Globe Valve Vs Gate Valve

The Application of Globe Valve Vs Gate Valve

Introducing Rotork Globe Valve Vs Gate Valve, two essential components in fluid control systems. While globe valves are versatile and effective in regulating flow, particularly in smaller sizes like 1/2 globe valve, gate valves excel in larger applications, such as 12-inch gate valve. Rotork offers both options, ensuring suitability for various industrial needs. Globe valves are known for precise flow control, ideal for throttling applications. In contrast, gate valves provide on/off control with minimal pressure drop. Each has distinct advantages based on specific system requirements, with Rotork providing reliable solutions for fluid control challenges.

What Is Globe Valve Vs Gate Valve?

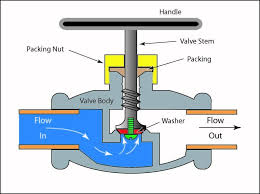

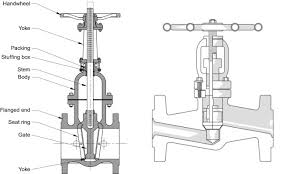

A Globe Valve is a type of valve that controls flow by moving a plug or disc up and down against the flow path. In contrast, a Gate Valve controls flow by raising or lowering a gate to open or close the flow path.

How Does Globe Valve Vs Gate Valve work?

A Globe Valve controls flow by moving a plug or disc up and down against the flow path. On the other hand, a Gate Valve controls flow by raising or lowering a gate to open or close the flow path.

Features of Globe Valve Vs Gate Valve

- Flow Control: Globe valves offer precise flow control due to their design, making them suitable for throttling applications. In contrast, gate valves provide excellent on/off control with minimal pressure drop.

- Size Range: Globe valves are commonly available in smaller sizes, such as 1/2 globe valve, while gate valves are preferred for larger sizes, including gate valve 12 inch.

- Design: Globe valves have a more complex design with a plug or disc mechanism, while gate valves have a simpler design with a gate that moves perpendicular to the flow direction.

- Pressure Drop: Globe valves typically have a higher pressure drop compared to gate valves, making gate valves more suitable for high-pressure applications.

- Application: Globe valves are commonly used in industries requiring precise flow control, such as HVAC systems and water treatment plants. Gate valves are often used in applications where the flow needs to be completely shut off or fully open, such as in pipelines and large industrial processes.

Advantages of Globe Valve Vs Gate Valve

- Globe Valve Advantages:

- Precise Flow Control: Globe valves offer precise regulation of flow, making them suitable for applications requiring accurate adjustments.

- Versatility: They can handle a wide range of temperatures and pressures, making them suitable for various industrial applications.

- Good Sealing: Globe valves provide reliable sealing, reducing the risk of leakage even in high-pressure environments.

- Gate Valve Advantages:

- Minimal Pressure Drop: Gate valves offer minimal resistance to flow when fully open, resulting in minimal pressure drop across the valve.

- Full Flow Opening: Gate valves provide a full flow opening, allowing for unobstructed flow when fully open.

- Durability: They are robust and suitable for handling high-pressure and high-temperature applications, ensuring long-term reliability.

The Specifications of Globe Valve Vs Gate Valve

| Specification | Globe Valve | Gate Valve |

|---|---|---|

| Type | Globe Valve | Gate Valve |

| Ball Material | N/A | N/A |

| Attachment Type | Threaded, Flanged, Socket Weld, Butt Weld | Flanged, Threaded, Socket Weld |

| Thread Standard | ANSI/ASME B1.20.1, ISO 7/1 | ANSI/ASME B1.20.1, ISO 7/1 |

| Thread Size | Various sizes available | Various sizes available |

| Body Material | Cast Iron, Ductile Iron, Carbon Steel, Stainless Steel | Cast Iron, Ductile Iron, Carbon Steel, Stainless Steel |

| Safe for Use With | Water, Steam, Oil, Gas, Various Chemicals | Water, Steam, Oil, Gas, Various Chemicals |

| Handle Type | Handwheel, Lever | Handwheel, Lever |

| Handle Material | Cast Iron, Ductile Iron, Stainless Steel, Carbon Steel | Cast Iron, Ductile Iron, Stainless Steel, Carbon Steel |

| Maximum Working Pressure | Up to 2500 psi (172 bar) | Up to 6000 psi (414 bar) |

| Operating Pressure | Dependent on system settings | Dependent on system settings |

The Parameter of Globe Valve Vs Gate Valve

- Type: Globe Valve and Gate Valve are two different types of valves commonly used in industrial applications.

- Ball Material: The material used for the ball component varies depending on the specific design and application requirements.

- Attachment Type: Both valves can be attached using threaded, flanged, socket weld, or butt weld connections.

- Thread Standard: They adhere to industry-standard thread specifications such as ANSI/ASME B1.20.1 and ISO 7/1.

- Thread Size: Various sizes are available for both Globe Valve and Gate Valve to accommodate different pipeline requirements.

- Body Material: The body of these valves can be constructed from materials like cast iron, ductile iron, carbon steel, or stainless steel.

- Safe for Use With: Both valves are suitable for use with water, steam, oil, gas, and various chemicals depending on the material compatibility.

- Handle Type: They can feature handwheel or lever handles for manual operation.

- Handle Material: Handles can be made from materials such as cast iron, ductile iron, stainless steel, or carbon steel.

- Maximum Working Pressure: The maximum working pressure for Globe Valve and Gate Valve depends on their design and construction, with values typically ranging up to 2500 psi (172 bar) and 6000 psi (414 bar) respectively.

- Operating Pressure: The operating pressure of these valves is determined by the specific requirements of the system in which they are installed.

The Operation Theory of Globe Valve Vs Gate Valve

The operation theory of a Globe Valve involves controlling flow by moving a plug or disc up and down against the flow path, offering precise regulation suitable for 1/2 globe valve applications. In contrast, a Gate Valve operates by raising or lowering a gate to open or close the flow path, often requiring gate valve stem replacement for maintenance. Globe valves excel in throttling applications, providing accurate flow control, while gate valves are preferred for their full flow opening and minimal pressure drop, making them ideal for on/off control in various industrial settings.

The Parameters Table of Globe Valve Vs Gate Valve

| Parameter | Globe Valve | Gate Valve |

|---|---|---|

| Type | Globe Valve | Gate Valve |

| Ball Material | N/A | N/A |

| Attachment Type | Threaded, Flanged, Socket Weld, Butt Weld | Flanged, Threaded, Socket Weld, Butt Weld |

| Thread Standard | ANSI/ASME B1.20.1, ISO 7/1 | ANSI/ASME B1.20.1, ISO 7/1 |

| Thread Size | Various sizes available | Various sizes available |

| Body Material | Cast Iron, Ductile Iron, Carbon Steel, Stainless Steel | Cast Iron, Ductile Iron, Carbon Steel, Stainless Steel |

| Seat Material | Stainless Steel, Brass, Bronze, Soft Seat, Hard Seat | Stainless Steel, Brass, Bronze, Soft Seat, Hard Seat |

| Stem Material | Stainless Steel, Brass, Bronze | Stainless Steel, Brass, Bronze |

| Bonnet Material | Cast Iron, Ductile Iron, Carbon Steel, Stainless Steel | Cast Iron, Ductile Iron, Carbon Steel, Stainless Steel |

| Disc Material | Stainless Steel, Brass, Bronze | Stainless Steel, Brass, Bronze |

| Maximum Working Pressure | Up to 2500 psi (172 bar) | Up to 6000 psi (414 bar) |

| Operating Pressure | Dependent on system settings | Dependent on system settings |