Symbol Flow Control Valve

The Application of Flow Control Valve

Flow Control Valve, particularly valve flow control, plays a pivotal role in regulating fluid or gas flow rates in various systems. Air flow control valve is crucial in pneumatic applications, ensuring precise airflow management. In hydraulic systems, flow control valve hydraulic is instrumental in maintaining optimal fluid flow rates. Hyd flow control valve enhances efficiency in hydraulic circuits by controlling fluid volume. Cameron offers a comprehensive range of Flow Control Valves engineered to meet diverse industry needs. Whether it’s regulating air, fluid, or hydraulic flow, Cameron’s Flow Control Valves deliver reliable performance even in demanding environments. Ideal for applications requiring pressure regulation, these valves ensure smooth operation at 3 bar pressure.

What Is Flow Control Valve?

Flow Control Valve is a crucial component in fluid and gas systems, responsible for managing and regulating the rate of flow. It ensures precise control over the flow of liquids or gases within various applications, including hydraulic, pneumatic, and industrial systems. By adjusting the valve settings, users can efficiently manage the flow rate to meet specific requirements, improving system performance and overall efficiency.

How Does Flow Control Valve work?

- Adjustable Opening: Flow control valves feature an adjustable opening, which can be varied to control the flow of fluid or gas through the valve.

- Variable Restriction: By adjusting the opening size using the valve’s control mechanism, the amount of fluid passing through the valve can be increased or decreased.

- Control Mechanism: The control mechanism can vary depending on the type of flow control valve. It may involve a manual handle, an actuator, or an automated control system.

- Throttling or Regulating: Flow control valves can operate in either throttling or regulating mode. Throttling involves partially restricting the flow, while regulating involves maintaining a constant flow rate despite changes in pressure or demand.

- Feedback Control: Some flow control valves incorporate feedback mechanisms to monitor and adjust the flow rate automatically based on predefined parameters, ensuring precise control.

Features of Flow Control Valve

- Precise Flow Regulation: Flow control valves offer precise control over the flow rate of fluids or gases, allowing for accurate adjustment according to system requirements.

- Variety of Sizes and Configurations: Available in various sizes and configurations to accommodate different flow rates, pressures, and application needs.

- Durable Construction: Constructed from high-quality materials such as stainless steel, brass, or PVC, ensuring durability and longevity even in harsh operating conditions.

- Multiple Control Options: Can be operated manually, pneumatically, electrically, or through other automated systems, providing flexibility in control methods.

- Wide Range of Applications: Suitable for use in a wide range of industries and applications, including HVAC systems, water treatment plants, oil and gas refineries, and more.

- Leakage Prevention: Equipped with sealing mechanisms to minimize leakage and ensure efficient operation.

- Adaptable to System Changes: Designed to adapt to changes in system conditions, such as fluctuations in pressure or flow demand, to maintain optimal performance.

- Easy Installation and Maintenance: Designed for easy installation and maintenance, reducing downtime and operational costs over the valve’s lifespan.

Advantages of Flow Control Valve

Certainly, here are the advantages of flow control valves:

- Optimized Process Control: Flow control valves allow for precise regulation of fluid or gas flow, ensuring optimal process control and efficiency.

- Energy Savings: By maintaining consistent flow rates, flow control valves help minimize energy consumption, resulting in cost savings over time.

- Improved System Performance: These valves help maintain stable operating conditions within a system, leading to improved overall performance and reliability.

- Flexibility: Flow control valves offer flexibility in adjusting flow rates to match changing system requirements or operating conditions.

- Reduced Wear and Tear: By preventing sudden surges or fluctuations in flow, these valves help reduce wear and tear on downstream equipment, prolonging their lifespan.

- Enhanced Safety: Precise control over flow rates helps ensure safe operation of equipment and processes, minimizing the risk of accidents or damage.

- Customizable Solutions: Flow control valves come in various types and configurations, allowing for customized solutions tailored to specific application needs.

- Environmental Benefits: By optimizing flow rates and reducing energy consumption, flow control valves contribute to lower greenhouse gas emissions and environmental impact.

The Specifications of Flow Control Valve

| Specification | Details |

|---|---|

| Type | Flow Control Valve |

| Ball Material | Stainless Steel, Grade 316 |

| Attachment Type | Flanged |

| Thread Standard | N/A |

| Thread Size | N/A |

| Body Material | Cast Iron |

| Safe for Use With | Water, Oil, Gas |

| Handle Type | Handwheel |

| Handle Material | Steel |

| Maximum Working Pressure (psi) | 200 psi |

| Maximum Working Pressure (bar) | 13.8 bar |

| Operating Pressure | 0-150 psi (0-10.3 bar) |

The Parameter of Flow Control Valve

- Type: Flow Control Valve

- Ball Material: Stainless Steel, Grade 316

- Attachment Type: Flanged

- Thread Standard: N/A

- Thread Size: N/A

- Body Material: Cast Iron

- Safe for Use With: Water, Oil, Gas

- Handle Type: Handwheel

- Handle Material: Steel

- Maximum Working Pressure:

- psi: 200 psi

- bar: 13.8 bar

- Operating Pressure: 0-150 psi (0-10.3 bar)

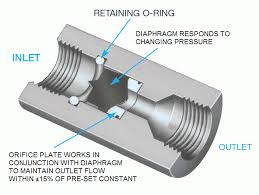

The Operation Theory of Flow Control Valve

- Pneumatic Flow Control Valve: In pneumatic systems, the valve adjusts the rate of airflow by modulating the size of the valve opening. This is typically achieved using a pneumatic actuator to position the valve stem or plug.

- Pressure Compensated Flow Control Valve: These valves maintain a constant flow rate despite changes in pressure. They achieve this by adjusting the size of the orifice in response to variations in pressure, ensuring a consistent flow.

- Excess Flow Control Valve: These valves are designed to restrict flow above a certain threshold to prevent overpressurization or excess flow in a system. They operate by automatically closing or throttling flow when the rate exceeds the preset limit.

The Parameters Table of Flow Control Valve

| Parameter | Specification |

|---|---|

| Type | Flow Control Valve |

| Ball Material | Stainless Steel, Brass, or Other Suitable Material |

| Attachment Type | Threaded, Flanged, Welded, or Compression Fitting |

| Thread Standard | ANSI, DIN, BSPT, NPT, JIS, or Other Standard |

| Thread Size | Various Sizes Available |

| Body Material | Stainless Steel, Brass, Aluminum, or Other Material |

| Safe for Use With | Various Fluids and Gases, Check Compatibility |

| Handle Type | Manual, Pneumatic, Electric, or Hydraulic Actuation |

| Handle Material | Stainless Steel, Plastic, or Other Material |

| Maximum Working Pressure | Dependent on Valve Size, Material, and Design |

| Maximum Working Pressure | Dependent on Valve Size, Material, and Design |

| Operating Pressure | Varies Depending on Application and System Requirements |