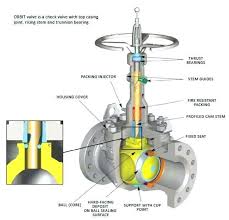

Orbit Valve Parts Diagram

The Application of Orbit Valve

Introducing Rotork Orbit Valve, a leading name in fluid control technology. Engineered for excellence, the Orbit Valve boasts innovative features designed to tackle diverse applications. Its precision-engineered design, exemplified by the orbit valve diagram, ensures optimal performance and reliability.

In demanding environments such as boiler blowdown systems, the Orbit Valve excels, offering precise control over fluid flow while minimizing the risk of leakage. With its robust construction and advanced sealing technology, concerns about orbit valve leaking become a thing of the past.

The Rotork Orbit Valve sets the standard for efficiency and durability, making it the preferred choice for industries worldwide. Experience unmatched performance and peace of mind with the Rotork Orbit Valve.

What Is Orbit Valve?

The Orbit Valve is a high-performance component used in fluid control systems. Known for its reliability and precision, this valve efficiently regulates the flow of liquids or gases in industrial applications. Its innovative design and advanced features make it a preferred choice for engineers seeking optimal performance and durability in fluid management.

How Does Orbit Valve work?

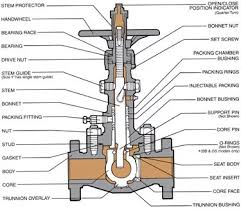

The Orbit Valve operates by controlling the flow of fluids through a system. Utilizing its internal mechanisms, such as a ball or disc, it modulates the flow rate, direction, or pressure according to user input. Through precise engineering and construction, the valve ensures efficient and reliable fluid control in various industrial processes.

Features of Orbit Valve

- Robust Construction: Orbit Valves are built with durable materials to withstand harsh operating conditions, ensuring long-term reliability.

- Precision Control: Equipped with advanced mechanisms, these valves offer precise regulation of fluid flow, providing accurate control over flow rates, pressure, and direction.

- Leakage Prevention: Featuring tight sealing technology, Orbit Valves minimize the risk of leaks, enhancing overall system efficiency and preventing fluid wastage.

- Versatility: Available in various types and sizes, Orbit Valves cater to diverse application requirements, providing flexibility in fluid control solutions.

- Ease of Maintenance: Designed for easy access to internal components, Orbit Valves facilitate quick servicing and maintenance, minimizing downtime and operational costs.

- Compatibility: Suitable for a wide range of fluids and operating conditions, Orbit Valves offer compatibility with different media and environments.

- Reliability: With their robust construction and precise engineering, Orbit Valves deliver consistent and reliable performance, ensuring smooth operation in critical applications.

Advantages of Orbit Valve

- Efficient Fluid Control: Orbit Valves provide precise regulation of fluid flow, enabling efficient operation and optimization of system performance.

- Reliable Sealing: With advanced sealing technology, these valves minimize the risk of leaks, ensuring system integrity and preventing fluid wastage.

- Durable Construction: Constructed from high-quality materials, Orbit Valves offer durability and longevity, reducing the need for frequent replacements and maintenance.

- Versatile Application: Suitable for a wide range of industries and applications, Orbit Valves offer versatility in fluid control solutions, catering to diverse needs.

- Ease of Installation: Featuring user-friendly designs and standardized fittings, Orbit Valves are easy to install and integrate into existing systems, reducing installation time and costs.

- Precise Operation: Equipped with precision-engineered components, Orbit Valves deliver accurate and reliable performance, allowing for precise control over fluid flow, pressure, and direction.

The Specifications of Orbit Valve

| Specification | Details |

|---|---|

| Type | Ball valve, globe valve, butterfly valve, etc. |

| Ball Material | Stainless steel, brass, or other corrosion-resistant material |

| Attachment Type | Flanged, threaded, welded, or compression fittings |

| Thread Standard | ANSI, BSPP, NPT, or DIN standards |

| Thread Size | Varies depending on valve size and type |

| Body Material | Stainless steel, brass, or other durable material |

| Safe for Use With | Water, air, oil, gas, or other compatible fluids |

| Handle Type | Lever, handwheel, actuator, or other control mechanisms |

| Handle Material | Steel, aluminum, or other durable material |

| Maximum Working Pressure (psi) | Varies depending on valve type, size, and material |

| Maximum Working Pressure (bar) | Varies depending on valve type, size, and material |

| Operating Pressure | Varies depending on system requirements and valve specifications |

The Parameter of Orbit Valve

- Type: The Orbit Valve comes in various types, including ball valves, globe valves, butterfly valves, etc., each serving different purposes within fluid control systems.

- Ball Material: Typically constructed from stainless steel, brass, or other corrosion-resistant materials to ensure durability and longevity.

- Attachment Type: Available with various attachment types such as flanged, threaded, welded, or compression fittings, allowing for versatile installation options.

- Thread Standard: Adheres to industry standards such as ANSI, BSPP, NPT, or DIN, ensuring compatibility with other system components.

- Thread Size: Varies depending on valve size and type, accommodating different system requirements and flow rates.

- Body Material: Constructed from stainless steel, brass, or other durable materials to withstand the rigors of fluid control applications.

- Safe for Use With: Designed to handle water, air, oil, gas, or other compatible fluids commonly used in industrial processes.

- Handle Type: Equipped with levers, handwheels, actuators, or other control mechanisms for manual or automated operation, providing flexibility in control.

- Handle Material: Made from steel, aluminum, or other sturdy materials to ensure smooth and reliable operation.

- Maximum Working Pressure (psi): Capable of withstanding pressures ranging from a few psi to several thousand psi, depending on the valve type, size, and material.

- Maximum Working Pressure (bar): Able to handle pressures ranging from a few bar to several tens of bar, depending on the valve type, size, and material.

- Operating Pressure: Operating pressure varies based on system requirements and valve specifications, ensuring optimal performance and efficiency.

The Operation Theory of Orbit Valve

- Flow Regulation: The valve modulates the flow of fluids through the system, allowing for precise control over flow rates, pressure, and direction.

- Internal Mechanisms: Depending on the type of valve, the Orbit Valve may employ a ball, disc, or other internal mechanism to adjust flow conditions.

- Sealing Technology: Utilizing advanced sealing technology, the valve maintains tight seals to prevent leaks and ensure system integrity.

- Control Mechanisms: Equipped with levers, handwheels, or actuators, the valve enables manual or automated control, providing flexibility in operation.

- Fluid Compatibility: Designed to handle a wide range of fluids, including water, air, oil, and gas, the excellent orbit valve offers versatility in application.

- Reliability: With its robust construction and precise engineering, the Orbit Valve delivers consistent and reliable performance, even in demanding environments.

The Parameters Table of Orbit Valve

| Parameter | Details |

|---|---|

| Type | Ball valve, globe valve, butterfly valve, etc. |

| Ball Material | Stainless steel, brass, or other corrosion-resistant material |

| Stem Material | Stainless steel or other durable material |

| Body Material | Stainless steel, brass, or other durable material |

| Seat Material | PTFE, EPDM, or other resilient material |

| Seal Material | PTFE, EPDM, or other resilient material |

| Handle Material | Steel, aluminum, or other durable material |

| Attachment Type | Flanged, threaded, welded, or compression fittings |

| Maximum Working Pressure (psi) | Varies depending on valve type, size, and material |

| Maximum Working Pressure (bar) | Varies depending on valve type, size, and material |

| Operating Pressure | Varies based on system requirements and valve specifications |