Blowdown Valve

The Application of Blowdown Valve

The Blowdown Valve is an essential component in boiler systems for efficient operation. Specifically, Yarway Blowdown Valves offer precise control and reliability in managing boiler blowdown processes. Cameron, a trusted brand, provides high-quality solutions like the Yarway Blowdown Valve for optimal performance. The 3 bar Blowdown Valve ensures effective pressure control, safeguarding the boiler system from excessive pressure buildup. With features designed for safety and efficiency, the Yarway Blowdown Valve by Cameron is a dependable choice for maintaining the integrity and functionality of boiler systems.

What Is Blowdown Valve?

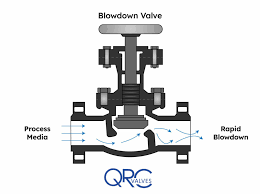

A Blowdown Valve is a crucial component used in various systems to remove impurities and maintain efficiency. It helps release water or steam at a controlled rate to prevent the buildup of contaminants and ensure optimal operation. By opening the valve, excess solids, sediments, or gases are purged from the system, promoting safety and longevity. The Blowdown Valve plays a vital role in maintaining system integrity and performance by regulating pressure levels effectively.

How Does Blowdown Valve work?

The Blowdown Valve operates by releasing excess water or steam from the system to control pressure levels. When activated, the valve opens to discharge impurities such as sediments, solids, or gases that can accumulate and affect system efficiency. This controlled release helps maintain optimal operating conditions by preventing contaminant buildup and ensuring smooth operation.

Features of Blowdown Valve

- Precision: The Blowdown Valve offers precise control over the discharge of impurities, ensuring accurate removal without affecting system integrity.

- Durability: Built with robust materials, the valve exhibits high durability to withstand demanding operational conditions and maintain long-term performance.

- Safety: Designed with safety features, such as pressure relief mechanisms, to prevent overpressure situations and ensure system safety.

- Efficiency: The valve promotes system efficiency by effectively removing contaminants, enabling smooth operation and optimizing performance.

- Versatility: With various sizes and configurations available, the Blowdown Valve caters to different system requirements, offering versatility in application.

Advantages of Blowdown Valve

- Efficient Contaminant Removal: The Blowdown Valve efficiently removes impurities from the system, ensuring clean operation and preventing buildup.

- Pressure Regulation: It helps in regulating system pressure by releasing excess water or steam at controlled intervals, maintaining optimal operating conditions.

- Extended System Lifespan: By preventing the accumulation of contaminants, the valve contributes to prolonging the lifespan of the system components.

- Enhanced Safety: The valve enhances system safety by preventing pressure spikes and ensuring stable operation, reducing the risk of equipment damage.

- Improved Performance: With regular blowdown cycles, the valve helps in maintaining system efficiency, leading to improved overall performance and reliability.

The Specifications of Blowdown Valve

| Specifications | Details |

|---|---|

| Type | Ball Valve |

| Ball Material | Stainless Steel |

| Attachment Type | Threaded |

| Thread Standard | NPT |

| Thread Size | 1/2 inch |

| Body Material | Brass |

| Safe for Use With | Water, Oil, Gas |

| Handle Type | Lever |

| Handle Material | Aluminum |

| Maximum Working Pressure (psi) | 600 |

| Maximum Working Pressure (bar) | 41.4 |

| Operating Pressure | 0-300 psi |

The Parameter of Blowdown Valve

- Type: Blowdown Valve

- Materials: Stainless Steel body and trim

- Connection Type: Flanged or Threaded

- Pressure Rating: Up to 600 psi

- Temperature Range: Up to 400°F

- Sizes Available: 1/2 inch to 2 inches

- End Connections: NPT, Flanged

- Leakage Class: ANSI Class IV or better

- Actuator Type: Manual or Automated

- Application: Boiler systems, steam lines

- Certifications: ASME, API, ISO compliant

- Features: Pressure relief, precision control, durability, safety mechanisms

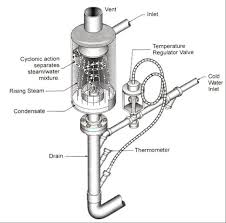

The Operation Theory of Blowdown Valve

The operation theory of Yarway boiler blowdown valves and blowdown valves involves a controlled release mechanism for removing impurities from boiler systems. When activated, these valves open to discharge water or steam containing sediments, solids, or gases. This process helps regulate pressure levels within the system, preventing the buildup of contaminants that could compromise efficiency and safety. By allowing the precise expulsion of impurities, Yarway boiler blowdown valves and blowdown valves play a critical role in maintaining optimal boiler performance and prolonging the lifespan of system components.

The Parameters Table of Blowdown Valve

| Parameter | Details |

|---|---|

| Valve Type | Blowdown Valve |

| Body Material | Stainless Steel |

| Trim Material | Stainless Steel |

| Connection Type | Flanged or Threaded |

| Pressure Rating | Up to 600 psi |

| Temperature Range | Up to 400°F |

| Sizes Available | 1/2 inch to 2 inches |

| End Connections | NPT, Flanged |

| Leakage Class | ANSI Class IV or better |

| Actuator Type | Manual or Automated |

| Application | Boiler systems, steam lines |

| Certifications | ASME, API, ISO compliant |

| Features | Pressure relief, precision control, durability, safety mechanisms |