Globe Valve Vs Ball Valve

The Application of Globe Valve Vs Ball Valve

Globe Valve:

- Ideal for precise flow regulation in various industries, including pool systems.

- Prevents leaks, even at the handle, ensuring system integrity and safety.

- Offers reliable performance, especially in situations requiring throttling.

Ball Valve:

- Commonly used in applications like pool systems, featuring options like 2 piece ball valve.

- May experience leakage at the handle if not properly maintained or due to wear and tear.

- Provides quick and easy on/off control with minimal pressure drop.

Comparison:

- Globe valves excel in precise flow control and are suitable for throttling applications.

- Ball valves are versatile, offering quick on/off control, but may require regular maintenance to prevent leaks.

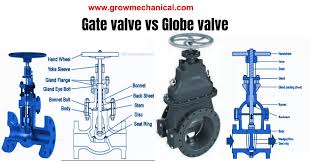

What Is Globe Valve Vs Ball Valve?

Globe Valve Vs Ball Valve refers to two distinct types of valves used in fluid control systems.

A globe valve regulates flow through a system with a plug (often referred to as a disc or a ball) that moves perpendicular to the flow path. In contrast, a ball valve controls flow with a spherical disc (the ball) that pivots perpendicular to the direction of flow.

While both valves serve similar functions, their designs and mechanisms differ, leading to variations in their applications and performance characteristics.

How Does Globe Valve Vs Ball Valve work?

Globe Valve operates by using a plug (disc) that moves perpendicular to the flow path, regulating flow rates. Ball Valve utilizes a spherical disc (the ball) that rotates perpendicular to the flow direction, controlling fluid flow by opening or closing the passage. Both valves offer efficient flow control, but their mechanisms differ, leading to variations in performance and applications.

Features of Globe Valve Vs Ball Valve

- Globe Valve:

- Precise Control: Offers precise regulation of flow rates and pressure due to its design, making it suitable for throttling applications.

- Robust Construction: Constructed with a sturdy body and internal components, ensuring durability and longevity.

- Reliable Sealing: Provides tight shut-off to prevent leakage, enhancing system integrity and safety.

- Versatility: Suitable for a wide range of fluid types and operating conditions, offering flexibility in applications.

- Throttling Capability: Well-suited for applications requiring smooth and gradual adjustments to flow rates.

- Ball Valve:

- Quick On/Off Control: Provides fast and easy on/off control, making it ideal for applications requiring rapid flow adjustment.

- Minimal Pressure Drop: Offers minimal resistance to flow when fully open, reducing energy consumption and maximizing efficiency.

- Simple Design: Features a straightforward design with few moving parts, resulting in easy maintenance and reduced downtime.

- Wide Range of Sizes: Available in various sizes, from small 2-piece ball valves to larger industrial models, accommodating different flow rates and system requirements.

- Versatility: Suitable for a wide range of applications, including ball valve pool systems, water distribution, and industrial processes.

Advantages of Globe Valve Vs Ball Valve

- Advantages of Globe Valve:

- Precise Flow Regulation: Globe valves offer precise control over flow rates and pressure, making them ideal for applications requiring accurate adjustments.

- Reliable Sealing: Globe valves provide tight shut-off to prevent leakage, ensuring system integrity and safety.

- Versatility: Suitable for a wide range of fluid types and operating conditions, offering flexibility in applications.

- Throttling Capability: Well-suited for throttling applications, allowing for smooth and gradual adjustments to flow rates.

- Robust Construction: Constructed with durable materials, globe valves offer longevity and reliability, even in harsh environments.

- Advantages of Ball Valve:

- Quick On/Off Control: Ball valves provide fast and easy on/off control, making them ideal for applications requiring rapid flow adjustment.

- Minimal Pressure Drop: Offer minimal resistance to flow when fully open, maximizing efficiency and reducing energy consumption.

- Simple Maintenance: Features a straightforward design with few moving parts, resulting in easy maintenance and reduced downtime.

- Wide Range of Sizes: Available in various sizes to accommodate different flow rates and system requirements.

- Versatility: Suitable for a wide range of applications, including ball valve pool systems, water distribution, and industrial processes.

The Specifications of Globe Valve Vs Ball Valve

| Specification | Globe Valve | Ball Valve |

|---|---|---|

| Type | Globe Valve | Ball Valve |

| Ball Material | Stainless steel, brass, or other corrosion-resistant material | Stainless steel, brass, or other corrosion-resistant material |

| Attachment Type | Flanged, threaded, or welded connections | Flanged, threaded, or welded connections |

| Thread Standard | ANSI, BSPP, NPT, or DIN standards | ANSI, BSPP, NPT, or DIN standards |

| Thread Size | Varies depending on valve size and type | Varies depending on valve size and type |

| Body Material | Stainless steel, cast iron, or bronze | Stainless steel, cast iron, or bronze |

| Safe for Use With | Water, air, oil, gas, or other compatible fluids | Water, air, oil, gas, or other compatible fluids |

| Handle Type | Handwheel, lever, or actuator | Lever, handwheel, or actuator |

| Handle Material | Steel, aluminum, or other durable material | Steel, aluminum, or other durable material |

| Maximum Working Pressure (psi) | Varies depending on valve size, type, and material | Varies depending on valve size, type, and material |

| Maximum Working Pressure (bar) | Varies depending on valve size, type, and material | Varies depending on valve size, type, and material |

| Operating Pressure | Varies based on system requirements and valve specifications | Varies based on system requirements and valve specifications |

The Parameter of Globe Valve Vs Ball Valve

- Type:

- Globe Valve: Typically used for throttling applications, allowing precise regulation of flow rates.

