Breather Valve

The Application of Breather Valve

Breather valves, including valve cover breather models like valve cover breather filter and LS valve cover breather, are essential components designed to regulate pressure within enclosed systems. These valves allow the release of excess pressure or vacuum buildup, preventing potential damage to equipment or compromising system integrity. Typically installed on equipment such as storage tanks, pipelines, or hydraulic systems, breather valves ensure optimal operation by maintaining pressure levels within safe limits. With a 3 bar Breather Valve, users can rest assured that their systems are protected against overpressure situations, ensuring safety and reliability in various industrial applications.

What Is Breather Valve?

A Breather Valve is a crucial component used to regulate pressure within closed systems. It allows the release of excess pressure or vacuum buildup, safeguarding equipment from potential damage. These valves are commonly installed in storage tanks, pipelines, or hydraulic systems to maintain optimal pressure levels. With their ability to prevent overpressure situations, Breather Valves ensure the safety and reliability of industrial applications.

How Does Breather Valve work?

Breather Valves work by automatically opening to release excess pressure or vacuum within closed systems. When the pressure inside the system exceeds a preset threshold, the valve’s mechanism activates, allowing air or gas to escape. Similarly, when a vacuum develops inside the system, the valve opens to allow ambient air to enter, equalizing the pressure. This continuous regulation of pressure helps prevent damage to equipment and maintains the integrity of the system.

Features of Breather Valve

- Pressure Regulation: Breather Valves feature precise pressure regulation, ensuring that the pressure within the system remains within safe limits.

- Vacuum Relief: These valves are designed to provide vacuum relief, preventing the formation of negative pressure within the system, which could lead to equipment damage.

- Corrosion Resistance: Many Breather Valves are constructed from corrosion-resistant materials such as stainless steel or brass, ensuring durability and longevity in harsh environments.

- Compact Design: They often have a compact design, making them suitable for installation in tight spaces or on equipment with limited clearance.

- Easy Installation: Breather Valves typically feature a straightforward installation process, allowing for quick and hassle-free integration into existing systems.

- Low Maintenance: With minimal moving parts and durable construction, these valves require little maintenance, reducing downtime and operational costs.

- Versatility: They are versatile in application, suitable for use in various industries such as oil and gas, petrochemical, pharmaceutical, and more.

- Temperature Resistance: Many Breather Valves are designed to withstand high temperatures, ensuring reliable performance even in extreme operating conditions.

Advantages of Breather Valve

- Pressure Regulation: Breather valves help maintain optimal pressure levels within closed systems, preventing overpressure situations that could lead to equipment damage or failure.

- Equipment Protection: By releasing excess pressure or vacuum buildup, these valves protect sensitive equipment from potential damage, extending its lifespan and reducing maintenance costs.

- Safety Assurance: Breather valves ensure the safety of personnel and assets by preventing the occurrence of hazardous conditions such as explosions or implosions due to pressure imbalances.

- Environmental Protection: These valves help prevent emissions of harmful gases or vapors into the environment, promoting environmental sustainability and compliance with regulations.

- Process Efficiency: With efficient pressure regulation, breather valves contribute to the smooth operation of industrial processes, minimizing disruptions and maximizing productivity.

The Specifications of Breather Valve

| Specification | Description |

|---|---|

| Type | Pressure/Vacuum Relief Breather Valve |

| Ball Material | Stainless Steel or Brass |

| Attachment Type | Threaded or Flanged |

| Thread Standard | NPT (National Pipe Thread) or BSP (British Standard Pipe) |

| Thread Size | Various sizes available, typically ranging from 1/4″ to 2″ |

| Body Material | Carbon Steel, Stainless Steel, or Aluminum |

| Safe for Use With | Various fluids and gases, including air, steam, water, oil, etc. |

| Handle Type | Typically non-operable (fixed) |

| Handle Material | N/A |

| Maximum Working Pressure psi | Typically ranges from 5 psi to 150 psi |

| Maximum Working Pressure bar | Typically ranges from 0.35 bar to 10 bar |

| Operating Pressure | Set to open at predetermined pressure levels |

The Parameter of Breather Valve

- Type: Breather valves are typically designed as pressure/vacuum relief valves, allowing for the release of excess pressure or vacuum buildup within closed systems.

