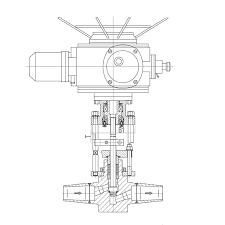

Power Plant Drain Control Valves

The Application of Power Plant Drain Control Valves

Introducing Cameron’s expertise in drainage solutions, our Power Plant Drain Control Valves are engineered to excel in demanding environments. Designed for efficiency and reliability, our Drain Control Valves ensure optimal performance in power generation facilities. With specialized features, including robust construction and precise control, our Power Plant Drain Valves are capable of managing high-pressure and high-temperature conditions effectively. These High-Temperature Drain Valves play a pivotal role in maintaining operational integrity by facilitating safe and efficient drainage processes, contributing to the overall efficiency and safety of power plants.

What Are The Types Of Power Plant Drain Control Valves?

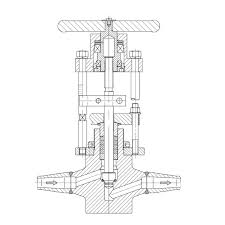

- Gate Valves: These valves provide a tight shut-off and are commonly used for larger diameter drain lines in power plants.

- Ball Valves: Known for their quick operation and simple design, ball valves are suitable for applications requiring frequent operation and tight shut-off.

- Butterfly Valves: Ideal for large flow applications, butterfly valves offer excellent control and can handle high-pressure and high-temperature conditions.

- Globe Valves: Globe valves provide precise control of flow rate and are often used in systems requiring throttling or modulation.

- Diaphragm Valves: These valves offer excellent sealing properties and are suitable for handling corrosive fluids or slurries in power plant drain systems.

What Is Power Plant Drain Control Valves?

Power Plant Drain Control Valves are essential components in power generation facilities, designed to regulate the discharge of water, steam, or other fluids from various systems within the plant. These valves ensure efficient drainage while maintaining operational safety and integrity. They come in various types, including gate valves, ball valves, and butterfly valves, each tailored to specific applications and operating conditions. By facilitating effective fluid management, Power Plant Drain Control Valves contribute to the overall reliability and performance of power plants, enhancing their efficiency and minimizing downtime.

How to Select the Right Power Plant Drain Control Valves?

Selecting the appropriate Power Plant Drain Control Valves involves considering factors such as flow rate, pressure, temperature, fluid characteristics, and system requirements. Assessing the specific application needs and consulting with experts can help in choosing the right valve type, size, material, and features to ensure optimal performance, reliability, and safety in power plant drainage systems. Additionally, evaluating the valve’s compatibility with existing infrastructure and maintenance requirements is crucial for long-term efficiency and cost-effectiveness.

Features of Power Plant Drain Control Valves

- High-Temperature Resistance:

- Valves are designed to withstand elevated temperatures commonly encountered in power plant environments, ensuring reliable operation under extreme conditions.

- Corrosion Resistance:

- Specialized materials and coatings are employed to protect valves from corrosion, prolonging their lifespan and maintaining performance integrity.

- Precise Control:

- Valves offer accurate control over fluid flow rates, allowing for efficient drainage management and system optimization.

- Quick Response:

- Rapid opening and closing mechanisms enable swift response to changing operational requirements, enhancing overall system efficiency.

- Robust Construction:

- Sturdy construction and robust design ensure durability and resilience against mechanical stresses, minimizing downtime and maintenance needs.

- Leak Prevention:

- Tight sealing mechanisms prevent leakage, ensuring environmental compliance and preventing potential hazards.

- Adaptability:

- Valves are available in various sizes, configurations, and actuation methods to suit diverse power plant applications and system requirements.

Advantages and Disadvantages of Power Plant Drain Control Valves

Advantages:

- Efficient Fluid Management:

- Drain control valves ensure efficient drainage, helping to maintain optimal fluid levels and prevent system overflows.

- Enhanced Safety:

- Proper drainage management reduces the risk of equipment damage, accidents, and environmental hazards within power plants.

- Improved System Reliability:

- By regulating fluid flow and preventing blockages, these valves contribute to the overall reliability and longevity of power plant systems.

- Customized Solutions:

- Various types and configurations of drain control valves are available, allowing for tailored solutions to meet specific plant requirements.

- Reduced Downtime:

- Reliable operation and minimal maintenance requirements of these valves help minimize downtime and ensure uninterrupted power generation.

Disadvantages:

- Initial Cost:

- High-quality drain control valves may have an initial upfront cost, although they often provide long-term cost savings through improved efficiency and reduced maintenance.

