The GB Wedge Gate Valve

The Application of Classification of GB Wedge Gate Valve

The Heavy Duty Wedge Gate Valve from GB is a robust and reliable valve solution for demanding industrial applications. Its Structure of Pipeline Wedge Gate Valve features a sturdy design that can withstand high pressure and temperature conditions, making it an ideal choice for pipeline systems. The High Temperature Resistant Wedge Gate Valve from GB is engineered to operate effectively even in harsh environments, ensuring uninterrupted flow control for critical processes. Backed by the renowned Cameron brand, GB’s Wedge Gate Valves are widely used across various industries, including oil and gas, petrochemical, and power generation, where reliable and long-lasting valve performance is paramount.

6″ ball valve

fishplate welding

What Are The Types Of GB Wedge Gate Valve?

- Standard Wedge Gate Valve: This is the basic design, featuring a solid wedge that seals against the valve seats to control the flow.

- Slab Gate Valve: Instead of a solid wedge, this type uses a flexible slab-like gate that conforms to the valve seats for improved sealing.

- Parallel Slide Gate Valve: In this design, the gate moves parallel to the valve body, allowing for full bore flow when fully open.

- Expanding Gate Valve: The gate on this valve expands outward to create a tight seal against the seats, providing enhanced shut-off capabilities.

- Double Disk Gate Valve: This valve uses two independent disks that move together to open and close the flow, offering reliable bi-directional shutoff.

- Knife Gate Valve: Featuring a knife-like gate, this type is well-suited for handling slurries, liquids with solids, and other dirty fluids.

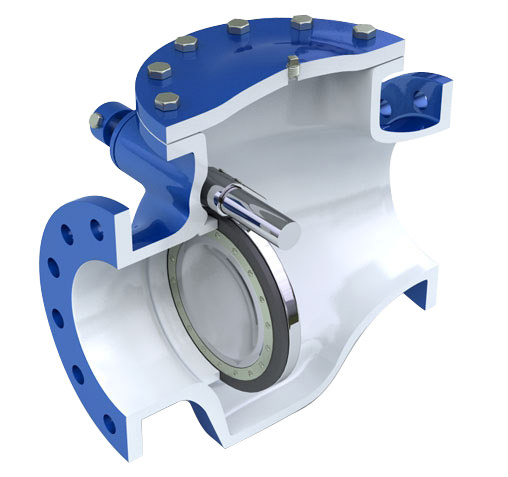

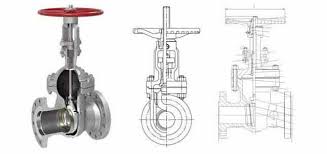

What Is GB Wedge Gate Valve?

A GB Wedge Gate Valve is a versatile and widely-used industrial valve designed to provide reliable flow control and isolation in a variety of applications. The key feature of the GB Wedge Gate Valve is its wedge-shaped gate, which seals against the valve seats to stop or regulate the flow of fluids, gases, or slurries. The robust construction and tight sealing capabilities of these valves make them a popular choice in industries like oil and gas, power generation, and chemical processing, where dependable performance and long service life are essential. GB’s extensive experience in valve engineering ensures that their Wedge Gate Valve lineup offers superior quality, innovative features, and compliance with industry standards, making them a trusted solution for critical flow control requirements.

How to Select the Right GB Wedge Gate Valve?

Fluid Characteristics: Identify the properties of the fluid, such as viscosity, corrosiveness, and the presence of solids, to ensure the valve materials and design are compatible. Pressure and Temperature Ratings: Match the valve’s pressure and temperature capabilities to the expected operating conditions to prevent leaks or damage. Size and End Connections: Ensure the valve size and end connection type (e.g., flanged, threaded) are compatible with the pipeline or equipment. Service Requirements: Determine the level of flow control, shutoff, and isolation needed, and select the appropriate valve type (e.g., standard wedge, parallel slide, expanding gate). By carefully evaluating these parameters, you can select the GB Wedge Gate Valve that will provide reliable and efficient performance for your specific application.

