Which Is Better, an Angle Valve or a Ball Valve?

The Application of Angle Valve and Ball Valve

Cameron offers a comprehensive range of valves, including the versatile angle valve and ball valve. Angle valves, also known as angle stop valves, are commonly used in plumbing systems to regulate water flow at precise angles, ideal for tight spaces. On the other hand, CPVC ball valves provide reliable control of fluid flow with their spherical closure mechanism. These valves are widely applied in residential, commercial, and industrial settings, ensuring efficient and precise flow control in various fluid-handling systems. Cameron’s commitment to quality ensures that angle valves and ball valves deliver exceptional performance and durability across diverse applications, making them essential components in fluid control solutions.

What Is Angle Valve and Ball Valve?

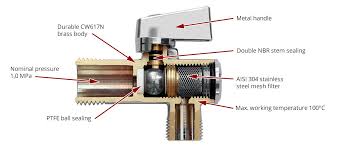

An angle valve is a type of valve designed to regulate the flow of fluid at an angle, typically 90 degrees. It’s commonly used in plumbing systems to control water flow in tight spaces. On the other hand, a ball valve is a valve with a spherical closure mechanism, allowing for precise control of fluid flow. CPVC ball valves are specifically made using chlorinated polyvinyl chloride material, offering excellent resistance to corrosion and chemical damage. Both angle valves and ball valves are essential components in fluid-handling systems across residential, commercial, and industrial applications, ensuring efficient flow control and system integrity.

How Does Angle Valve and Ball Valve work?

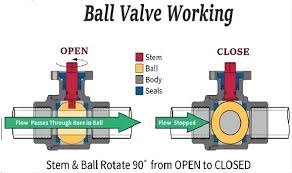

Angle valves control fluid flow by using a rotating handle to open or close a gate inside the valve body, regulating the flow of water at a 90-degree angle. Ball valves work by rotating a spherical closure mechanism (the ball) inside the valve body, allowing or blocking fluid flow through a hole in the ball. When the handle is turned perpendicular to the pipe, the valve is closed, and when parallel, it’s open, providing precise control over flow. CPVC ball valves operate similarly but are specifically constructed using chlorinated polyvinyl chloride material, offering enhanced resistance to corrosion and chemical damage.

Features of Angle Valve and Ball Valve

- Angle Valve:

- Space-saving Design: Compact and angled body design allows for easy installation in tight spaces.

- Precise Flow Control: Enables precise regulation of fluid flow at a 90-degree angle, ensuring optimal performance in plumbing systems.

- Durable Construction: Built with sturdy materials such as brass or stainless steel, ensuring long-term reliability and resistance to corrosion.

- Variety of Applications: Suitable for a wide range of applications, including residential, commercial, and industrial plumbing systems.

- Easy Operation: Features a simple handle-operated mechanism for effortless opening and closing, providing user convenience.

- Ball Valve:

- Versatile Design: Suitable for a variety of fluids, including water, oil, gas, and chemicals, due to its robust construction and versatile materials.

- Quick On/Off Operation: Provides quick and efficient control over fluid flow with a quarter-turn operation, reducing downtime.

- Bubble-tight Seal: Ensures a tight seal when closed, minimizing leakage and enhancing system efficiency.

- Low Maintenance: Requires minimal maintenance thanks to its durable construction and reliable sealing mechanism, reducing overall operational costs.

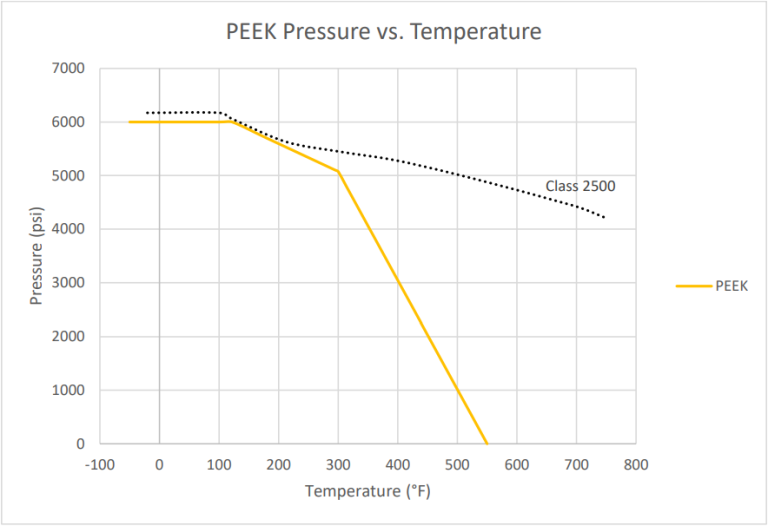

- Wide Temperature Range: Capable of operating in a wide range of temperatures, making it suitable for both hot and cold fluid applications.

Advantages of Angle Valve and Ball Valve

- Angle Valve:

- Space Efficiency: Ideal for use in cramped spaces due to its compact and angled design.

- Precise Flow Control: Offers precise regulation of fluid flow at a 90-degree angle, ensuring optimal performance.

- Versatility: Suitable for various applications in residential, commercial, and industrial settings.

- Durability: Constructed from robust materials like brass or stainless steel, ensuring long-term reliability.

- Ease of Use: Features a simple handle-operated mechanism for effortless operation by users of all skill levels.

- Ball Valve:

- Versatility: Suitable for a wide range of fluids, including water, oil, gas, and chemicals.

- Quick Operation: Provides rapid and efficient control over fluid flow with a quarter-turn operation.

- Leak Prevention: Ensures a tight seal when closed, minimizing the risk of leakage.

