Fisher Control Valves

The Application of Fisher Control Valves

Fisher Control Valves, a renowned product line under Cameron, offer precision engineering for various industrial applications. These valves, known for their reliability and performance, are widely used in diverse sectors worldwide. The Fisher Control Valve Repair services ensure longevity and efficiency, backed by comprehensive maintenance support. The Fisher Control Valve Handbook serves as a comprehensive guide, aiding users in installation, operation, and troubleshooting. With cutting-edge technology and decades of expertise, Fisher Controls Valves deliver unparalleled control over flow, pressure, and temperature, making them the preferred choice for critical processes. At 3 bar, Fisher Control Valves exhibit optimal performance, maintaining precise control even under challenging conditions.

gear operated butterfly valve

butterfly valves vs ball valves

innovations intec ball valves

What Is Fisher Control Valves?

Fisher Control Valves are a flagship product line offered by Cameron, renowned for their precision engineering and reliability. These valves provide precise control over flow, pressure, and temperature in various industrial applications, ensuring optimal performance and efficiency.

How Does Fisher Control Valves work?

Fisher Control Valves operate by modulating the flow of fluid or gas through a piping system to maintain desired process conditions. They utilize a combination of mechanical components and advanced control algorithms to adjust the valve position in response to changes in pressure, temperature, or flow rate, ensuring precise regulation and optimal performance.

Features of Fisher Control Valves

- Precision Control: Fisher Control Valves offer exceptional accuracy in regulating flow rates, ensuring precise control over process variables.

- Reliability: Engineered with high-quality materials and robust construction, Fisher valves are known for their durability and long service life.

- Versatility: Designed to handle a wide range of fluids and gases, Fisher valves are suitable for various industrial applications.

- Ease of Maintenance: With user-friendly designs and accessible components, Fisher valves are easy to install, operate, and maintain.

- Adaptability: Fisher valves can be customized with different trim options, accessories, and actuation methods to meet specific process requirements.

- Advanced Technology: Incorporating state-of-the-art control algorithms and digital communication capabilities, Fisher valves offer advanced functionality and integration with modern control systems.

Advantages of Fisher Control Valves

- High Performance: Fisher Control Valves deliver exceptional performance in terms of accuracy, repeatability, and response time, ensuring precise control over process variables.

- Reliability: Known for their robust construction and reliable operation, Fisher valves offer uninterrupted performance even in demanding industrial environments.

- Versatility: With a wide range of sizes, materials, and configurations available, Fisher valves are suitable for diverse applications across various industries.

- Cost-Effectiveness: Fisher valves are designed for efficiency, helping to optimize processes and reduce operational costs over the long term.

- Global Support: Fisher valves are backed by a global network of service centers and technical experts, providing reliable support and assistance whenever needed.

- Innovation: Fisher continuously invests in research and development, introducing new technologies and features to enhance valve performance and reliability.

The Specifications of Fisher Control Valves

| Specification | Details |

|---|---|

| Type | Control Valve |

| Ball Material | Varies depending on application |

| Attachment Type | Flanged, Threaded, Welded, etc. |

| Thread Standard | ANSI, API, DIN, BS, etc. |

| Thread Size | Varies depending on valve size |

| Body Material | Carbon Steel, Stainless Steel, etc. |

| Safe for Use With | Various fluids, gases, and steam |

| Handle Type | Handwheel, Lever, Actuator, etc. |

| Handle Material | Stainless Steel, Carbon Steel, etc. |

| Maximum Working Pressure (psi) | Varies depending on valve model |

| Maximum Working Pressure (bar) | Varies depending on valve model |

| Operating Pressure | Varies depending on valve model |

The Parameter of Fisher Control Valves

- Type: Fisher Control Valves are specialized valves designed for precise control of flow rates in various industrial processes.

- Body Material: They are available in a range of materials including carbon steel, stainless steel, and others, chosen based on the specific application requirements.

