Gate Valve Vs Globe Valve

The Application of Gate Valve Vs Globe Valve

Gate Valve and Globe Valve are two common types of valves used in various industries. Gate Valve features a parallel gate-like disc that moves up and down to control the flow of fluid. It is well-suited for applications requiring full flow or complete shut-off, such as in pipelines and large bore applications. On the other hand, Globe Valve has a spherical body and a movable plug that regulates flow by moving perpendicular to the flow direction. It is ideal for applications requiring fine flow control or throttling, like in water treatment plants and steam systems. Cameron, a renowned brand, offers a wide range of Gate and Globe Valves tailored to different industrial needs. Both types have their advantages and are selected based on specific operational requirements and fluid characteristics.

globe vs gate valve

globe valve vs gate valve

gate valve vs globe valve

gate vs globe valve

What Is Gate Valve and Globe Valve?

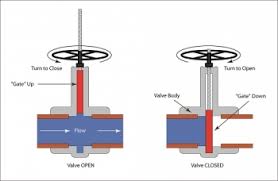

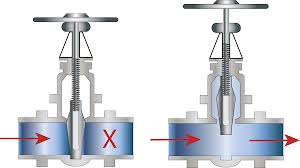

Gate Valve and Globe Valve are two types of valves used in various industries. The Gate Valve controls flow by raising or lowering a gate-like disc, while the Globe Valve regulates flow by moving a plug in a perpendicular direction.

How Does Gate Valve and Globe Valve work?

Gate Valves control flow by raising or lowering a gate to open or close the passage. Conversely, Globe Valves regulate flow by moving a plug against the flow direction to adjust the flow rate.

Features of Gate Valve and Globe Valve

- Gate Valve Features:

- Straight Through Flow: Gate valves offer minimal obstruction to fluid flow when fully open, allowing for efficient flow passage.

- Tight Seal: The gate mechanism ensures a tight seal against the valve seat, minimizing leakage when closed.

- On/Off Functionality: Gate valves provide reliable on/off control with minimal pressure drop across the valve.

- Suitable for High Pressure: They are commonly used in applications requiring high-pressure handling due to their robust construction.

- Less Flow Control: Gate valves are not ideal for precise flow control as they mainly serve as isolation valves.

- Globe Valve Features:

- Precise Flow Control: Globe valves offer excellent flow control capability, allowing for precise regulation of flow rate.

- Pressure Equalization: The globe valve design helps equalize pressure across the valve, reducing the risk of valve damage.

- Multi-Directional Flow: Globe valves can handle flow in both directions, providing versatility in piping systems.

- Good Shut-Off: They provide a reliable shut-off function, minimizing leakage even at high pressures.

- Compact Design: Globe valves often have a more compact design compared to gate valves, making them suitable for space-constrained installations.

Advantages of Gate Valve and Globe Valve

- Advantages of Gate Valve:

- Low Pressure Drop: Gate valves offer minimal resistance to fluid flow, resulting in lower pressure drop across the valve.

- High Pressure Handling: They are suitable for applications requiring high-pressure handling due to their robust construction.

- Reliable Sealing: Gate valves provide a tight seal when fully closed, minimizing the risk of leakage.

- On/Off Control: Gate valves offer reliable on/off control, making them suitable for isolation purposes in pipelines.

- Cost-Effective: Gate valves are often more cost-effective compared to globe valves, especially in large-diameter applications.

- Advantages of Globe Valve:

- Precise Flow Control: Globe valves offer excellent flow control capabilities, allowing for precise regulation of flow rate.

- Versatility: They can handle flow in both directions, providing versatility in piping systems.

- Good Shut-Off: Globe valves provide reliable shut-off functionality, even at high pressures, reducing the risk of leakage.

- Pressure Equalization: The design of globe valves helps equalize pressure across the valve, reducing the risk of damage.

- Suitability for Throttling: Globe valves are ideal for applications requiring throttling or fine flow control adjustments.

