Butterfly Valve Wafer Vs Lug

The Application of Butterfly Valve Wafer Vs Lug

When it comes to lug vs wafer butterfly valve options, the choice often depends on the application requirements. Lug butterfly valves provide added stability with their lugs, making them suitable for high-pressure systems. On the other hand, CPVC butterfly valves offer corrosion resistance and are ideal for non-industrial applications. For reliable performance, consider the Rotork Wafer Vs Lug Style Butterfly Valve, known for its quality and precision. Whether it’s HVAC, water treatment, or industrial processes, selecting the right valve type—be it lug or wafer—ensures efficient flow control and seamless operation in various applications.

What Is Wafer Vs Lug Style Butterfly Valve?

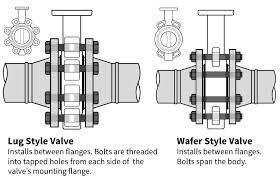

Wafer vs Lug style butterfly valve refers to two common designs for butterfly valves. Wafer valves are sandwiched between flanges, while lug valves have protruding lugs for installation. The choice between the two depends on factors like space constraints, installation ease, and system pressure requirements. Both types effectively control flow and offer reliable sealing, making them versatile choices for various applications.

How Does Wafer Vs Lug Style Butterfly Valve work?

Wafer and Lug style butterfly valves work by rotating a disc to control the flow of fluids in a pipeline. When the disc is turned perpendicular to the flow direction, it blocks the flow, and when parallel, it allows full flow. Wafer valves are sandwiched between flanges, while lug valves have lugs for installation, providing stability and support during operation.

Features of Wafer Vs Lug Style Butterfly Valve

- Design

- Wafer Valve: Thin and lightweight design for easy installation between flanges.

- Lug Valve: Features lugs for secure installation without needing to disconnect the piping system.

- Mounting

- Wafer Valve: Mounted between flanges using bolts.

- Lug Valve: Lugs provide additional stability during installation and operation.

- Applications

- Wafer Valve: Suitable for HVAC, water treatment, and general industrial applications.

- Lug Valve: Ideal for high-pressure and critical processes where stability is crucial.

- Sealing

- Both: Offer effective sealing to prevent leakage and ensure precise flow control.

- Material

- Both: Constructed from durable materials like stainless steel or ductile iron for longevity and reliability.

Advantages of Wafer Vs Lug Style Butterfly Valve

- Wafer Style Butterfly Valve

- Easy to install between flanges, saving time and effort.

- Compact design saves space in the piping system.

- Suitable for applications with limited space constraints.

- Lug Style Butterfly Valve

- Provides added stability and support during installation.

- Can be installed without disconnecting the piping system.

- Ideal for high-pressure applications where secure mounting is essential.

The Specifications of Wafer Vs Lug Style Butterfly Valve

| Specifications | Details |

|---|---|

| Type | Butterfly Valve |

| Ball Material | Stainless Steel |

| Attachment Type | Lug |

| Thread Standard | N/A |

| Thread Size | N/A |

| Body Material | Carbon Steel |

| Safe for Use With | Water, Air, Neutral Gases |

| Handle Type | Lever |

| Handle Material | Steel |

| Maximum Working Pressure (psi) | 150 |

| Maximum Working Pressure (bar) | 10.3 |

| Operating Pressure | 0-100 psi |

The Parameter of Wafer Vs Lug Style Butterfly Valve

- Wafer Style Butterfly Valve Parameters

- Lightweight and compact design for easy installation between flanges.

- Suitable for applications with space constraints.

- Effective sealing to prevent leakage and ensure precise flow control.

- Lug Style Butterfly Valve Parameters

- Features lugs for secure installation without disconnecting the piping system.

- Provides additional stability and support during operation.

- Ideal for high-pressure and critical processes where stability is crucial.

The Operation Theory of Wafer Vs Lug Style Butterfly Valve

The operation theory of butterfly wafer valve and industrial butterfly valve involves a disc that rotates within the pipeline to control the flow of fluids. In a wafer valve, the disc is positioned between flanges and rotates to either block or allow flow. Lug valves feature lugs for installation and provide stability during operation. When the disc is parallel to the flow direction, it allows full flow, while being perpendicular blocks the flow. This simple yet effective design makes both wafer and lug style butterfly valves popular choices for industrial applications where precise flow control is essential.

The Parameters Table of Wafer Vs Lug Style Butterfly Valve

| Parameters | Wafer Style Butterfly Valve | Lug Style Butterfly Valve |

|---|---|---|

| Type | Butterfly Valve | Butterfly Valve |

| Body Material | Stainless Steel | Ductile Iron |

| Attachment Type | Wafer | Lug |

| Seal Material | EPDM, PTFE, Viton | Buna-N, EPDM |

| Maximum Working Pressure | 150 psi | 200 psi |

| Operating Temperature | -20°C to 120°C | -10°C to 150°C |

| End Connection | Flanged | Flanged, Lug |

| Actuator Type | Manual, Pneumatic, Electric | Manual, Gear, Actuated |

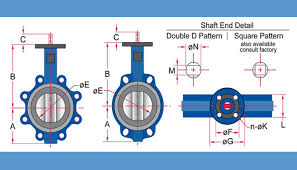

| Size Range | 2″ to 24″ | 2″ to 12″ |