- Low Maintenance: Requires minimal maintenance thanks to its durable construction and reliable sealing mechanism.

- Temperature Compatibility: Capable of operating in both hot and cold fluid applications, offering versatility in temperature range.

The Specifications of Angle Valve and Ball Valve

| Specification | Angle Valve | Ball Valve |

|---|---|---|

| Type | Angle Valve | Ball Valve |

| Ball Material | Brass, Stainless Steel | Brass, Stainless Steel, PVC |

| Attachment Type | Threaded, Compression, Flanged | Threaded, Socket Weld, Flanged, Compression |

| Thread Standard | NPT, BSP, BSPT, DIN | NPT, BSP, BSPT, DIN, JIS |

| Thread Size | 1/2 inch to 2 inches | 1/4 inch to 4 inches |

| Body Material | Brass, Stainless Steel, PVC | Brass, Stainless Steel, PVC, Cast Iron, Carbon Steel |

| Safe for Use With | Water, Oil, Gas, Chemicals, Steam, Air | Water, Oil, Gas, Chemicals, Steam, Air |

| Handle Type | Lever, Handwheel, Knob | Lever, Handwheel, Knob, Gear Operator |

| Handle Material | Brass, Stainless Steel, Plastic | Brass, Stainless Steel, Plastic |

| Maximum Working Pressure | Up to 200 psi (13.79 bar) | Up to 1000 psi (68.95 bar) |

| Maximum Working Pressure | Up to 20 bar | Up to 100 bar |

| Operating Pressure | Varies based on specific model and application | Varies based on specific model and application |

The Parameter of Angle Valve and Ball Valve

- Type: The Angle Valve and Ball Valve are two distinct types of valves used for different applications.

- Ball Material: The ball material for Angle Valves typically includes brass or stainless steel, while for Ball Valves, it can be brass, stainless steel, or PVC.

- Attachment Type: Angle Valves can be threaded, compression, or flanged, whereas Ball Valves can be threaded, socket weld, flanged, or compression.

- Thread Standard: Both valves come in various thread standards like NPT, BSP, BSPT, DIN, and JIS, ensuring compatibility with different piping systems.

- Thread Size: Angle Valves range from 1/2 inch to 2 inches in size, while Ball Valves range from 1/4 inch to 4 inches, providing options for different pipe sizes.

- Body Material: Angle Valves are commonly made of brass, stainless steel, or PVC, while Ball Valves can also include cast iron and carbon steel.

- Safe for Use With: Both valves are suitable for use with water, oil, gas, chemicals, steam, and air, offering versatility in various applications.

- Handle Type: Angle Valves feature lever, handwheel, or knob handles, whereas Ball Valves can have lever, handwheel, knob, or gear operator handles.

- Handle Material: Handles for both valves are typically made of brass, stainless steel, or plastic, ensuring durability and ease of operation.

- Maximum Working Pressure: Angle Valves can handle pressures up to 200 psi (13.79 bar), while Ball Valves can handle pressures up to 1000 psi (68.95 bar).

- Maximum Working Pressure: Angle Valves can handle pressures up to 20 bar, while Ball Valves can handle pressures up to 100 bar.

- Operating Pressure: Operating pressure varies based on the specific model and application of each valve, ensuring flexibility in various operating conditions.

The Operation Theory of Angle Valve and Ball Valve

- Angle Valve Operation Theory: Angle valves control fluid flow by using a rotating handle to open or close a gate inside the valve body. This gate regulates the flow of water at a 90-degree angle, making angle valves suitable for use in plumbing systems, particularly in tight spaces where straight-line valves are impractical. The rotating handle allows users to adjust the flow rate precisely, offering flexibility in various applications. The sealing mechanism, typically a rubber washer or O-ring, ensures a tight seal when the valve is closed, preventing leaks and maintaining system integrity.

- Ball Valve Operation Theory: Ball valves operate using a spherical closure mechanism (the ball) inside the valve body. When the handle is turned perpendicular to the pipe, the valve is closed, and when parallel, it’s open. This quarter-turn operation provides quick and efficient control over fluid flow, making ball valves suitable for various applications where rapid on/off operation is required. The ball’s port allows fluid to flow through when open and blocks flow when closed, ensuring precise control over the system. Ball valves can be used with various fluids, including water, oil, gas, and chemicals, making them versatile in different industries.

The Parameters Table of Angle Valve and Ball Valve

| Parameter | Angle Valve | Ball Valve |

|---|---|---|

| Type | Angle Valve | Ball Valve |

| Ball Material | Brass, Stainless Steel | Brass, Stainless Steel, PVC |

| Attachment Type | Threaded, Compression, Flanged | Threaded, Socket Weld, Flanged, Compression |

| Thread Standard | NPT, BSP, BSPT, DIN | NPT, BSP, BSPT, DIN, JIS |

| Thread Size | 1/2 inch to 2 inches | 1/4 inch to 4 inches |

| Body Material | Brass, Stainless Steel, PVC | Brass, Stainless Steel, PVC, Cast Iron, Carbon Steel |

| Safe for Use With | Water, Oil, Gas, Chemicals, Steam, Air | Water, Oil, Gas, Chemicals, Steam, Air |

| Handle Type | Lever, Handwheel, Knob | Lever, Handwheel, Knob, Gear Operator |

| Handle Material | Brass, Stainless Steel, Plastic | Brass, Stainless Steel, Plastic |

| Maximum Working Pressure | Up to 200 psi (13.79 bar) | Up to 1000 psi (68.95 bar) |

| Maximum Working Pressure | Up to 20 bar | Up to 100 bar |

| Operating Pressure | Varies based on specific model and application | Varies based on specific model and application |