Ball Valve with Electrical Actuator 12inch 600LB A105

The Application of Ball Valve with Electrical Actuator

Cameron, a trusted leader in industrial solutions, offers a wide range of innovative electric valve actuators for precise control and automation. The electric actuated ball valve combines the reliability of a ball valve with the efficiency of an electric valve actuator, providing seamless operation and control in various applications. With electric actuated ball valves, users can remotely control the flow of fluids or gases with precision and ease. These valves are widely used in industries such as oil and gas, water treatment, and chemical processing, where accurate flow control is essential. Trust Cameron for reliable and efficient electric actuated ball valves that meet your operational needs.

What Are The Types Of Ball Valve with Electrical Actuator?

- On/Off Ball Valve with Electrical Actuator: These valves are designed to either fully open or fully close in response to an electrical signal, providing simple on/off control.

- Modulating Ball Valve with Electrical Actuator: Modulating ball valves can adjust the flow rate continuously, allowing for precise control of fluid or gas flow. The electrical actuator modulates the valve position based on the input signal, maintaining the desired flow rate.

- Three-Way Ball Valve with Electrical Actuator: Three-way ball valves have three ports and can divert or mix flow between two different paths. The electrical actuator controls the position of the ball to direct flow as needed.

- Floating Ball Valve with Electrical Actuator: In floating ball valves, the ball is not fixed in position, allowing it to float between the seals. The electrical actuator rotates the ball to open or close the valve, providing reliable sealing.

- Trunnion Ball Valve with Electrical Actuator: Trunnion ball valves have a fixed ball supported by trunnion bearings, enabling higher pressure and larger size applications. The electrical actuator rotates the trunnion-mounted ball to control flow.

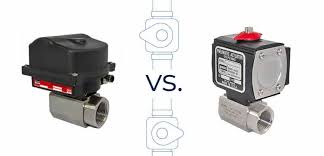

What Is Ball Valve with Electrical Actuator?

A ball valve with electrical actuator is a type of industrial valve equipped with an electrically operated actuator. This actuator is responsible for controlling the position of the valve’s ball, allowing for precise regulation of fluid or gas flow. By receiving electrical signals, the actuator opens or closes the valve, providing efficient and automated flow control. Ball valves with electrical actuators are widely used in various industries, including oil and gas, water treatment, and HVAC systems, where remote operation and precise flow control are essential.

How Does Ball Valve with Electrical Actuator work?

A ball valve with electrical actuator operates by utilizing the electrical actuator to control the position of the valve’s ball. When an electrical signal is received, the actuator rotates the ball either to an open or closed position, allowing or blocking the flow of fluid or gas through the valve. This automated process enables precise and efficient flow control, eliminating the need for manual intervention. Ball valves with electrical actuators offer remote operation capabilities and can be integrated into automated systems for enhanced control and monitoring.

Features of Ball Valve with Electrical Actuator

- Remote Operation: Enables remote control of the valve’s position, allowing for operation from a distance.

- Precision Control: Provides precise regulation of fluid or gas flow, ensuring accurate adjustment according to system requirements.

- Automation: Integrates seamlessly into automated systems, enhancing efficiency and reducing manual intervention.

- Quick Response Time: Offers rapid response to electrical signals, facilitating fast opening and closing of the valve.

- Versatility: Suitable for various applications and industries, including oil and gas, water treatment, and HVAC systems.

- Reliability: Ensures reliable performance over extended periods, minimizing downtime and maintenance requirements.

- Safety: Incorporates fail-safe features to ensure safe operation in critical environments, enhancing system safety.

- Durability: Constructed from robust materials, providing long-lasting durability and resistance to corrosion and wear.

Advantages of Ball Valve with Electrical Actuator

- Efficiency: Offers efficient flow control with automated operation, reducing manual labor and increasing productivity.

- Precision: Provides precise positioning and control of fluid or gas flow, ensuring accurate regulation according to system requirements.

- Flexibility: Allows for remote operation and integration into automated systems, offering flexibility in control options.

- Safety: Incorporates fail-safe features to ensure safe operation, minimizing the risk of accidents or system failures.

- Reliability: Offers reliable performance over extended periods, reducing the likelihood of downtime and maintenance requirements.

- Versatility: Suitable for a wide range of applications and industries, providing versatility in usage scenarios.

- Cost-Effectiveness: Helps optimize resource utilization and operational costs by reducing manual labor and enhancing efficiency.