Features of GB Wedge Gate Valve

Robust Construction:

The GB Wedge Gate Valve features a heavy-duty design with sturdy body and trim materials to withstand demanding operating conditions.

Reliable Sealing:

The unique wedge-shaped gate creates a tight seal against the valve seats, ensuring effective flow control and bubble-tight shutoff.

Bi-Directional Sealing:

Many GB Wedge Gate Valve models offer the capability to seal in both directions, providing enhanced flexibility and safety.

Reduced Maintenance:

The simplified design and high-quality components of GB Wedge Gate Valves contribute to reduced maintenance requirements and extended service life.

Compliance with Standards:

GB’s Wedge Gate Valves are engineered to comply with industry standards, ensuring compatibility and safe operation.

Customization Options:

GB offers a range of customization options, allowing users to tailor the valve to specific application needs.

Proven Performance:

With decades of experience in valve manufacturing, GB Wedge Gate Valves are trusted for their reliable and consistent performance.

The Specifications of GB Wedge Gate Valve

| Specification | Details |

|---|---|

| Type | Standard Wedge Gate Valve |

| Ball Material | Stainless Steel |

| Attachment Type | Flanged |

| Thread Standard | ANSI B16.5 |

| Thread Size | 2″ |

| Body Material | Cast Carbon Steel |

| Safe for Use With | Oil, Gas, Water, Steam, Chemicals |

| Handle Type | Handwheel |

| Handle Material | Carbon Steel |

| Maximum Working Pressure (psi) | 600 |

| Maximum Working Pressure (bar) | 41 |

| Operating Pressure | Up to 600 psi (41 bar) |

The Installation Steps for GB Wedge Gate Valve

1. Site Preparation:

Ensure the installation site is clean, free of any debris, and provides adequate space for valve placement and maintenance access.

2. Pipeline Alignment:

Verify that the pipeline is properly aligned and supports are in place to prevent stress on the valve body.

3. Valve Orientation:

Determine the correct orientation of the valve based on the flow direction and accessibility requirements.

4. Flange Connection:

Align the valve flanges with the corresponding pipeline flanges and use the appropriate gaskets, bolts, and nuts to secure the connection.

5. Tightening Sequence:

Tighten the flange bolts in a star or crisscross pattern to ensure an even distribution of force and a proper seal.

6. Valve Stem Orientation:

Adjust the valve stem position to the desired open or closed configuration, depending on the application requirements.

7. Actuator Installation (if applicable):

If the valve is equipped with an actuator, carefully mount and connect the actuator according to the manufacturer’s instructions.

8. Leak Testing:

Perform a thorough leak test on the installed valve and connections to ensure there are no fluid or gas leaks.

9. Operational Checks:

Cycle the valve through its full range of motion to verify smooth operation and proper sealing.

10. Documentation:

Maintain detailed records of the installation, including the date, valve specifications, and any notable observations.

The Operation Theory of GB Wedge Gate Valve

GB Wedge Gate Valve Operation Theory:

The key operating principle of the GB Wedge Gate Valve is the wedge-shaped gate that moves perpendicular to the pipeline flow. When the valve is opened, the wedge retracts, allowing full, unrestricted flow. When closed, the wedge is driven into the valve seats, creating a tight seal that stops the flow. This simple, yet effective design provides reliable flow control and positive shutoff capabilities.

Industrial Wedge Gate Valve Operation Theory:

Industrial Wedge Gate Valves operate on a similar principle, but are typically designed with heavier-duty components to withstand the demands of industrial applications. The robust construction, including reinforced body and trim materials, enables these valves to handle higher pressures, temperatures, and more aggressive media compared to standard commercial-grade valves.

Corrosion Resistant Wedge Gate Valve Operation Theory:

Corrosion Resistant Wedge Gate Valves incorporate specialized materials, such as exotic alloys or polymer coatings, to provide enhanced corrosion protection. This allows them to be used in applications involving corrosive fluids, chemicals, or environments where standard carbon steel valves would quickly deteriorate. The operating mechanism remains the same wedge-and-seat sealing design, but with materials selected to maintain integrity and performance in harsh conditions.