Fcv Valve

The Application of Fcv Valve

FCV Valve is a critical component in fluid control systems, known for its precision and reliability. As a FCV control valve or FCV flow control valve, it regulates the flow rate of fluids in pipelines, ensuring optimal performance and efficiency. The valve’s operation is often represented by the FCV valve symbol in engineering diagrams, highlighting its significance in fluid dynamics. Engineered to withstand pressures of up to 3 bars, FCV valves find wide application across industries, including oil and gas, chemical processing, water treatment, and more. With their robust construction and precise flow control capabilities, FCV valves play a vital role in maintaining system integrity and maximizing operational productivity.

What Is Fcv Valve?

FCV Valve, short for Flow Control Valve, is a pivotal component in fluid management systems. It regulates the flow of fluids within pipelines, ensuring precise control and optimal performance. FCV Valves are engineered with precision to maintain desired flow rates, enhancing efficiency and system reliability. These valves find extensive application across various industries, including oil and gas, chemical processing, and water treatment, where precise fluid control is paramount. With their ability to handle pressures of up to 3 bars, FCV Valves play a crucial role in maintaining system integrity and maximizing operational efficiency.

How Does Fcv Valve work?

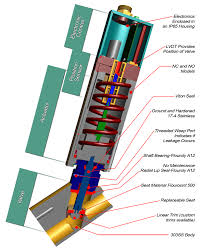

FCV Valve operates by controlling the flow of fluids within pipelines. When fluid enters the valve, it encounters a mechanism that adjusts the valve opening based on preset parameters. This mechanism, often comprising a flow control element such as a plug or a ball, regulates the flow rate by either restricting or allowing more fluid to pass through. By adjusting the position of this element, the FCV Valve can maintain the desired flow rate, ensuring optimal performance and efficiency in fluid systems.

Features of Fcv Valve

- Precision Control: FCV Valves offer precise control over fluid flow rates, ensuring accurate adjustment according to system requirements.

- Durable Construction: Built with robust materials such as stainless steel or brass, FCV Valves are designed to withstand harsh operating conditions and resist corrosion.

- Versatile Applications: Suitable for a wide range of industries and fluid types, including water, oil, gas, and chemicals, FCV Valves demonstrate versatility in application.

- Modular Design: Featuring a modular design, FCV Valves allow for easy maintenance and repair, minimizing downtime and ensuring continuous operation.

- Reliable Performance: Engineered with high-quality components and precision machining, FCV Valves deliver reliable performance over extended periods, reducing the risk of system failures.

Advantages of Fcv Valve

- Precise Flow Control: FCV Valves offer precise regulation of fluid flow rates, allowing for accurate adjustment to meet specific system requirements.

- Efficient Operation: By maintaining optimal flow rates, FCV Valves ensure efficient operation of fluid systems, minimizing energy consumption and operational costs.

- Versatility: With their ability to handle various fluid types and operating conditions, FCV Valves offer versatility in application across different industries and environments.

- Improved System Performance: The precise control provided by FCV Valves enhances overall system performance, resulting in smoother operation and reduced downtime.

- Cost-Effectiveness: By optimizing fluid flow and minimizing wastage, FCV Valves contribute to cost savings over the long term, making them a cost-effective solution for fluid control needs.

The Specifications of Fcv Valve

| Specification | Details |

|---|---|

| Type | Flow Control Valve |

| Ball Material | Stainless Steel |

| Attachment Type | Flanged, Threaded |

| Thread Standard | ANSI, DIN, JIS |

| Thread Size | 1/2 inch to 4 inches |

| Body Material | Cast Iron, Stainless Steel, Brass |

| Safe for Use With | Water, Oil, Gas, Chemicals |

| Handle Type | Lever, Handwheel, Gear |

| Handle Material | Steel, Aluminum, Plastic |

| Maximum Working Pressure (psi) | Up to 2500 psi |

| Maximum Working Pressure (bar) | Up to 172 bar |

| Operating Pressure | Typically 3 bar |

The Parameter of Fcv Valve

- Type: The FCV Valve is primarily a flow control valve designed to regulate the flow rate of fluids within a system.

- Ball Material: Typically constructed from durable materials like stainless steel to ensure longevity and resistance to corrosion.

- Attachment Type: Available in various attachment types such as flanged or threaded to facilitate easy installation and compatibility with different piping systems.

- Thread Standard: Conforms to industry-standard thread specifications such as ANSI, DIN, or JIS to ensure interchangeability and compatibility.

- Thread Size: Offered in a range of sizes from 1/2 inch to 4 inches, catering to different flow requirements and system configurations.

- Body Material: Constructed from robust materials like cast iron, stainless steel, or brass to withstand high pressures and harsh operating conditions.

- Safe for Use With: Suitable for use with a wide range of fluids including water, oil, gas, and various chemicals, ensuring versatility in application.

- Handle Type: Available with different handle types such as lever, handwheel, or gear for manual operation and control.

- Handle Material: Handles are typically made from durable materials like steel, aluminum, or plastic for ease of operation and longevity.

- Maximum Working Pressure: Capable of withstanding high pressures, with maximum working pressures reaching up to 2500 psi or 172 bar.

- Operating Pressure: Typically operates at a standard pressure of 3 bar, although this may vary depending on specific application requirements.

The Operation Theory of Fcv Valve

- FCV Valve Function: The FCV Valve functions as a flow control device, regulating the flow rate of fluids within a system. By adjusting the valve’s position, users can control the amount of fluid passing through, thus managing the flow rate as required.

- FCV Valve Types: FCV valves come in different types, including globe valves, butterfly valves, and needle valves. Each type operates uniquely to control fluid flow, with variations in design and internal mechanisms to suit specific application needs.

- Multiple FCV Valve Configurations: In some systems, multiple FCV valves may be employed in series or parallel configurations to achieve precise flow control. Series configurations allow for sequential control, while parallel configurations enable redundancy or increased capacity.

The Parameters Table of Fcv Valve

| Parameter | Description |

|---|---|

| Type | Flow Control Valve |

| Body Material | Stainless Steel, Brass, or PVC |

| Ball Material | Stainless Steel or Brass |

| Attachment Type | Flanged, Threaded, or Welded |

| Thread Standard | ANSI, DIN, JIS, or BS |

| Thread Size | Various sizes depending on model |

| Safe for Use With | Water, Oil, Gas, or Chemicals |

| Handle Type | Lever, Handwheel, or Actuator |

| Handle Material | Stainless Steel, Aluminum, or Plastic |

| Maximum Working Pressure psi | Up to 1500 psi |

| Maximum Working Pressure bar | Up to 100 bar |

| Operating Pressure | Typically 3 bar |