You Need to Know About Steam Jacketed Globe Valves

The Application of Steam Jacketed Globe Valves

In the realm of industrial valves, Cameron is recognized for its commitment to quality and innovation. One notable offering is the steam jacketed globe valve, designed to withstand high temperatures and maintain fluid viscosity. Featuring a distinctive jacketed globe valve symbol, this valve is crucial in applications requiring precise flow control and heat management. In China, the heat jacket globe valve finds extensive use in industries such as petrochemicals, where it regulates the flow of viscous fluids under extreme temperatures. Additionally, industries dealing with adhesive substances, such as food processing and pharmaceuticals, benefit from the reliability of globe valves with steam jackets to maintain consistent product quality. With their ability to handle challenging environments, steam jacketed globe valves play a vital role across various industrial sectors, ensuring efficient operations and product integrity.

What Are The Types Of Steam Jacketed Globe Valves?

- Angle Globe Valve with Steam Jacket: This type of globe valve features an angled body design, allowing for easier installation in tight spaces. The steam jacket surrounds the valve body, providing efficient heat transfer to maintain fluid viscosity.

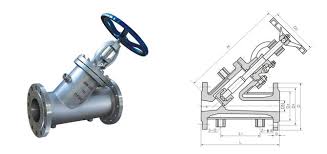

- Y-Pattern Globe Valve with Steam Jacket: Y-pattern globe valves are characterized by their Y-shaped body design, which reduces pressure drop and improves flow characteristics. The steam jacket ensures uniform heating of the valve body and prevents the accumulation of viscous fluids.

- Bellows-Sealed Globe Valve with Steam Jacket: Bellows-sealed globe valves incorporate a bellows seal to prevent leakage and provide additional protection against high temperatures and corrosive fluids. The steam jacket helps to maintain the integrity of the bellows seal and ensures reliable operation in demanding environments.

- Control Globe Valve with Steam Jacket: Control globe valves are designed for precise flow control applications. The steam jacket helps to regulate the temperature of the valve body, ensuring consistent performance and accuracy in controlling fluid flow.

- Cryogenic Globe Valve with Steam Jacket: Cryogenic globe valves are specifically designed to handle extremely low temperatures. The steam jacket provides insulation to prevent freezing of the valve components and maintain fluid flow in cryogenic applications.

What Is Steam Jacketed Globe Valves?

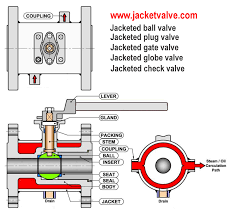

Steam jacketed globe valves are specialized valves designed to regulate the flow of fluids while maintaining a consistent temperature using steam. These valves feature a jacket surrounding the valve body through which steam passes, effectively heating or cooling the valve to prevent fluid from solidifying or becoming too viscous. Commonly used in industries where precise temperature control is critical, such as chemical processing and food manufacturing, steam jacketed globe valves ensure smooth operation and prevent blockages caused by temperature variations.

How Does Steam Jacketed Globe Valves work?

Steam jacketed globe valves work by circulating steam around the valve body through a jacket. As steam flows through the jacket, it transfers heat to the valve, maintaining the desired temperature of the fluid flowing through the valve. This prevents the fluid from solidifying or becoming too viscous, ensuring smooth operation and preventing blockages in the system. The jacketed design effectively controls the temperature of the valve, allowing for precise temperature regulation in various industrial processes.

Features of Steam Jacketed Globe Valves

- Temperature Control: Steam jacketed globe valves provide precise temperature control by regulating the flow of steam around the valve body, ensuring consistent fluid temperature.

- Prevention of Solidification: The jacketed design prevents fluids from solidifying or becoming too viscous, maintaining fluid flow and preventing blockages in the system.

- Versatility: They are suitable for a wide range of fluids, including viscous or corrosive substances, making them versatile for various industrial applications.

- Reduced Maintenance: By maintaining fluid viscosity and preventing blockages, these valves reduce the need for maintenance and downtime, resulting in cost savings.

- Durability: Constructed from robust materials such as stainless steel or alloy, steam jacketed globe valves exhibit high durability and resistance to corrosion, ensuring long-term reliability.

- Safety: The ability to control fluid temperature effectively enhances safety in industrial processes, minimizing the risk of accidents or equipment damage.

- Efficient Heat Transfer: The steam jacket surrounding the valve body ensures efficient heat transfer, optimizing energy usage and reducing operating costs.

Advantages of Steam Jacketed Globe Valves

- Temperature Regulation: Steam jacketed globe valves offer precise control over fluid temperature, ensuring consistent process conditions.

- Prevention of Fluid Solidification: By maintaining the fluid temperature above its solidification point, these valves prevent clogging and blockages in the pipeline.

- Versatility: They are suitable for handling a wide range of fluids, including viscous or sticky substances, making them versatile for various industrial applications.