- Complexity:

- Selecting and installing the right valves for specific applications may require expertise and careful consideration of various factors, adding complexity to the process.

- Potential for Failure:

- Like any mechanical component, drain control valves can experience wear and tear over time, leading to potential failures if not properly maintained.

- Environmental Impact:

- Improperly functioning or malfunctioning drain control valves can lead to environmental pollution or damage if they fail to contain fluids within the plant premises.

- Compatibility Issues:

- Ensuring compatibility with existing infrastructure and systems may pose challenges when selecting and installing drain control valves in power plants.

The Specifications of Power Plant Drain Control Valves

| Specification | Details |

|---|---|

| Type | Ball Valve |

| Ball Material | Stainless Steel |

| Attachment Type | Female Threaded |

| Thread Standard | NPT (National Pipe Thread) |

| Thread Size | 1 inch |

| Body Material | Brass |

| Safe for Use With | Water, Oil, Gas |

| Handle Type | Lever Handle |

| Handle Material | Steel |

| Maximum Working Pressure (psi) | 600 |

| Maximum Working Pressure (bar) | 41.37 |

| Operating Pressure | 0 to 150 psi |

The Installation Steps for Power Plant Drain Control Valves

- Preparation:

- Ensure all necessary tools and equipment are available.

- Review manufacturer’s instructions and safety guidelines.

- Shut down the relevant power plant systems and isolate the drain lines.

- Valve Inspection:

- Check the valve for any visible damage or defects.

- Verify that the valve specifications match the installation requirements.

- Pipe Preparation:

- Clean the pipe ends to remove any dirt, debris, or contaminants.

- Verify that the pipe ends are smooth and free from burrs or irregularities.

- Valve Positioning:

- Position the valve at the desired location along the drain line.

- Ensure proper alignment with the pipe and adjacent components.

- Attachment:

- Use appropriate fittings and connectors to secure the valve to the pipe.

- Tighten all connections securely using the recommended torque values.

- Sealing:

- Apply sealant or thread tape to the threaded connections to ensure a leak-free seal.

- Inspect for any signs of leakage and make adjustments as needed.

- Testing:

- Conduct a pressure test to verify the integrity of the installation.

- Gradually increase the pressure to the operating level and check for leaks.

- Final Checks:

- Confirm that the valve operates smoothly and opens/closes correctly.

- Ensure proper labeling and identification of the valve for future maintenance.

- System Re-Activation:

- Once the installation is complete and verified, re-activate the power plant systems and monitor for any abnormalities.

The Operation Theory of Power Plant Drain Control Valves

- Power Plant Drain Control Valves:

- Operation Theory: These valves regulate the discharge of water, steam, or other fluids from various systems within a power plant. They typically control the flow rate and ensure efficient drainage while maintaining system integrity and safety. The valves open or close in response to signals from the control system, allowing for precise management of fluid levels and pressure within the plant.

- Steam Discharge Valves:

- Operation Theory: Steam discharge valves are designed to release excess steam from boilers, turbines, or other steam-powered equipment. When the steam pressure exceeds the set limit, these valves open automatically to vent steam, preventing overpressure situations. This helps maintain optimal operating conditions and ensures the safety of steam-based systems.

- Wastewater Treatment Valves:

- Operation Theory: Wastewater treatment valves play a crucial role in managing the flow of wastewater within treatment facilities. These valves control the movement of wastewater through various treatment processes such as filtration, sedimentation, and disinfection. By regulating the flow rate and directing wastewater along the treatment path, these valves contribute to the efficient and effective treatment of wastewater, ultimately ensuring environmental compliance and public health protection.

The Parameters Chart of Power Plant Drain Control Valves

| Parameter | Details |

|---|---|

| Valve Type | Gate Valve, Ball Valve, Butterfly Valve, etc. |

| Valve Body Material | Stainless Steel, Carbon Steel, Brass, etc. |

| Valve Seat Material | PTFE (Polytetrafluoroethylene), EPDM, Viton, etc. |

| Valve Trim Material | Stainless Steel, Brass, Bronze, etc. |

| Stem Material | Stainless Steel, Carbon Steel, Alloy Steel, etc. |

| Bonnet Material | Stainless Steel, Carbon Steel, Brass, etc. |

| Seat Ring Material | Stainless Steel, Carbon Steel, Alloy Steel, etc. |

| Disc Material | Stainless Steel, Carbon Steel, Bronze, etc. |

| Actuator Material | Aluminum Alloy, Ductile Iron, Cast Iron, etc. |

| Gasket Material | Graphite, PTFE, Nitrile, etc. |

| Packing Material | PTFE, Graphite, Kevlar, etc. |