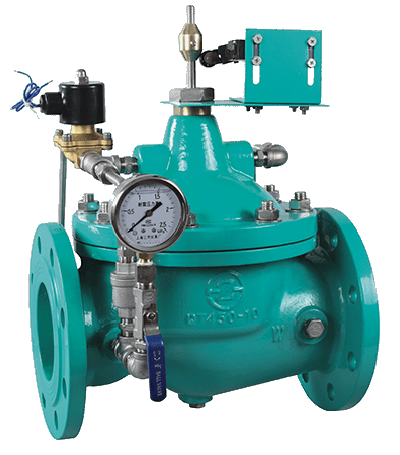

14 Inch Gate Valve 150 LB RF A216 WCB Material BB OS&Y

The Application of 14 Inch Gate Valve

Cameron, a leading manufacturer of industrial valves, offers a wide range of 14 Inch Gate Valve solutions for various applications. These valves are designed to provide reliable flow control and shut-off capabilities, making them a popular choice for industries such as oil and gas, petrochemical, and power generation. The 14 Inch Gate Valve, with its robust construction and precise control, is an ideal choice for applications that require a balance between cost-effectiveness and performance. For those seeking a 14 Inch Gate Valve Price that fits their budget, Cameron’s offerings provide a competitive option without compromising quality. Additionally, the company’s 14 Inch Knife Gate Valve line caters to applications where tight shut-off and abrasive media handling are essential, further demonstrating Cameron’s commitment to delivering diverse and reliable valve solutions.

What Are The Types Of 14 Inch Gate Valve?

1. Wedge Gate Valve:

- This is the most common type of gate valve, featuring a wedge-shaped disc that seals against the valve body when closed.

- It provides a tight shut-off and is suitable for a wide range of applications, including water, oil, gas, and steam services.

2. Parallel Slide Gate Valve:

- In this design, the gate moves parallel to the valve body, allowing for a reduced overall valve size.

- Parallel slide gate valves are often used in applications with limited space or where a compact valve is required.

3. Solid Wedge Gate Valve:

- The solid wedge gate valve has a one-piece, solid wedge-shaped disc that provides excellent sealing performance.

- It is commonly used in high-pressure and high-temperature applications where a reliable shut-off is crucial.

4. Flexible Wedge Gate Valve:

- This type of gate valve has a flexible wedge that can conform to the valve body, improving the sealing performance.

- Flexible wedge gate valves are suitable for applications with varying operating conditions or when a tighter seal is required.

5. Knife Gate Valve:

- The 14 Inch Knife Gate Valve features a knife-like gate that slides perpendicular to the flow, providing a tight shut-off and the ability to handle slurries and abrasive media.

- Knife gate valves are commonly used in the paper, mining, and wastewater industries.

Regardless of the specific type, 14 Inch Gate Valve from manufacturers like Cameron are designed to deliver reliable performance, long service life, and cost-effective solutions for various industrial applications.

What Is 14 Inch Gate Valve?

A 14 Inch Gate Valve is a type of industrial valve that is widely used to control the flow of fluids, gases, and slurries in various applications. This valve is characterized by its circular body and a movable gate or disc that can be raised or lowered to allow or restrict the flow through the valve. The 14 Inch dimension refers to the nominal pipe size, which is a common size used in many industrial and commercial systems. Gate Valves are known for their ability to provide a tight shut-off, making them suitable for isolation and on/off control in applications such as oil and gas, power generation, water treatment, and chemical processing. Their robust construction and reliable performance make 14 Inch Gate Valves an essential component in many industrial and infrastructure projects.

How to Select the Right 14 Inch Gate Valve?

- Pressure Rating: Determine the maximum operating pressure of the system and select a valve with a suitable pressure rating, such as ANSI Class 150 or Class 300.

- Temperature Range: Ensure the valve can withstand the expected temperature range of the media flowing through the system, as gate valves have varying temperature limitations.

- Material Compatibility: Choose a valve material that is compatible with the media being handled, such as stainless steel, carbon steel, or specialty alloys, to prevent corrosion or chemical attack.

- Valve Body Design: Consider the valve body design, such as bolted or welded construction, to match the installation requirements and system configuration.

- Actuation Method: Decide on the appropriate actuation method, whether manual, electric, pneumatic, or hydraulic, based on the level of automation and control required.

- End Connections: Select the appropriate end connections, such as flanged, threaded, or butt-weld, to seamlessly integrate the 14 Inch Gate Valve into the existing piping system.

- Regulatory Compliance: Ensure the valve meets any relevant industry standards, certifications, or regulations applicable to your specific application.

Features of 14 Inch Gate Valve

Pressure Rating:

- 14 Inch Gate Valves are available in a range of pressure ratings, such as ANSI Class 150 and Class 300, to withstand the specific operating pressures of the system.

Flow Capabilities:

- The large 14 Inch size allows for high flow rates, making these valves suitable for applications that require substantial flow capacity.

Tight Shut-off:

- The design of Gate Valves ensures a tight shut-off when the valve is in the closed position, providing reliable isolation and control of the flow.

Versatile Materials:

- 14 Inch Gate Valves can be manufactured using a variety of materials, including stainless steel, carbon steel, and specialty alloys, to suit different chemical and environmental conditions.

Actuation Options:

- These valves can be equipped with manual, electric, pneumatic, or hydraulic actuation, allowing for flexible integration into automated control systems.

Rugged Construction:

- The robust construction of 14 Inch Gate Valves ensures long-lasting performance and reliability, even in demanding industrial environments.

