in less than 20 years. Its scope of use continues to expand to all walks of life. Now it can be seen in industries such as coal preparation, gangue discharge, and slag discharge.

So, what are the differences between knife gate valve and slab gate valve in structure and use? Let’s learn about it.

Table of Contents

- What is a Knife Gate Valve?

- How does a Knife Gate Valve work?

- What is a Knife Gate Valve used for?

- Advantages of Knife Gate Valves

- Knife Gate Valve Application

- What is a Slab Gate Valve?

- How does a Slab Gate Valve work?

- Advantages of Slab Gate Valves?

- Slab Gate Valve Application

- Knife Valve vs Gate Valve

- Different Design Standard

- Different End Type

- Different Seat Structure

- Different Function

- Different Installation, Operation & Application

- Gate Valve Application

This type of product belongs to the closed type, its movement direction is perpendicular to the fluid direction, and the switch of knife gate valve is basically the full switch. Therefore, regulating the flow relationship is the main purpose of this kind of product.

What is a Knife Gate Valve?

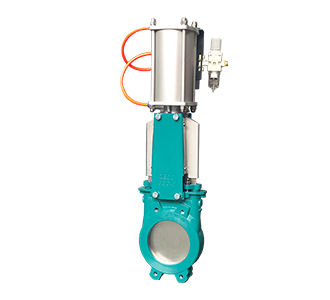

Knife gate valves are designed mainly for on-off and isolation services in systems with high content of suspended solids. Knife gate valves are especially beneficial for handling slurry in addition to viscous, corrosive, and abrasive media. The valves have a minimized pressure drop in the fully open position, they are easy to actuate, they have a relatively low weight, and are cost-effective.

How does a Knife Gate Valve work?

A knife gate valve works by allowing thick media to easily flow over soft seals with no interference. They work by chopping up the media as it passes through the valve. Today knife gate valves are used in numerous processing plants all over the world and come in large sizes. This makes it easier for the valve to handle thick flows of media including grease, oils, slurry, waste water, and paper pulp. Due to this, knife gate valves have low-pressure limitations and are designed to seat the blade into a soft seal with no disruption.

The gate of the knife gate valve can complete its work and make up for the deviation of sealing surface angle in the process of processing. This gate is called the elastic gate. Only when the knife gate valve is closed, the sealing surface can be sealed only by medium pressure. And most knife gate valves adopt a forced seal, that is, when the valve is closed, the gate must be forced to the valve seat by an external force, so as to make all knife gate valves better used.

What is a Knife Gate Valve used for?

Knife gate valve is mainly used in natural gas, petroleum, chemical industry, environmental protection, urban pipeline, gas pipeline and other transmission pipelines, vent system, and steam storage device, and the improved products will be more widely used.

- Mining and minerals processing

- Pulp and paper applications

- Water & Wastewater

- Sand and gravel plants

- Tailing lines

- Abrasive slurry materials

Advantages of Knife Gate Valves

- Gland box packing and machined support

- Easy maneuvering and low energy consumption

- Low maintenance through gate guidance via stable top works

- Unique seat design and seat material for high performance and low LCC

- No flow restriction fully open

- One piece casting body

- Stainless steel gate

- Robust gland box packing system

Knife Gate Valve Application

Knife gate valves are typically found in wastewater treatment plants, chemical plants, mining, cement plants as well as in many other industrial applications while gate valves are typically found in drinking water mains, distribution networks, and drinking water pump stations.

What is a Slab Gate Valve?

Slab through conduit gate valves are designed and manufactured in accordance with API 6D and API 6A standards and specifically for on-off services. This valve is suited to withstand all types of process fluids, under high pressure and temperature conditions.

The valve design includes a rising stem that accommodates the upward and downward movements of the gate allowing it to open and close under the line pressure.

How does a Slab Gate Valve work?

In normal operation, line fluid fills the cavity and the gate is lifted by the pressure generated from the flow path assisting the actuator spring to open the valve, resulting in a fail-open configuration.

Slab through conduit gate valves are piggable in the fully open position and generate pressure drop across the valve equal to the inside diameter of the connecting pipe.

Advantages of Slab Gate Valves?

- Double block and bleed seat design;

- Operating torque is smaller than the normal gate valve;

- Bidirectional seals, no limitation on the flow direction;

- When the valve is in the fully open position, seat surfaces are outside the flow stream that is always in full contact with a gate that can protect seat surfaces, and is suitable for the pigging pipeline;

- Non-rising stem design can be chosen;

- Spring-loaded packing can be chosen;

- Low emission packing can be chosen according to ISO 15848 requirements;

- Stem extended design can be chosen;

- Normally open type or normally close type with through conduit design;

- Non-through conduit design is also available as per customer request

As for proper material selection, those with strict testing, light operation, and strong corrosion resistance can meet everyone’s needs.

Slab Gate Valve Application

This slab gate valve is through conduit, piggable, and top entry. Applications include transportation pipelines for gas, crude oil, and oil products. Available in a variety of materials and configurations to meet your specific project requirements. and low operating torque.

Knife Valve vs Gate Valve

The differences between them are vast. First off, yes, the knife gate valve has a sharpened disk. This is meant to sever any stringent solids that may keep the valve from closing and causing it to leak. But there’s more that makes their designs quite different.

Different Design Standard

The biggest difference between these two types of valves is that gate valves are built to ANSI standards while knife gate valves adhere to TAPPI standards. Therefore, dimensionally the gate valve is wider, flanged, and ANSI pressure rated. It also has API leak tightness standards that must be met. They’re bi-directional and commonly used in steam applications as well as fluid applications. The gate valve is only available with metal seats.

Another significant difference between an ANSI gate valve and a knife gate valve is in the packing gland area. A gate valve will have a v-ring packing set that seals the shaft attached to the gate, while a knife gate valve has a packing gland that seals around the gate.

Different End Type

A knife gate has a very thin profile compared to its bulkier counterpart. It’s also uni-directional (though bi-directional is an option on some), and comes in either wafer or lugged body, with no flanges.

Different Seat Structure

The seats on the knife gate valve come in everything from metal to resilient types. The knife gate valve has a knife-shaped oblique cut at the bottom of the valve plate, which has the function of cutting off the medium so that the valve is closed without being blocked by the medium.

Different Function

The function of the knife gate valve is that it can only be used as a cut-off function and cannot be used as a throttling.

The gate valve can be used for throttling or as a switch.

Different Installation, Operation & Application

Compared with ordinary gate valves, knife gate valves are simple in structure, small in size, flexible in operation, easy to install, and suitable for medium with higher consistency and solid particles.

The full-bore knife gate valve design allows the valve to be used under dirty conditions, and the replaceable seat and packing make the valve easy to maintain.

Because of its better performance, the price of knife gate valves is generally higher than that of gate valves.

Gate Valve Application

Gate valves are used in many industrial applications including the oil and gas industry, pharmaceuticals, manufacturing, automotive, and marine. Non-rising stem gate valves are very popular on ships, in underground applications, or where vertical space is limited because they don’t take up extra space.

Related Tags :

ZECO Valve

Shanghai Pressure Reducing Valve Factory

Gate Valve Repair

Gate Valve vs Ball Valve

What is a Globe Valve?

Difference Between Gate Valve And Butterfly Valve

Globe Valve vs Ball Valve

Related Tags :

ZECO Valve

Gate Valve vs Ball Valve

NBR Butterfly Valve

What is an Axial Check Valve

Gate Valve Repair

What is a Globe Valve?

Manual Operate Gate Valve Manufacturer

What are Globe Valves?

Difference Between Gate Valve And Butterfly Valve