Vacuum Relief Valve

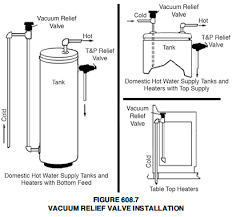

The Application of Vacuum Relief Valve

Introducing the Rotork Vacuum Relief Valve, an essential component in industrial systems for managing pressure differentials. Functioning akin to a 3/4 safety relief valve or a pressure relief valve for pressure washer, it ensures optimal performance by releasing excess pressure to maintain system integrity. Specifically designed for applications such as steam systems, the Rotork Vacuum Relief Valve effectively regulates pressure fluctuations, safeguarding equipment and personnel. With Rotork’s commitment to innovation and reliability, this valve stands as a trusted solution for diverse industrial needs. Trust Rotork to deliver high-quality Vacuum Relief Valves, ensuring safety and efficiency in your systems.

What Is Vacuum Relief Valve?

A Vacuum Relief Valve is a safety device used to prevent excessive vacuum buildup in a system by allowing air to enter when the pressure drops below a certain threshold.

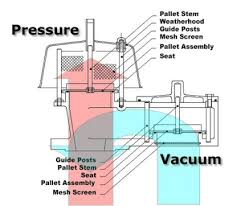

How Does Vacuum Relief Valve work?

The Vacuum Relief Valve works by opening to allow air into a system when the pressure drops below a set point, preventing excessive vacuum buildup and maintaining system integrity.

Features of Vacuum Relief Valve

- Pressure Regulation: Vacuum Relief Valves regulate pressure differentials within systems, preventing excessive vacuum buildup.

- Opening Mechanism: They employ a spring-loaded mechanism that opens the valve when the pressure drops below a predetermined level.

- Air Intake: These valves allow atmospheric air to enter the system, balancing the pressure and preventing damage.

- System Protection: Vacuum Relief Valves protect equipment and components from collapse or damage caused by excessive vacuum.

- Safety: They ensure the safety of personnel by maintaining safe pressure levels within the system.

- Versatility: These valves are versatile and suitable for various applications, including steam systems, storage tanks, and pipelines.

- Reliability: Vacuum Relief Valves offer reliable operation, ensuring consistent performance and system integrity.

- Easy Installation: They are easy to install and integrate into existing systems, requiring minimal maintenance.

- Material: Constructed from durable materials such as stainless steel, ensuring longevity and resilience in harsh environments.

Advantages of Vacuum Relief Valve

- Pressure Regulation: Vacuum Relief Valves effectively regulate pressure differentials within systems, preventing damage due to excessive vacuum.

- Equipment Protection: They safeguard equipment and components from collapse or damage caused by vacuum buildup.

- Safety: Vacuum Relief Valves ensure the safety of personnel by maintaining safe pressure levels within the system.

- Versatility: These valves are versatile and applicable in various industries and applications, including steam systems, storage tanks, and pipelines.

- Reliability: They offer reliable operation, ensuring consistent performance and system integrity.

- Cost-Effectiveness: Vacuum Relief Valves help minimize downtime and repair costs by preventing damage to equipment.

- Easy Installation: They are easy to install and integrate into existing systems, requiring minimal maintenance.

- Longevity: Constructed from durable materials, such as stainless steel, Vacuum Relief Valves exhibit longevity and resilience in harsh environments.

The Specifications of Vacuum Relief Valve

| Specification | Details |

|---|---|

| Type | Vacuum Relief Valve |

| Ball Material | N/A |

| Attachment Type | Threaded |

| Thread Standard | ANSI/ASME B1.20.1 |

| Thread Size | Various sizes available |

| Body Material | Stainless Steel |

| Safe for Use With | Various fluids and gases |

| Handle Type | Lever |

| Handle Material | Stainless Steel |

| Maximum Working Pressure | 150 psi |

| Maximum Working Pressure | 10.34 bar |

| Operating Pressure | Dependent on system settings |

The Parameter of Vacuum Relief Valve

- Type: Vacuum Relief Valve

- Ball Material: N/A

- Attachment Type: Threaded

- Thread Standard: ANSI/ASME B1.20.1

- Thread Size: Various sizes available

- Body Material: Stainless Steel

- Safe for Use With: Various fluids and gases

- Handle Type: Lever

- Handle Material: Stainless Steel

- Maximum Working Pressure: 150 psi (10.34 bar)

- Operating Pressure: Dependent on system settings

The Operation Theory of Vacuum Relief Valve

The operation theory of a Vacuum Relief Valve involves maintaining optimal pressure levels within a system. Similar to Conbraco safety relief valve, vacuum and pressure relief valve, and Farris safety relief valves, it opens when vacuum levels exceed the set threshold, allowing air to enter and preventing damage due to excessive vacuum. Conversely, it closes when pressure levels rise, preventing overpressure situations. This mechanism ensures system safety and integrity in various industrial applications.

The Parameters Table of Vacuum Relief Valve

| Parameter | Details |

|---|---|

| Type | Vacuum Relief Valve |

| Ball Material | N/A |

| Attachment Type | Threaded |

| Thread Standard | ANSI/ASME B1.20.1 |

| Thread Size | Various sizes available |

| Body Material | Stainless Steel |

| Seal Material | Rubber or Silicone |

| Spring Material | Stainless Steel |

| Safe for Use With | Various fluids and gases |

| Handle Type | Lever |