Sluice Gates

The Application of Sluice Gates

Introducing Rotork Sluice Gates, essential for fluid control in various applications. Sluice gates, also known as sluice valves or sluice gate valves, regulate water flow in channels, canals, and dams. Designed for durability and reliability, Rotork’s sluice gates ensure efficient water management, flood control, and irrigation systems. These gates offer precise flow control, allowing operators to manage water levels effectively. With Rotork’s expertise in fluid control solutions, our sluice gates provide dependable performance and contribute to sustainable water resource management worldwide.

What Is Sluice Gates?

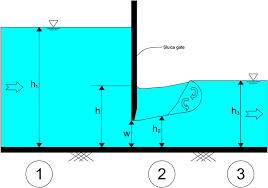

Sluice gates are hydraulic control structures used to regulate water flow in channels, canals, and dams, facilitating flood control, irrigation, and water management.

How Does Sluice Gates work?

Sluice gates work by controlling the flow of water through a channel or canal. They can be raised or lowered to adjust the water level, allowing operators to manage the flow according to specific needs such as flood control, irrigation, or water supply.

Features of Sluice Gates

- Versatility: Sluice gates are versatile and can be used in various applications such as flood control, irrigation, and wastewater management.

- Adjustability: They offer adjustable flow control, allowing operators to regulate water levels and flow rates as needed.

- Durability: Constructed from robust materials like steel, aluminum, or concrete, sluice gates are durable and can withstand harsh environmental conditions.

- Customization: Sluice gates can be customized to fit specific requirements, including size, shape, and operating mechanism, ensuring suitability for different projects.

- Automation: Some sluice gates can be equipped with automation systems for remote operation, enhancing efficiency and convenience.

- Sealing: They feature effective sealing mechanisms to prevent water leakage when closed, ensuring efficient flow control.

- Safety: Sluice gates are designed with safety features to prevent accidents and ensure reliable operation, even in challenging conditions.

Advantages of Sluice Gates

- Effective Flow Regulation: Sluice gates offer precise control over water flow, allowing for efficient management of water levels and flow rates.

- Versatility: They can be used in a variety of applications, including flood control, irrigation, and wastewater management, making them highly versatile.

- Durability: Constructed from sturdy materials such as steel, aluminum, or concrete, sluice gates are durable and can withstand harsh environmental conditions.

- Customization: Sluice gates can be customized to fit specific project requirements, including size, shape, and operating mechanism, ensuring optimal performance.

- Cost-Effectiveness: Compared to other flow control methods, sluice gates often provide a cost-effective solution for water management needs.

- Reliability: With proper maintenance, sluice gates can provide reliable long-term performance, contributing to effective water resource management.

The Specifications of Sluice Gates

| Specification | Details |

|---|---|

| Type | Sluice Gate |

| Ball Material | N/A |

| Attachment Type | Hinge, Flange, Mounting Bracket |

| Thread Standard | N/A |

| Thread Size | N/A |

| Body Material | Steel, Aluminum, Concrete |

| Safe for Use With | Water, Wastewater, Various Liquids |

| Handle Type | Handwheel, Gear Mechanism, Hydraulic Actuator |

| Handle Material | Steel, Aluminum, Plastic |

| Maximum Working Pressure | Dependent on Design and Application |

| Maximum Working Pressure | Dependent on Design and Application |

| Operating Pressure | Dependent on Design and Application |

The Parameter of Sluice Gates

- Type: Sluice gates are specifically designed for controlling the flow of water in channels, canals, and dams.

- Body Material: Typically constructed from durable materials such as steel, aluminum, or concrete, ensuring longevity and resistance to environmental conditions.

- Attachment Type: Available with various attachment options including hinges, flanges, and mounting brackets for secure installation.

- Handle Type: Equipped with different handle types such as handwheels, gear mechanisms, or hydraulic actuators for manual or automated operation.

- Safe for Use With: Suitable for use with water, wastewater, and various liquids commonly encountered in water management systems.

- Maximum Working Pressure: The maximum pressure that sluice gates can withstand varies depending on their design and application requirements.

- Operating Pressure: The operating pressure of sluice gates is determined by the specific conditions and requirements of the system in which they are installed.

The Operation Theory of Sluice Gates

The operation theory of Sluice Gates, also known as sleuth gate, involves controlling the flow of water by raising or lowering a gate to regulate the water level. **Slide gates** are similar to sluice gates but operate horizontally rather than vertically. Sluice gates are commonly used in irrigation systems, dams, and water treatment plants to manage water flow and prevent flooding. The design and mechanism of sluice gates allow for efficient and precise control of water levels, making them essential components in water management infrastructure.

The Parameters Table of Sluice Gates

| Part | Material |

|---|---|

| Gate | Stainless Steel, Cast Iron, Aluminum, or Composite Materials |

| Frame | Steel, Cast Iron, or Concrete |

| Seals | Rubber or Synthetic Material |

| Operating Mechanism | Steel, Stainless Steel, or Aluminum Alloy |

| Guides | Stainless Steel, Bronze, or UHMWPE (Ultra-High Molecular Weight Polyethylene) |

| Lifting Mechanism | Steel, Stainless Steel, or Aluminum Alloy |

| Foundation | Concrete or Reinforced Concrete |

| Control System | Hydraulic, Pneumatic, Electric, or Manual |