A Comprehensive Overview of Pressure Relief Valve Types

The Application of Pressure Relief Valve

Pressure Relief Valve, including boiler pressure relief valve, air compressor pressure relief valve, and hydraulic pressure relief valve, plays a crucial role in maintaining safe operating conditions in various systems. These valves are essential components in equipment like boilers, air compressors, and hydraulic systems to prevent overpressure situations that could lead to equipment damage or catastrophic failure. Cameron offers a range of reliable pressure relief valves designed to handle different pressure ranges and fluid types. By automatically releasing excess pressure when it exceeds preset limits, these valves ensure the safety and integrity of industrial processes. Whether it’s safeguarding a boiler system, maintaining optimal pressure in an air compressor, or protecting hydraulic machinery, pressure relief valves are indispensable for efficient and safe operation.

What Are The Types Of Pressure Relief Valve?

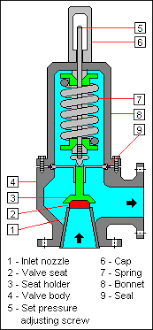

- Safety Relief Valve: These valves are the most common type and are designed to open gradually as pressure increases, relieving excess pressure to prevent equipment damage.

- Pressure Safety Valve (PSV): Similar to safety relief valves, PSVs are designed to open fully at a set pressure to release excess pressure quickly and prevent catastrophic failures.

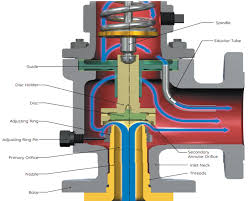

- Pilot-Operated Relief Valve: These valves use a pilot system to control the opening and closing of the valve, providing precise pressure control and handling higher pressure ranges.

- Vacuum Relief Valve: While not technically a “pressure” relief valve, vacuum relief valves are designed to prevent equipment damage by relieving vacuum pressure and preventing collapse or damage to vessels.

- Thermal Relief Valve: These valves open to relieve pressure caused by thermal expansion in pipelines or systems experiencing temperature fluctuations.

- Low-Pressure Relief Valve: Designed for lower pressure applications, these valves provide relief at lower pressure thresholds, such as those found in HVAC systems or low-pressure pipelines.

What Is Pressure Relief Valve?

A Pressure Relief Valve is a safety device designed to automatically release excess pressure from a system to prevent equipment damage or catastrophic failure. Installed in various industrial systems such as boilers, air compressors, and hydraulic machinery, these valves ensure safe operating conditions by opening when pressure exceeds preset limits, allowing fluid to escape until pressure returns to a safe level. Pressure relief valves play a critical role in maintaining system integrity and preventing accidents caused by overpressure situations.

How Does Pressure Relief Valve work?

A Pressure Relief Valve operates by sensing the pressure within a system. When pressure surpasses a predetermined threshold, the valve opens, allowing excess fluid or gas to escape. This action helps reduce pressure, preventing potential damage to equipment or systems. Once pressure returns to a safe level, the valve closes to maintain normal operating conditions. The valve’s mechanism may vary based on the type and application, but the primary function remains consistent: to safeguard against overpressure situations.

Features of Pressure Relief Valve

- Pressure Sensing: Pressure relief valves are equipped with mechanisms to sense changes in pressure within a system.

- Automatic Operation: These valves operate automatically, opening when pressure exceeds a set limit and closing when pressure returns to a safe level.

- Versatility: Available in various types and configurations, pressure relief valves are versatile and adaptable to different applications and pressure ranges.

- Safety: Their primary function is to ensure safety by preventing overpressure situations, protecting equipment and personnel from potential harm.

- Reliable Performance: Pressure relief valves offer reliable performance, designed to withstand harsh operating conditions and provide consistent pressure regulation.

- Adjustability: Many pressure relief valves are adjustable, allowing users to set the pressure threshold according to specific requirements.

- Compatibility: They are compatible with a wide range of fluids and gases, making them suitable for diverse industrial applications.

- Longevity: Constructed from durable materials, pressure relief valves offer longevity and require minimal maintenance, contributing to cost-effectiveness and efficiency.

Advantages of Pressure Relief Valve

- Equipment Protection: Pressure relief valves safeguard equipment from damage caused by excessive pressure, ensuring their longevity and reliability.

- Safety Assurance: They provide a critical safety measure by preventing overpressure situations, reducing the risk of accidents or catastrophic failures.

- Regulatory Compliance: Using pressure relief valves helps industries comply with safety regulations and standards, avoiding potential fines or legal liabilities.

- System Integrity: By maintaining optimal pressure levels, these valves ensure the integrity and efficiency of industrial systems, minimizing downtime and maximizing productivity.

- Cost Savings: Pressure relief valves help prevent costly repairs or replacements of equipment due to pressure-related damage, resulting in long-term cost savings.

- Versatility: With various types and configurations available, pressure relief valves offer versatility, suitable for a wide range of applications and industries.

- Ease of Installation: They are relatively easy to install and integrate into existing systems, minimizing installation time and labor costs.

- Peace of Mind: Knowing that pressure relief valves are in place provides peace of mind to operators and personnel, ensuring a safe working environment.

The Specifications of Pressure Relief Valve

| Specification | Details |

|---|---|

| Type | Pressure Relief Valve |

| Ball Material | Stainless Steel, Brass, Carbon Steel, Alloy |

| Attachment Type | Flanged, Threaded, Welded |

| Thread Standard | NPT, BSP, BSPT, DIN, JIS |

| Thread Size | 1/2 inch to 6 inches (or custom) |

| Body Material | Cast Iron, Stainless Steel, Brass, Aluminum |

| Safe for Use With | Water, Oil, Gas, Steam, Chemicals |

| Handle Type | Lever, Handwheel, Knob |

| Handle Material | Stainless Steel, Aluminum, Plastic |

| Maximum Working Pressure | Up to 5000 psi (345 bar) |

| Operating Pressure | Varies based on specific model and application |

The Parameter of Pressure Relief Valve

- Type: Pressure Relief Valve

- Ball Material: Stainless Steel, Brass, Carbon Steel, Alloy

- Attachment Type: Flanged, Threaded, Welded

- Thread Standard: NPT, BSP, BSPT, DIN, JIS

- Thread Size: 1/2 inch to 6 inches (or custom)

- Body Material: Cast Iron, Stainless Steel, Brass, Aluminum

- Safe for Use With: Water, Oil, Gas, Steam, Chemicals

- Handle Type: Lever, Handwheel, Knob

- Handle Material: Stainless Steel, Aluminum, Plastic

- Maximum Working Pressure: Up to 5000 psi (345 bar)

- Operating Pressure: Varies based on specific model and application