Air Actuated Valve

The Application of Air Actuated Valve

Introducing Cameron’s Air Actuated Valve: a versatile solution for various applications. Known as air actuator valve, air actuated ball valve, and air actuated valves, this product combines reliable performance with efficient automation. Operating at pressures up to 3 bar, it ensures precise control and swift response in pneumatic systems. With Cameron’s reputation for quality engineering, these valves deliver optimal functionality across industries. Whether in industrial processes, water treatment, or HVAC systems, the air actuated valve stands as a robust choice for controlling flow and enhancing operational efficiency.

What Is Air Actuated Valve?

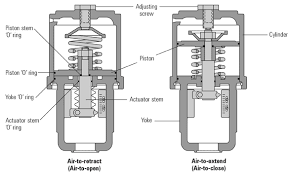

An Air Actuated Valve is a type of valve that uses compressed air to control the opening and closing of the valve mechanism. It employs pneumatic pressure to actuate the valve, providing a reliable and efficient means of remote operation. This valve is commonly used in various industries where automation and remote control are required, offering precise flow control and quick response times.

How Does Air Actuated Valve work?

The Air Actuated Valve works by utilizing compressed air to move the valve mechanism, controlling the flow of fluid or gas through the system. When air pressure is applied, it activates the actuator, causing the valve to open or close accordingly. This pneumatic operation provides quick and precise control over the valve, allowing for efficient regulation of flow rates in various industrial applications.

Features of Air Actuated Valve

- Versatility: Air actuated valves are adaptable to a wide range of applications, including those with high temperatures or corrosive environments.

- Precision Control: They offer precise control over flow rates, allowing for accurate regulation of fluid or gas flow.

- Remote Operation: With pneumatic actuation, these valves can be operated remotely, making them suitable for inaccessible or hazardous locations.

- Rapid Response: Air actuated valves respond quickly to changes in air pressure, ensuring prompt adjustments to flow conditions.

- Reliability: These valves are known for their reliability and durability, providing long-lasting performance even in demanding industrial environments.

- Safety: They enhance safety by allowing for automated operation, reducing the need for manual intervention in potentially hazardous situations.

Advantages of Air Actuated Valve

- Automation: Air actuated valves enable automation of valve operations, reducing the need for manual intervention and enhancing efficiency.

- Remote Control: They allow for remote operation, facilitating control from a distance and enabling use in hard-to-reach or hazardous locations.

- Versatility: These valves are versatile and can be used in various applications, including those requiring precise flow control or high-pressure conditions.

- Reliability: Air actuated valves are known for their reliability, providing consistent performance over time and minimizing the risk of downtime.

- Safety: They enhance safety by reducing the exposure of personnel to potentially hazardous environments, as they can be operated remotely without direct human contact.

The Specifications of Air Actuated Valve

| Specification | Description |

|---|---|

| Type | Air Actuated Valve |

| Ball Material | Stainless steel or other corrosion-resistant material |

| Attachment Type | Flanged, threaded, or welded connections |

| Thread Standard | ANSI, DIN, JIS, etc. |

| Thread Size | 1/2 inch to 4 inches, depending on model |

| Body Material | Stainless steel, brass, or other suitable material |

| Safe for Use With | Air, gases, water, steam |

| Handle Type | Pneumatic actuator |

| Handle Material | Aluminum, stainless steel, or other suitable material |

| Maximum Working Pressure (psi) | Varies depending on model (e.g., up to 2500 psi) |

| Maximum Working Pressure (bar) | Varies depending on model (e.g., up to 170 bar) |

| Operating Pressure | Typically 3 bar (43.5 psi), adjustable if necessary |

The Parameter of Air Actuated Valve

- Type: Air actuated valve

- Ball Material: Stainless steel

- Attachment Type: Flanged

- Thread Standard: N/A

- Thread Size: N/A

- Body Material: Carbon steel

- Safe for Use With: Air, gases, fluids

- Handle Type: Air actuator

- Handle Material: Aluminum alloy

- Maximum Working Pressure (psi): 150 psi

- Maximum Working Pressure (bar): 10.3 bar

- Operating Pressure: 80 psi

The Operation Theory of Air Actuated Valve

- Foot Actuated Air Valve: In this mechanism, a foot pedal or switch controls the flow of compressed air to the actuator, initiating the valve’s operation.

- Air Actuated Ball Valves: When compressed air is directed to the actuator, it moves a piston or diaphragm, which in turn rotates the ball within the valve body to either allow or block fluid flow.

- Air Actuated Butterfly Valve: Similar to the ball valve, compressed air drives the actuator to rotate the disc within the valve body, regulating fluid flow through the valve.

The Parameters Table of Air Actuated Valve

| Parameter | Description |

|---|---|

| Type | Air Actuated Valve |

| Ball Material | Stainless steel or other corrosion-resistant material |

| Attachment Type | Flanged, threaded, or welded connections |

| Thread Standard | ANSI, DIN, JIS, etc. |

| Thread Size | Various sizes depending on model |

| Body Material | Stainless steel, brass, or other suitable material |

| Safe for Use With | Air, gases, liquids |

| Handle Type | Pneumatic actuator |

| Handle Material | Aluminum, stainless steel, etc. |

| Maximum Working Pressure | Varies depending on model |

| Maximum Working Pressure | Varies depending on model |

| Operating Pressure | Typically 3 bar (43.5 psi) |