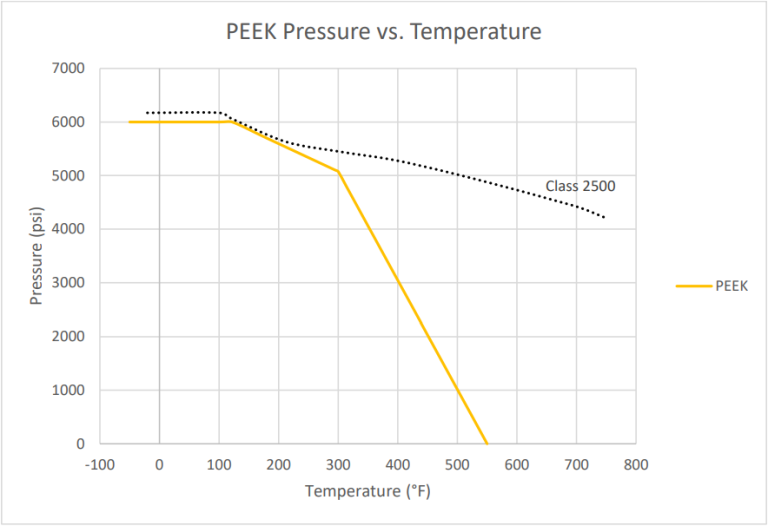

- Maximum Working Pressure: Depending on the model, Fisher Control Valves can handle pressures ranging from a few psi to several thousand psi, ensuring compatibility with a wide range of systems.

- Maximum Working Temperature: These valves can operate effectively within a broad temperature range, from sub-zero temperatures to high-temperature industrial environments.

- Control Mechanism: Fisher Control Valves utilize sophisticated control mechanisms such as pneumatic actuators, electric actuators, or hydraulic actuators for precise flow control.

- Valve Size: Available in various sizes ranging from small-diameter valves suitable for laboratory applications to large-diameter valves for industrial processes.

- Flow Characteristics: They offer different flow characteristics such as linear, equal percentage, or quick opening, allowing for tailored control based on process requirements.

- Sealing Mechanism: Fisher Control Valves employ reliable sealing mechanisms such as globe valve, butterfly valve, or ball valve configurations to ensure tight shut-off and prevent leakage.

- Actuation Options: These valves can be manually operated or equipped with automatic actuators for remote operation and integration into control systems.

- Certifications: Fisher Control Valves may come with certifications such as API, ANSI, ISO, and others, ensuring compliance with industry standards and regulations.

The Operation Theory of Fisher Control Valves

- Control Mechanism: Fisher Control Valves utilize a sophisticated control mechanism to regulate the flow of fluids or gases through the valve. This mechanism can vary depending on the specific type of Fisher Control Valve being used, such as globe control valve, butterfly valve, or ball valve.

- Actuation: Fisher Control Valves can be actuated manually or automatically using pneumatic, electric, or hydraulic actuators. These actuators translate control signals from a control system or operator into valve position changes, allowing for precise control over the flow rate.

- Flow Characteristics: Fisher Control Valves are designed to provide different flow characteristics, such as linear, equal percentage, or quick opening. This allows for tailored control of the flow rate to meet the specific requirements of the process being controlled.

- Positioner: Many Fisher Control Valves are equipped with positioners that ensure accurate valve positioning based on input signals from the control system. This helps maintain the desired flow rate even in the presence of fluctuations in system pressure or other variables.

- Catalogue: Fisher Control Valves are often available with detailed catalogues that provide comprehensive information about the valve’s specifications, performance characteristics, installation guidelines, maintenance requirements, and more. These catalogues serve as valuable resources for engineers, operators, and maintenance personnel involved in the selection, installation, and operation of Fisher Control Valves.

The Parameters Table of Fisher Control Valves

| Parameter | Details |

|---|---|

| Valve Type | Control Valve |

| Body Material | Stainless Steel |

| Trim Material | Stainless Steel |

| Seat Material | Metal or Soft Seated |

| Bonnet Material | Carbon Steel |

| Actuator Type | Pneumatic or Electric |

| Connection Type | Flanged or Threaded |

| Maximum Pressure Rating (psi) | Up to 6000 |

| Maximum Temperature Rating (°F) | Up to 1000 |

| Flow Characteristic | Equal Percentage or Linear |

| Leakage Class | ANSI Class IV to VI |