- Reduced Maintenance: The prevention of solidification and blockages reduces the need for frequent maintenance, minimizing downtime and increasing operational efficiency.

- Enhanced Safety: Consistent fluid temperature prevents sudden changes that could lead to equipment failure or process disruptions, enhancing overall safety.

- Energy Efficiency: Steam jacketed globe valves optimize energy usage by efficiently transferring heat to the fluid, reducing energy consumption and operating costs.

- Longevity: Constructed from durable materials, these valves offer longevity and reliability in demanding industrial environments, minimizing replacement and repair costs.

- Customization Options: They can be customized to meet specific application requirements, including different sizes, materials, and configurations, providing tailored solutions for diverse industries.

The Specifications of Steam Jacketed Globe Valves

| Specification | Details |

|---|---|

| Type | Globe Valve with Steam Jacket |

| Ball Material | Stainless Steel |

| Attachment Type | Flanged |

| Thread Standard | N/A |

| Thread Size | N/A |

| Body Material | Cast Iron, Stainless Steel, Carbon Steel, Alloy Steel, etc. |

| Safe for Use With | Steam, Water, Oil, Chemicals |

| Handle Type | Handwheel |

| Handle Material | Stainless Steel, Cast Iron, Aluminum, etc. |

| Maximum Working Pressure psi | 250 psi |

| Maximum Working Pressure bar | 17.2 bar |

| Operating Pressure | 0-200 psi |

The Installation Steps for Steam Jacketed Globe Valves

- Preparation:

- Gather necessary tools and equipment, including wrenches, bolts, and gaskets.

- Ensure the valve and pipeline are clean and free from debris.

- Positioning:

- Determine the optimal location for the steam jacketed globe valve in the pipeline.

- Ensure sufficient space for valve operation and maintenance access.

- Shut Off Supply:

- Turn off the main supply valve to stop the flow of fluid or steam in the pipeline.

- Release any remaining pressure in the system by opening relief valves.

- Measure and Mark:

- Measure and mark the pipeline at the installation point according to the valve size.

- Use a level to ensure accurate alignment.

- Cut Pipe:

- Cut the pipeline at the marked location using a pipe cutter or saw.

- Ensure the cut is clean and free from burrs or irregularities.

- Prepare Valve and Pipeline:

- Apply pipe sealant or Teflon tape to the threaded ends of the valve and pipeline.

- Install gaskets and bolts as necessary for flanged connections.

- Attach Valve to Pipeline:

- Position the valve in place and align it with the cut ends of the pipeline.

- Securely fasten the valve to the pipeline using bolts or other appropriate fasteners.

- Tighten Connections:

- Use wrenches to tighten the connections between the valve and pipeline.

- Ensure all connections are snug and leak-free.

- Connect Steam Jacket:

- Connect the steam jacket inlet and outlet ports of the valve to the steam supply and return lines, respectively.

- Ensure proper alignment and tight connections to prevent steam leaks.

- Test for Leaks:

- Slowly open the main supply valve to allow fluid or steam into the system.

- Check all connections and joints for leaks using a soapy water solution or leak detector.

- Finalize Installation:

- Once all connections are confirmed to be leak-free, operate the valve to ensure proper functionality.

- Securely anchor the valve to nearby structures or supports if necessary.

- Label the valve for easy identification and future maintenance.

The Operation Theory of Steam Jacketed Globe Valves

- Heat Jacket Globe Valve: Heat jacket globe valves feature a jacket surrounding the valve body. Steam is circulated through this jacket, transferring heat to the valve and maintaining the fluid temperature within the valve at a desired level. This prevents the fluid from solidifying or becoming too viscous, ensuring smooth flow and preventing blockages in the system.

- Jacket Globe Valve: Jacket globe valves function similarly to heat jacket globe valves, with the jacket surrounding the valve body. However, instead of steam, other heating or cooling mediums such as hot water or thermal oil can be circulated through the jacket to regulate the valve’s temperature. This allows for precise temperature control tailored to the specific requirements of the industrial process.

The Parameters Table of Steam Jacketed Globe Valves

| Parameter | Material |

|---|---|

| Valve Body | Cast Iron, Stainless Steel, Carbon Steel, Alloy Steel, etc. |

| Valve Bonnet | Cast Iron, Stainless Steel, Carbon Steel, Alloy Steel, etc. |

| Valve Seat | Stainless Steel, PTFE (Teflon), Graphite, etc. |

| Valve Disc | Stainless Steel, Carbon Steel, Alloy Steel, etc. |

| Stem | Stainless Steel, Alloy Steel, etc. |

| Steam Jacket | Carbon Steel, Stainless Steel, Alloy Steel, etc. |

| Gaskets | Graphite, PTFE (Teflon), Rubber, etc. |

| Bolts/Nuts | Stainless Steel, Carbon Steel, Alloy Steel, etc. |

| Packing | PTFE (Teflon), Graphite, etc. |

| Handwheel | Cast Iron, Stainless Steel, Alloy Steel, etc. |