- Ball Material: The ball inside the valve is commonly made of stainless steel or brass, ensuring durability and resistance to corrosion.

- Attachment Type: These valves can be available in threaded or flanged attachment types, allowing for easy installation in various systems.

- Thread Standard: The thread standard can be NPT (National Pipe Thread) or BSP (British Standard Pipe), depending on the application requirements.

- Thread Size: Various thread sizes are available, typically ranging from 1/4″ to 2″, to accommodate different system configurations.

- Body Material: Breather valves are constructed from materials such as carbon steel, stainless steel, or aluminum, providing strength and compatibility with different operating conditions.

- Safe for Use With: They are suitable for use with various fluids and gases, including air, steam, water, oil, and more.

- Handle Type: Breather valves typically have a non-operable (fixed) handle design, as they are set to open automatically at predetermined pressure levels.

- Handle Material: The handle material may not be applicable as breather valves usually feature non-operable handles.

- Maximum Working Pressure psi: The maximum working pressure typically ranges from 5 psi to 150 psi, depending on the valve’s design and application.

- Maximum Working Pressure bar: The maximum working pressure is typically between 0.35 bar to 10 bar, providing flexibility for various industrial settings.

- Operating Pressure: Breather valves are set to open at specific pressure thresholds, ensuring efficient pressure relief and system protection.

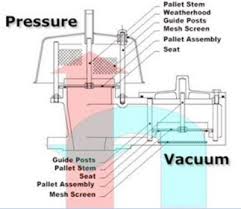

The Operation Theory of Breather Valve

- Pressure Relief: When the pressure within the system exceeds a predetermined threshold, the breather valve opens to release the excess pressure. This prevents overpressurization, which could lead to equipment damage or failure.

- Vacuum Relief: Conversely, when the system experiences negative pressure or vacuum buildup, such as during cooling or fluid withdrawal, the breather valve also opens to allow ambient air to enter the system. This prevents the formation of a vacuum that could impede fluid flow or cause equipment collapse.

- Operation Mechanism: Breather valves typically employ a spring-loaded mechanism or a weighted disc to regulate the opening and closing of the valve. The spring tension or weight is calibrated to the desired pressure or vacuum threshold, ensuring precise control over the relief process.

- Applications: Breather valves are commonly used in various applications, including automotive engines (such as SBC valve cover breathers and valve cover breathers with PCV), fuel tanks, hydraulic systems, and industrial equipment. They play a crucial role in maintaining the integrity and efficiency of these systems by preventing pressure-related issues and ensuring proper ventilation.

The Parameters Table of Breather Valve

Certainly, here’s a parameters table for Breather Valves:

| Parameter | Description |

|---|---|

| Type | Pressure/Vacuum Relief Breather Valve |

| Ball Material | Stainless Steel or Brass |

| Attachment Type | Threaded or Flanged |

| Thread Standard | NPT (National Pipe Thread) or BSP (British Standard Pipe) |

| Thread Size | Various sizes available, typically ranging from 1/4″ to 2″ |

| Body Material | Carbon Steel, Stainless Steel, or Aluminum |

| Safe for Use With | Various fluids and gases, including air, steam, water, oil, etc. |

| Handle Type | Typically non-operable (fixed) |

| Handle Material | N/A |

| Maximum Working Pressure (psi) | Typically ranges from 5 psi to 150 psi |

| Maximum Working Pressure (bar) | Typically ranges from 0.35 bar to 10 bar |

| Operating Pressure | Set to open at predetermined pressure levels |