The Specifications of Gate Valve and Globe Valve

| Specification | Gate Valve | Globe Valve |

|---|---|---|

| Type | Rising Stem, OS & Y | Straight Pattern, Angle Pattern |

| Ball Material | Brass, Stainless Steel, Cast Iron | Brass, Stainless Steel, Cast Iron |

| Attachment Type | Flanged, Threaded, Welded | Flanged, Threaded, Welded |

| Thread Standard | ANSI, BS, DIN | ANSI, BS, DIN |

| Thread Size | 1/2″ – 24″ | 1/2″ – 24″ |

| Body Material | Cast Iron, Ductile Iron, Carbon Steel | Cast Iron, Ductile Iron, Carbon Steel |

| Safe for Use With | Water, Oil, Gas, Steam | Water, Oil, Gas, Steam |

| Handle Type | Handwheel, Gear Operated, Actuator | Handwheel, Gear Operated, Actuator |

| Handle Material | Cast Iron, Stainless Steel, Carbon Steel | Cast Iron, Stainless Steel, Carbon Steel |

| Maximum Working Pressure | Up to 600 psi (41.4 bar) | Up to 300 psi (20.7 bar) |

| Operating Pressure | Dependent on application | Dependent on application |

The Parameter of Gate Valve and Globe Valve

Type:

- Gate Valve: Rising Stem, OS & YGlobe Valve: Straight Pattern, Angle Pattern Ball Material:

- Gate Valve: Brass, Stainless Steel, Cast IronGlobe Valve: Brass, Stainless Steel, Cast Iron Attachment Type:

- Gate Valve: Flanged, Threaded, WeldedGlobe Valve: Flanged, Threaded, Welded Thread Standard:

- Gate Valve: ANSI, BS, DINGlobe Valve: ANSI, BS, DIN Thread Size:

- Gate Valve: 1/2″ – 24″Globe Valve: 1/2″ – 24″ Body Material:

- Gate Valve: Cast Iron, Ductile Iron, Carbon SteelGlobe Valve: Cast Iron, Ductile Iron, Carbon Steel Safe for Use With:

- Gate Valve: Water, Oil, Gas, SteamGlobe Valve: Water, Oil, Gas, Steam Handle Type:

- Gate Valve: Handwheel, Gear Operated, ActuatorGlobe Valve: Handwheel, Gear Operated, Actuator Handle Material:

- Gate Valve: Cast Iron, Stainless Steel, Carbon SteelGlobe Valve: Cast Iron, Stainless Steel, Carbon Steel Maximum Working Pressure:

- Gate Valve: Up to 600 psi (41.4 bar)Globe Valve: Up to 300 psi (20.7 bar) Operating Pressure:

- Gate Valve: Dependent on applicationGlobe Valve: Dependent on application

The Operation Theory of Gate Valve and Globe Valve

- Gate Valve: Operates by raising or lowering a gate (wedge) to control the flow of fluid. When the gate is lifted, it allows fluid to pass through the valve, and when it’s lowered, it obstructs the flow. Gate valves are typically used in applications where the flow needs to be completely shut off or fully open, such as in pipelines and large-scale industrial processes. They provide low resistance to fluid flow when fully open.

- Globe Valve: Functions by regulating flow with a movable plug or disc that closes against a stationary seat. The stem is typically perpendicular to the flow direction, allowing for precise control of flow rate. Globe valves are commonly used for throttling or regulating flow, as they offer fine control over the rate of fluid flow. They provide higher resistance to fluid flow compared to gate valves, making them suitable for applications requiring flow rate adjustment.

The Parameters Table of Gate Valve and Globe Valve

| Parameter | Gate Valve | Globe Valve |

|---|---|---|

| Type | Rising Stem, Non-Rising Stem | Angle, Y-pattern, Straight Pattern |

| Body Material | Cast Iron, Ductile Iron, Stainless Steel, Carbon Steel | Cast Iron, Ductile Iron, Stainless Steel, Bronze |

| Disc Material | Stainless Steel, Carbon Steel, Bronze | Stainless Steel, Carbon Steel, Bronze |

| Seat Material | Metal, EPDM, PTFE, NBR, Viton | Metal, EPDM, PTFE, NBR, Viton |

| Stem Material | Stainless Steel, Carbon Steel | Stainless Steel, Carbon Steel |

| Connection Type | Flanged, Threaded, Welded, Socket | Flanged, Threaded, Welded, Socket |

| Thread Standard | NPT, BSPT, BSPP | NPT, BSPT, BSPP |

| Thread Size | 1/2″ – 48″ | 1/2″ – 24″ |

| Maximum Working Pressure (psi) | Up to 5000 | Up to 2500 |

| Maximum Working Pressure (bar) | Up to 345 | Up to 172.5 |

| Operating Pressure | 0 to 3 bar | 0 to 3 bar |