Wafer Vs Lug Style Butterfly Valve

The Application of Wafer Vs Lug Style Butterfly Valve

Introducing Rotork Wafer Vs Lug Style Butterfly Valve, a leading choice in the realm of flow control solutions. When comparing lug vs wafer butterfly valve, each style offers distinct advantages. Lug butterfly valve designs feature bolt holes for installation, providing secure attachment and easy maintenance. Conversely, wafer vs lug butterfly valve design offers a more compact profile, ideal for space-constrained applications. Rotork’s expertise ensures both styles deliver reliable performance across various industries. Whether it’s for HVAC systems, water treatment plants, or industrial processes, Rotork Wafer Vs Lug Style Butterfly Valve provides efficient flow regulation and dependable operation.

What Is Wafer Vs Lug Style Butterfly Valve?

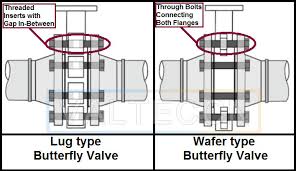

A Wafer Vs Lug Style Butterfly Valve refers to two different designs for butterfly valves. The wafer style is compact and fits between flanges, while the lug style has bolt holes for installation. Both have distinct advantages, catering to different application requirements and installation preferences in various industries.

How Does Wafer Vs Lug Style Butterfly Valve work?

The operation of a Wafer Vs Lug Style Butterfly Valve is quite similar. When the valve is open, the disc rotates perpendicular to the flow, allowing fluid to pass through. When closed, the disc rotates parallel to the flow, blocking it. The key difference lies in their installation methods: the wafer style fits between flanges, while the lug style has bolt holes for secure attachment.

Features of Wafer Vs Lug Style Butterfly Valve

- Installation: The wafer style is compact and fits between flanges, reducing space requirements and facilitating easier installation. In contrast, the lug style has bolt holes for secure attachment, ensuring stability and preventing movement during operation.

- Maintenance: Both styles offer easy maintenance, with the wafer style allowing for quick removal and replacement without disturbing the pipeline, while the lug style’s bolted design facilitates straightforward disassembly for maintenance or repairs.

- Versatility: Wafer style butterfly valves are versatile and suitable for a wide range of applications due to their compact design, while lug style valves are preferred for applications requiring higher pressure or where the valve needs to be securely anchored.

- Cost-effectiveness: Wafer style butterfly valves are often more cost-effective due to their simpler design and ease of installation, making them a popular choice for projects with budget constraints. Conversely, lug style valves offer added security and stability, making them suitable for critical applications.

Advantages of Wafer Vs Lug Style Butterfly Valve

- Wafer Style:

- Space-saving design: Fits between flanges, minimizing space requirements and reducing overall footprint.

- Cost-effective: Typically more economical due to simpler construction and easier installation process.

- Easy installation: Can be installed quickly and easily without the need for additional mounting hardware.

- Lightweight: Constructed with lightweight materials, making handling and transportation more manageable.

- Lug Style:

- Secure installation: Features bolt holes for secure attachment, preventing movement or dislodgement during operation.

- Enhanced stability: Ideal for applications requiring high-pressure conditions or where additional security is necessary.

- Versatility: Suitable for a wide range of applications, from low to high-pressure systems, offering flexibility in usage.

- Durable construction: Typically built with robust materials, ensuring longevity and reliability in demanding environments.

The Specifications of Wafer Vs Lug Style Butterfly Valve

Sure, here is the information you requested presented in a table format:

| Specifications | Details |

|---|---|

| Type | Cooling Tower Isolation Valve |

| Ball Material | Stainless Steel |

| Attachment Type | Threaded |

| Thread Standard | NPT (National Pipe Thread) |

| Thread Size | 1 inch |

| Body Material | Brass |

| Safe for Use With | Water, Coolants |

| Handle Type | Lever |

| Handle Material | Aluminum |

| Maximum Working Pressure | 150 psi |

| Maximum Working Pressure | 10.3 bar |

| Operating Pressure | 0-100 psi |

The Parameter of Wafer Vs Lug Style Butterfly Valve

- Type: Wafer Vs Lug Style Butterfly Valve

- Size Range: Available in various sizes to fit different piping systems.

- Mounting: Wafer valves are sandwiched between flanges, while lug valves have threaded inserts for easy installation.

- Pressure Rating: Both types can handle different pressure ratings based on design and material.

- Installation: Wafer valves are lighter and more compact, suitable for space-constrained applications, while lug valves provide added stability and can be installed without disconnecting the piping system.

- Sealing: Both valves offer effective sealing to prevent leakage and ensure efficient flow control.

- Applications: Wafer valves are commonly used in HVAC, water treatment, and general industrial applications, while lug valves are preferred in high-pressure and critical processes.

- Maintenance: Both types are designed for easy maintenance and repair, ensuring minimal downtime in operations.

- Material: Constructed from durable materials such as stainless steel, carbon steel, or ductile iron based on application requirements.

The Operation Theory of Wafer Vs Lug Style Butterfly Valve

- Butterfly Wafer Valve Operation: Butterfly wafer valves operate by a quarter-turn motion of the disc to control the flow of fluids in a pipeline. When the disc is turned perpendicular to the flow direction, it blocks the flow, and when parallel, it allows full flow.

- PVC Butterfly Valves: PVC butterfly valves operate similarly to other butterfly valves but are made from PVC material, offering corrosion resistance and suitability for various non-industrial applications.

- Butterfly Lug Style Valve Operation: Lug style butterfly valves have lugs (protrusions) on the valve body for installation. They operate in the same manner as wafer valves but provide additional support and stability due to the lugs during installation and operation.

The Parameters Table of Wafer Vs Lug Style Butterfly Valve

| Parameters | Wafer Style Butterfly Valve | Lug Style Butterfly Valve |

|---|---|---|

| Type | Wafer | Lug |

| Size Range | Various sizes available | Various sizes available |

| Mounting | Sandwiched between flanges | Lugs for installation |

| Pressure Rating | Depends on design and material | Depends on design and material |

| Installation | Lightweight and compact | Threaded inserts for stability during install |

| Sealing | Effective sealing to prevent leakage | Effective sealing to prevent leakage |

| Applications | Common in HVAC, water treatment, industries | Preferred in high-pressure and critical processes |

| Maintenance | Designed for easy maintenance and repair | Designed for easy maintenance and repair |

| Material | Stainless steel, carbon steel, ductile iron | Stainless steel, carbon steel, ductile iron |