Linear Cage Control Valves

The Application of Linear Cage Control Valves

Introducing the Linear Cage Control Valve, a versatile solution offered by Cameron for precise fluid flow regulation. Combining the functionality of a Linear Control Valve with the stability of a Cage Control Valve, the Linear Cage Control Valve ensures accurate and reliable control across various industrial applications. With its innovative design, this valve optimizes flow rates while minimizing pressure fluctuations, enhancing operational efficiency and system performance. Trust Cameron for advanced solutions in fluid control.

What Are The Types Of Linear Cage Control Valves?

- Globe Valve: This type of valve features a linear motion stem and a spherical body, allowing for precise control of flow rates.

- Butterfly Valve: These valves use a circular disc as the closing mechanism, which rotates on a perpendicular axis to the flow direction to regulate fluid flow.

- Diaphragm Valve: Diaphragm valves use a flexible diaphragm to control the flow of fluids, making them suitable for handling corrosive or abrasive media.

- Needle Valve: Needle valves have a long, tapered needle-like stem that provides fine control over flow rates, making them ideal for applications requiring high precision.

- Ball Valve: Ball valves utilize a spherical closure unit to regulate flow. They offer quick operation and tight shut-off, making them suitable for a wide range of applications.

What Is Linear Cage Control Valves?

Linear Cage Control Valves are precision-engineered devices designed to regulate fluid flow by adjusting the position of a movable element within a cage structure. Combining the functionality of a linear control valve with the stability of a cage control valve, they offer precise flow control and stability across various industrial applications. These valves ensure accurate regulation of flow rates while minimizing pressure fluctuations, enhancing system efficiency and performance.

linear control valves

How to Select the Right Linear Cage Control Valves?

Selecting the right Linear Cage Control Valve involves considering factors such as flow requirements, pressure ratings, fluid characteristics, and environmental conditions. Begin by assessing the specific application requirements, including desired flow rates and pressure levels. Next, evaluate the compatibility of the valve materials with the fluid properties to ensure optimal performance and longevity. Consider environmental factors such as temperature and corrosion resistance. Lastly, consult with experts or manufacturers to determine the most suitable valve type and size for your application needs.

Features of Linear Cage Control Valves

- Precise Flow Control: Linear Cage Control Valves offer precise adjustment of flow rates, allowing for accurate regulation of fluid flow within a system.

- Stability: The cage structure provides stability to the valve, ensuring consistent performance even under varying pressure conditions.

- Reduced Noise: These valves are designed to minimize noise levels during operation, making them suitable for applications where noise reduction is critical.

- High Efficiency: With their ability to maintain stable flow rates, Linear Cage Control Valves contribute to the efficiency of industrial processes.

- Versatility: They are versatile and can be used in a wide range of industries and applications, including oil and gas, water treatment, and HVAC systems.

- Longevity: Constructed from durable materials, these valves offer long-lasting performance and require minimal maintenance, reducing downtime and operational costs.

Advantages and Disadvantages of Linear Cage Control Valves

Advantages:

- Precise Control: Linear Cage Control Valves offer precise regulation of flow rates, ensuring optimal system performance.

- Stability: The cage structure provides stability, reducing the likelihood of valve instability and improving reliability.

- Reduced Noise: These valves are designed to minimize noise levels during operation, creating a quieter working environment.

- High Efficiency: With their ability to maintain stable flow rates, Linear Cage Control Valves contribute to overall system efficiency.

- Versatility: They can be used across various industries and applications, providing flexibility in system design and operation.

Disadvantages:

- Complex Design: The cage structure and precision components can make Linear Cage Control Valves more complex to design and manufacture.

- Higher Cost: The precision engineering and materials required for these valves may result in higher initial costs compared to simpler valve designs.

- Maintenance: While they generally require minimal maintenance, the complexity of Linear Cage Control Valves can make repairs and servicing more challenging.

- Pressure Drop: In some applications, the cage structure may contribute to a higher pressure drop across the valve, impacting system efficiency.