- Ball Valve: Ideal for on/off applications, offering quick and easy control over fluid flow.

- Ball Material:

- Globe Valve: Utilizes materials such as stainless steel, brass, or other corrosion-resistant materials for the ball.

- Ball Valve: Also employs materials like stainless steel, brass, or other corrosion-resistant materials for the ball.

- Attachment Type:

- Globe Valve: Offers attachment options like flanged, threaded, or welded connections.

- Ball Valve: Provides similar attachment options including flanged, threaded, or welded connections.

- Thread Standard:

- Globe Valve: Conforms to industry standards such as ANSI, BSPP, NPT, or DIN.

- Ball Valve: Also adheres to industry standards such as ANSI, BSPP, NPT, or DIN.

- Thread Size:

- Globe Valve: Varies depending on the valve size and type, accommodating different system requirements.

- Ball Valve: Similar to Globe Valve, thread size varies depending on the valve size and type.

- Body Material:

- Globe Valve: Constructed from materials like stainless steel, cast iron, or bronze, ensuring durability.

- Ball Valve: Also constructed from materials like stainless steel, cast iron, or bronze for robustness.

- Safe for Use With:

- Globe Valve: Suitable for use with water, air, oil, gas, or other compatible fluids commonly used in industrial processes.

- Ball Valve: Similarly suitable for use with water, air, oil, gas, or other compatible fluids.

- Handle Type:

- Globe Valve: Equipped with handwheel, lever, or actuator for manual or automated operation.

- Ball Valve: Similarly equipped with lever, handwheel, or actuator for manual or automated operation.

- Handle Material:

- Globe Valve: Handles are typically made of steel, aluminum, or other durable materials for reliable operation.

- Ball Valve: Handles are also made of steel, aluminum, or other durable materials for consistent performance.

- Maximum Working Pressure (psi/bar):

- Globe Valve: Maximum working pressure varies depending on valve size, type, and material.

- Ball Valve: Similar to Globe Valve, maximum working pressure varies depending on valve size, type, and material.

- Operating Pressure:

- Globe Valve: Operating pressure varies based on system requirements and valve specifications.

- Ball Valve: Operating pressure also varies based on system requirements and valve specifications

The Operation Theory of Globe Valve Vs Ball Valve

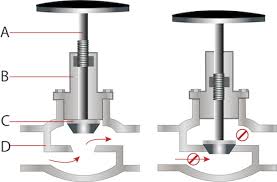

- Globe Valve Operation:

- Globe Valve Valves: The flow of fluid is regulated by a plug or disc that moves perpendicular to the flow path, controlling the flow rates. When the valve is closed, the plug tightly seals against the valve seat, preventing fluid from passing through. When opened, the plug moves away from the seat, allowing fluid to flow through the valve.

- Ball Valve Operation:

- Ball Valve Open or Closed: Ball valves operate by using a spherical disc (the ball) that rotates perpendicular to the flow direction. When the valve is closed, the ball is positioned perpendicular to the flow path, blocking fluid flow. Conversely, when the valve is open, the ball rotates 90 degrees, aligning with the flow path and allowing fluid to pass through the valve.

The Parameters Table of Globe Valve Vs Ball Valve

| Parameter | Globe Valve | Ball Valve |

|---|---|---|

| Type | Globe Valve | Ball Valve |

| Material | Stainless steel, brass, or other corrosion-resistant material | Stainless steel, brass, or other corrosion-resistant material |

| Attachment Type | Flanged, threaded, or welded connections | Flanged, threaded, or welded connections |

| Thread Standard | ANSI, BSPP, NPT, or DIN standards | ANSI, BSPP, NPT, or DIN standards |

| Thread Size | Varies depending on valve size and type | Varies depending on valve size and type |

| Body Material | Stainless steel, cast iron, or bronze | Stainless steel, cast iron, or bronze |

| Safe for Use With | Water, air, oil, gas, or other compatible fluids | Water, air, oil, gas, or other compatible fluids |

| Handle Type | Handwheel, lever, or actuator | Lever, handwheel, or actuator |

| Handle Material | Steel, aluminum, or other durable material | Steel, aluminum, or other durable material |

| Maximum Working Pressure | Varies depending on valve size, type, and material | Varies depending on valve size, type, and material |

| Operating Pressure | Varies based on system requirements and valve specifications | Varies based on system requirements and valve specifications |