Ease of Maintenance:

- Many 14 Inch Gate Valve designs feature user-friendly maintenance features, such as accessible packing glands and replaceable components, simplifying servicing and repairs.

Advantages and Disadvantages of 14 Inch Gate Valve

Advantages of 14 Inch Gate Valve:

Large Flow Capacity:

- The 14 Inch size allows for high flow rates, making these valves suitable for applications that require substantial flow handling.

Tight Shut-off:

- Gate Valves provide a reliable and tight shut-off when the valve is in the closed position, ensuring effective isolation of the flow.

Versatility:

- These valves can be manufactured using a variety of materials to suit different chemical, temperature, and pressure requirements.

Robust Construction:

- The rugged design of 14 Inch Gate Valves ensures long-lasting performance and reliability, even in demanding industrial environments.

Ease of Maintenance:

- Many 14 Inch Gate Valve designs feature user-friendly maintenance features, simplifying servicing and repairs.

Disadvantages of 14 Inch Gate Valve:

Limited Throttling Capabilities:

- Gate Valves are primarily designed for on/off control and are not well-suited for precise flow throttling applications.

Potential for Erosion:

- In some applications with high-velocity fluids or abrasive media, the 14 Inch Gate Valve may be susceptible to erosion, which can compromise its performance over time.

Larger Installation Space:

- The 14 Inch size of these valves requires more installation space compared to smaller valve sizes, which may be a consideration in confined spaces.

Higher Cost:

- Larger 14 Inch Gate Valves generally have a higher initial cost compared to smaller valve sizes, which can be a factor in budget-constrained projects.

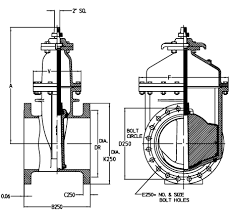

The Specifications of 14 Inch Gate Valve

| Specification | Details |

|---|---|

| Type | Solid Wedge Gate Valve |

| Ball Material | N/A (Gate Valve) |

| Attachment Type | Flanged |

| Thread Standard | N/A |

| Thread Size | N/A |

| Body Material | Carbon Steel |

| Safe for Use With | Water, Oil, Gas, Steam |

| Handle Type | Handwheel |

| Handle Material | Carbon Steel |

| Maximum Working Pressure (psi) | 285 |

| Maximum Working Pressure (bar) | 19.7 |

| Operating Pressure | 150 – 300 ANSI Class |

The Installation Steps for 14 Inch Gate Valve

Step 1: Prepare the Piping

- Ensure the piping system is properly aligned and supported to prevent any strain on the valve.

- Clean the pipe ends and remove any debris, burrs, or contaminants.

Step 2: Position the Valve

- Carefully lift and place the 14 Inch Gate Valve in the desired location within the piping system.

- Align the valve’s flanges with the corresponding pipe flanges.

Step 3: Secure the Valve

- Insert the appropriate flange bolts through the valve and pipe flanges.

- Tighten the bolts in a star or crisscross pattern to the recommended torque specification.

Step 4: Check the Valve Orientation

- Ensure the valve’s flow direction matches the intended flow of the system.

- Verify that the valve’s handwheel or actuator is oriented for easy access and operation.

Step 5: Connect Accessories (if applicable)

- If the valve is equipped with additional accessories, such as limit switches or position indicators, connect them according to the manufacturer’s instructions.

Step 6: Perform a Leak Test

- Pressurize the system and check for any leaks around the valve’s body, flanges, or packing gland.

- Tighten the packing gland or replace the packing material if necessary to eliminate any leaks.

Step 7: Operate the Valve

- Slowly open and close the valve to ensure smooth operation and proper sealing.

- Adjust the packing gland tension if required to maintain the desired level of stem friction.

Step 8: Document the Installation

- Record the valve’s installation details, including the date, location, and any relevant system information.

- Keep the documentation for future reference and maintenance purposes.

The Operation Theory of 14 Inch Gate Valve

Operation Theory of 14 Inch Gate Valve:

The operation of a 14 Inch Gate Valve is based on the principle of using a movable gate or wedge to control the flow of fluid through the valve.

When the valve is in the open position, the gate is fully retracted, allowing the fluid to flow freely through the valve’s full-bore opening. As the handwheel or actuator is turned, the gate moves perpendicular to the flow direction, gradually closing off the passage and restricting the flow.

In the fully closed position, the gate forms a tight seal against the valve’s seats, effectively shutting off the flow. This on/off control mechanism makes gate valves well-suited for isolating and regulating the flow in piping systems.

14 Inch Knife Gate Valve 125 RF:

A 14 Inch Knife Gate Valve with a 125 RF (Raised Face) flange connection is designed to provide complete shut-off and isolation in pipeline applications. The knife gate design allows for a full-bore opening, enabling high flow capacity. The 125 RF flange facilitates a reliable seal between the valve and the connected piping.

14 Inch Walworth Gate Valves:

Walworth Gate Valves are a specific manufacturer of gate valves, known for their robust construction and reliable performance. The 14 Inch Walworth Gate Valve features a solid wedge design, similar to the general operation theory described earlier. These valves are often used in industrial applications, such as oil and gas, power generation, and water treatment, where dependable isolation and flow control are required.

The key similarities across these 14 Inch valve types are the gate-based flow control mechanism and the large size, which enables high flow capacity. The specific design features, such as the knife gate or Walworth construction, provide variations in performance characteristics to meet the demands of different applications.