- Limited Flow Capacity: Linear Cage Control Valves may have limited flow capacities compared to other valve types, restricting their use in high-flow applications.

The Specifications of Linear Cage Control Valves

| Specification | Details |

|---|---|

| Type | Linear Cage Control Valve |

| Ball Material | Stainless Steel, Brass, or other alloys |

| Attachment Type | Flanged, Threaded, Welded, or Socket Weld |

| Thread Standard | ANSI, DIN, JIS, BS, or custom |

| Thread Size | Typically ranging from 1/4″ to 4″ |

| Body Material | Stainless Steel, Cast Iron, Carbon Steel, etc. |

| Safe for Use With | Water, Oil, Gas, Steam, Various Chemicals, etc. |

| Handle Type | Lever, Handwheel, Pneumatic Actuator, Electric Actuator, etc. |

| Handle Material | Aluminum, Stainless Steel, Plastic, etc. |

| Maximum Working Pressure (psi) | Specific to model and size |

| Maximum Working Pressure (bar) | Specific to model and size |

| Operating Pressure | Depends on application and operating conditions |

The Installation Steps for Linear Cage Control Valves

- Preparation:

- Ensure the work area is clean and free from debris.

- Gather all necessary tools and equipment, including wrenches, gaskets, and sealing compounds.

- Valve Inspection:

- Check the valve body and components for any damage or defects.

- Verify that the valve size and specifications match the installation requirements.

- Positioning:

- Determine the correct orientation of the valve based on the flow direction and system layout.

- Align the valve with the pipeline, ensuring proper positioning for optimal performance.

- Mounting:

- Securely fasten the valve to the pipeline using appropriate mounting hardware.

- Ensure that the valve is tightly sealed and properly aligned to prevent leaks.

- Connection:

- Connect the valve to the upstream and downstream piping using compatible fittings.

- Tighten all connections according to manufacturer specifications to prevent leaks.

- Testing:

- Conduct a pressure test to check for any leaks or defects in the installation.

- Verify that the valve operates smoothly and effectively controls the flow as intended.

- Adjustment:

- Make any necessary adjustments to the valve settings or position to achieve the desired flow control.

- Final Inspection:

- Perform a final inspection of the installation to ensure all components are secure and properly aligned.

- Confirm that the valve operates correctly under normal operating conditions.

- Documentation:

- Record all relevant installation details, including valve specifications, test results, and any adjustments made.

The Operation Theory of Linear Cage Control Valves

- Linear Motion Mechanism:

- Linear Cage Control Valves operate on the principle of linear motion, where the valve stem moves in a straight line to control the flow of fluid through the valve.

- The linear movement of the valve stem is translated into a corresponding change in the position of the valve plug or disc, regulating the flow area and thus controlling the fluid flow rate.

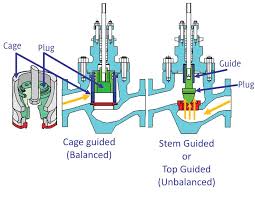

- Cage Design:

- The cage design in Linear Cage Control Valves plays a crucial role in enhancing control accuracy and reducing noise and vibration.

- The cage surrounds the valve plug or disc, providing stability and guiding its linear motion within the valve body.

- Flow Regulation:

- By adjusting the position of the valve plug or disc along its linear path, Linear Cage Control Valves can precisely regulate the flow of fluid through the valve.

- Changes in stem position result in proportional adjustments to the flow area, allowing for fine-tuning of flow rates to meet process requirements.

- Linear Valve Applications:

- Linear Cage Control Valves are commonly used in applications requiring precise flow control, such as process industries, water treatment plants, and HVAC systems.

- They excel in applications where linear control is essential for maintaining desired process parameters, such as pressure, temperature, or fluid level.

- Linear Regulating Valve Functionality:

- Linear Regulating Valves are a specific type of Linear Cage Control Valve designed for accurate regulation of fluid flow in industrial processes.

- They offer linear control characteristics, allowing for precise adjustment of flow rates to achieve desired process conditions.