- Ease of Integration: Integrates easily into existing systems, facilitating seamless implementation and operation.

The Specifications of Ball Valve with Electrical Actuator

| Specification | Details |

|---|---|

| Type | Ball Valve with Electrical Actuator |

| Ball Material | Stainless Steel, Brass, Carbon Steel, PVC |

| Attachment Type | Flanged, Threaded, Welded, Socket Weld |

| Thread Standard | NPT, BSP, BSPT, DIN, JIS, API |

| Thread Size | 1/2 inch to 24 inches (for threaded), 2 inches to 48 inches (for flanged) |

| Body Material | Stainless Steel, Carbon Steel, Cast Iron, PVC |

| Safe for Use With | Water, Oil, Gas, Chemicals, Steam, Air |

| Handle Type | Lever, Handwheel, Gear Operator, Electric Actuator |

| Handle Material | Stainless Steel, Aluminum Alloy, Plastic |

| Maximum Working Pressure | Up to 6000 psi (413.7 bar) |

| Maximum Working Pressure | Up to 10000 psi (689.5 bar) (for high-pressure models) |

| Operating Pressure | Varies based on specific model and application |

The Parameter of Ball Valve with Electrical Actuator

- Type: The Ball Valve with Electrical Actuator combines the functionality of a ball valve with an electrically operated actuator for automated control.

- Ball Material: Available in various materials such as stainless steel, brass, carbon steel, and PVC to suit different applications and fluid compatibility requirements.

- Attachment Type: Can be flanged, threaded, welded, or socket welded, providing flexibility in installation options.

- Thread Standard: Available in NPT, BSP, BSPT, DIN, JIS, and API standards to ensure compatibility with different piping systems.

- Thread Size: Ranges from 1/2 inch to 24 inches for threaded connections and 2 inches to 48 inches for flanged connections, accommodating various pipe sizes.

- Body Material: Constructed from materials like stainless steel, carbon steel, cast iron, or PVC, providing durability and resistance to corrosion.

- Safe for Use With: Suitable for a wide range of fluids, including water, oil, gas, chemicals, steam, and air, depending on the material compatibility.

- Handle Type: Can be equipped with a lever, handwheel, gear operator, or electric actuator for manual or automated operation.

- Handle Material: Available in materials such as stainless steel, aluminum alloy, or plastic, providing options for different operating environments.

- Maximum Working Pressure: Maximum working pressure can range up to 6000 psi (413.7 bar) for standard models and up to 10000 psi (689.5 bar) for high-pressure models, ensuring compatibility with various pressure requirements.

- Operating Pressure: Operating pressure varies based on the specific model and application requirements, providing flexibility for different operating conditions.

The Operation Theory of Ball Valve with Electrical Actuator

The operation theory of a Ball Valve with Electrical Actuator involves the integration of an electric actuator with a traditional ball valve mechanism to facilitate automated control. When an electrical signal is received by the actuator, it initiates a series of actions to rotate the valve’s ball, thereby controlling the flow of fluid or gas. This process is similar to the operation of an electric actuated butterfly valve, where the actuator controls the position of the valve’s disc. The electric actuator can be programmed to open, close, or modulate the valve based on system requirements or input signals. This integration of the electric actuator with the ball valve mechanism allows for remote operation, precise control, and automation of flow processes, making it suitable for a wide range of industrial applications.

The Parameters Table of Ball Valve with Electrical Actuator

| Parameter | Details |

|---|---|

| Type | Ball Valve with Electrical Actuator |

| Ball Material | Stainless Steel, Brass, Carbon Steel, PVC |

| Attachment Type | Flanged, Threaded, Welded, Socket Weld |

| Thread Standard | NPT, BSP, BSPT, DIN, JIS, API |

| Thread Size | 1/2 inch to 24 inches (for threaded), 2 inches to 48 inches (for flanged) |

| Body Material | Stainless Steel, Carbon Steel, Cast Iron, PVC |

| Safe for Use With | Water, Oil, Gas, Chemicals, Steam, Air |

| Handle Type | Lever, Handwheel, Gear Operator, Electric Actuator |

| Handle Material | Stainless Steel, Aluminum Alloy, Plastic |

| Maximum Working Pressure | Up to 6000 psi (413.7 bar) |

| Maximum Working Pressure | Up to 10000 psi (689.5 bar) (for high-pressure models) |

| Operating Pressure | Varies based on specific model and application |