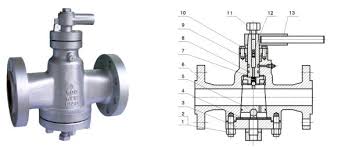

Inverted Pressure Balance Lubricated Plug Valve 2 inch 600 LB

Key Specifications / Features

Model No.: H44H Hits: 27

China Check Valve manufacturer JONLOO supplies Swing Check Valve 6inch 1500LB Bolted Bonnet, and the valve is made according to BS1868 / API 6D.

The Application of Lubricated Plug Valve

Cameron’s Lubricated Plug Valves are a versatile solution for a wide range of industrial applications that require reliable flow control and efficient operation. These valves feature a plug valve lubricant that reduces friction and wear, ensuring smooth and effortless actuation. The lubricated plug valve design allows for a tight seal against leakage, making them an excellent choice for applications that involve hazardous or corrosive fluids. Cameron’s expertise in valve engineering ensures that these valves deliver superior performance and durability, making them a trusted choice for industries such as oil and gas, petrochemical, and power generation, where dependable flow control is of utmost importance.

What Are The Types Of Lubricated Plug Valve ?

Eccentric Plug Valves: These valves feature an offset or eccentric plug design that provides a tight seal and reduces the torque required for operation. The eccentric motion helps to wipe the plug face clean, improving long-term reliability.

Resilient Seated Plug Valves: These valves utilize a resilient seating material, such as Teflon or rubber, to create a tight seal against the plug face. The resilient seat helps to accommodate surface irregularities and provide a reliable shut-off.

Lubricated Tapered Plug Valves: Tapered plug valves use a conical plug that tapers to fit into a matching tapered seat. The plug valve lubricant allows the plug to rotate smoothly while maintaining a tight seal.

Lubricated Cylindrical Plug Valves: Cylindrical plug valves have a straight, cylindrical plug that rotates within a closely fitted body bore. The plug valve lubricant helps to reduce friction and wear in this design.

Cameron, a leading manufacturer of industrial valves, offers a wide range of lubricated plug valve options to meet the diverse needs of various industries, ensuring reliable flow control and efficient operation.

What Is Lubricated Plug Valve ?

Lubricated Plug Valves are a type of industrial valve that use a lubricant to facilitate the smooth rotation of a tapered or cylindrical plug within a closely fitting valve body. The plug valve lubricant creates a low-friction interface between the plug and the valve seat, allowing for effortless actuation and a tight, leak-resistant seal. This design feature makes lubricated plug valves well-suited for applications that involve viscous, abrasive, or corrosive fluids, where traditional valve designs may struggle to maintain reliable performance over time. Cameron, a renowned manufacturer of industrial valves, offers a comprehensive range of lubricated plug valve solutions to meet the diverse needs of industries such as oil and gas, petrochemical, and power generation.

How to Select the Right Lubricated Plug Valve ?

When selecting the right Lubricated Plug Valve for an application, there are several key factors to consider. Flow rate, pressure, temperature, and the characteristics of the fluid being handled are all important parameters that will determine the appropriate valve size, material, and design. Additionally, the valve’s intended service and the required actuation method (manual, pneumatic, or electric) should be evaluated. Cameron recommends carefully reviewing the application requirements to ensure the selected lubricated plug valve can reliably and efficiently meet the system’s needs, while also considering factors such as maintenance requirements and cost-effectiveness. By taking a comprehensive approach to valve selection, users can ensure the optimal performance and longevity of their lubricated plug valve installation.

Features of Lubricated Plug Valve

Tight Seal:

Lubricated Plug Valves utilize a precisely fitted plug and valve body design, along with a plug valve lubricant, to create a tight, leak-resistant seal that prevents fluid from bypassing the valve.

Smooth Operation:

The plug valve lubricant reduces friction and wear, allowing the plug to rotate smoothly and effortlessly, even in applications with viscous or abrasive fluids.

Versatility:

Lubricated Plug Valves are available in a variety of materials, sizes, and configurations to suit diverse industrial applications, from oil and gas to chemical processing.

Corrosion Resistance:

The strategic use of corrosion-resistant materials in the valve construction helps to ensure long-term reliability and performance, even in harsh environments.

Reduced Maintenance:

The self-lubricating nature of lubricated plug valves minimizes the need for frequent maintenance, resulting in lower operating costs and downtime.

Compact Design:

The simple, streamlined design of lubricated plug valves allows for a compact footprint, making them suitable for space-constrained installations.

Advantages and Disadvantages of Lubricated Plug Valve

Advantages of Lubricated Plug Valves:

Tight Sealing: The lubricant-assisted design of lubricated plug valves provides a reliable, leak-resistant seal, making them suitable for handling hazardous or sensitive fluids.

Smooth Operation: The plug valve lubricant reduces friction and torque, allowing for easy and effortless valve actuation, even with viscous or abrasive fluids.

Corrosion Resistance: The use of corrosion-resistant materials in the valve construction helps to extend the service life in harsh environments.

Low Maintenance: The self-lubricating nature of lubricated plug valves reduces the need for frequent maintenance, leading to lower operating costs and improved reliability.

Compact Design: The simple and streamlined design of lubricated plug valves allows for a small footprint, making them suitable for space-constrained installations.

Disadvantages of Lubricated Plug Valves:

Limited Flow Capacity: Compared to other valve types, lubricated plug valves may have a lower maximum flow capacity due to their design limitations.

Potential Leakage: Over time, the plug valve lubricant may degrade or be washed away, leading to potential leakage if the seal is not maintained.

Specialized Maintenance: Proper maintenance of the plug valve lubricant and sealing components requires specialized knowledge and expertise.

Temperature Limitations: The performance of the plug valve lubricant may be affected by extreme temperature conditions, limiting the valve’s suitability for certain applications.

The Specifications of Lubricated Plug Valve

| Specification | Details |

|---|---|

| Type | Lubricated Tapered Plug Valve |

| Ball Material | 316 Stainless Steel |

| Attachment Type | Flanged |

| Thread Standard | ANSI B16.5 |

| Thread Size | 2 inch |

| Body Material | Carbon Steel |

| Safe for Use With | Oil, Gas, Water, Chemicals |

| Handle Type | Lever |

| Handle Material | Aluminum |

| Maximum Working Pressure (psi) | 285 |

| Maximum Working Pressure (bar) | 19.7 |

| Operating Pressure | 0-285 psi (0-19.7 bar) |