Bellows Valve

The Application of Bellows Valve

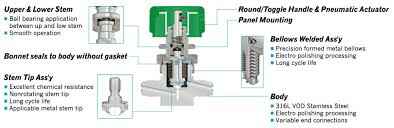

Introducing the Bellows Valve from Cameron: This valve, also known as a bellow seal globe valve or bellow seal valve, is engineered with precision to ensure optimal performance in various applications, including those with pressure requirements of up to 3 bars. With its unique design featuring a bellows seal, this valve offers enhanced reliability and leak-proof operation, making it ideal for critical applications where tight shut-off is essential. The bellow globe valve design provides excellent throttling control and is often preferred for its ability to handle high-pressure and high-temperature conditions with minimal maintenance. Cameron’s Bellows Valve is trusted for its durability, longevity, and superior sealing capabilities, making it a top choice for industries requiring precision flow control and safety assurance.

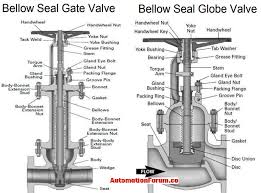

What Is Bellows Valve?

A Bellows Valve is a type of valve equipped with a bellows seal, designed to provide reliable sealing in various industrial applications. The bellows seal, typically made of metal, creates a flexible barrier that prevents leaks and ensures tight shut-off, even in high-pressure and high-temperature environments. This valve design offers superior performance and durability, making it suitable for critical applications where precision flow control and leak prevention are paramount. Bellows valves are commonly used in industries such as petrochemical, pharmaceutical, and power generation, where safety and efficiency are essential considerations.

How Does Bellows Valve work?

The Bellows Valve operates by utilizing a flexible bellows seal to ensure tight shut-off and prevent leaks. When the valve is closed, the bellows compresses to seal the flow path completely, preventing fluid from escaping. When the valve is opened, the bellows expands, allowing fluid to flow through the valve. This design provides excellent sealing performance, even in high-pressure and high-temperature conditions, making it suitable for demanding industrial applications. Additionally, the bellows seal eliminates the need for external packing, reducing maintenance requirements and minimizing the risk of fugitive emissions.

Features of Bellows Valve

- Bellows Seal: Utilizes a flexible bellows seal to ensure tight shut-off and prevent leaks, even in high-pressure and high-temperature conditions.

- Compact Design: Features a compact and space-saving design, making it suitable for installations with limited space.

- Corrosion Resistance: Constructed from corrosion-resistant materials such as stainless steel or alloy, ensuring durability and longevity in harsh environments.

- Zero Leakage: Offers zero leakage performance, thanks to the bellows seal design, providing reliable operation and minimizing the risk of fluid loss.

- Maintenance-Free: Requires minimal maintenance due to the absence of external packing, reducing downtime and maintenance costs.

- Versatile Application: Suitable for a wide range of applications, including chemical processing, petrochemical, oil and gas, and pharmaceutical industries, where tight shut-off and leak-free operation are critical.

Advantages of Bellows Valve

- Leak-Free Operation: The bellows seal design ensures zero leakage, even in high-pressure and high-temperature environments, providing reliable performance and preventing fluid loss.

- Longevity: Constructed from durable materials such as stainless steel or alloy, bellows valves offer long service life and resistance to corrosion, extending the lifespan of the valve and reducing the need for frequent replacements.

- Safety: With their tight shut-off capability, bellows valves enhance safety by preventing hazardous leaks and minimizing the risk of accidents or environmental damage.

- Maintenance Reduction: Bellows valves require minimal maintenance due to their robust design and the absence of external packing, reducing downtime and maintenance costs over time.

- Versatility: Suitable for a wide range of applications across various industries, bellows valves offer versatility in fluid control and are compatible with different types of media, including corrosive and abrasive fluids.

The Specifications of Bellows Valve

| Specification | Details |

|---|---|

| Type | Bellows Seal Globe Valve |

| Ball Material | Stainless Steel |

| Attachment Type | Flanged |

| Thread Standard | N/A |

| Thread Size | N/A |

| Body Material | Carbon Steel, Stainless Steel, Alloy |

| Safe for Use With | Various fluids including corrosive and abrasive |

| Handle Type | Handwheel, Gear Operated, Pneumatic Actuator |

| Handle Material | Carbon Steel, Stainless Steel |

| Maximum Working Pressure psi | Up to 3000 psi |

| Maximum Working Pressure bar | Up to 207 bar |

| Operating Pressure | Depends on specific model and application |

The Parameter of Bellows Valve

- Type: Bellows Seal Globe Valve

- Ball Material: Stainless Steel

- Attachment Type: Flanged

- Thread Standard: N/A

- Thread Size: N/A

- Body Material: Carbon Steel, Stainless Steel, Alloy

- Safe for Use With: Various fluids including corrosive and abrasive

- Handle Type: Handwheel, Gear Operated, Pneumatic Actuator

- Handle Material: Carbon Steel, Stainless Steel

- Maximum Working Pressure psi: Up to 3000 psi

- Maximum Working Pressure bar: Up to 207 bar

- Operating Pressure: Depends on specific model and application

The Operation Theory of Bellows Valve

- Bellows Seal Valve Applications: Bellows valves are commonly used in applications requiring zero leakage, such as high-purity fluid systems, corrosive environments, and cryogenic systems.

- Schrader Bellows Flow Control Valve: Schrader bellows flow control valves regulate the flow of fluids or gases in a system. They operate by adjusting the position of the bellows, which in turn alters the flow rate through the valve.

The Parameters Table of Bellows Valve

| Parameter | Specification |

|---|---|

| Type | Bellows Valve |

| Body Material | Stainless Steel, Carbon Steel, Brass, etc. |

| Bellows Material | Stainless Steel, Inconel, Hastelloy, etc. |

| Seat Material | PTFE, Graphite, Metal, etc. |

| Stem Material | Stainless Steel, Alloy Steel, etc. |

| Connection Type | Flanged, Threaded, Welded, etc. |

| Thread Standard | ANSI, DIN, BS, JIS, etc. |

| Thread Size | Various (Specify Size) |

| Safe for Use With | Liquids, Gases, Steam, etc. |

| Maximum Working Pressure | Specified by Manufacturer (e.g., 300 psi) |

| Maximum Working Pressure | Specified by Manufacturer (e.g., 20 bar) |

| Operating Pressure | Specified by Manufacturer (e.g., 3 bar) |