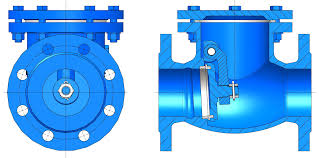

Swing Check Valve 6inch 1500LB Bolted Bonnet

Key Specifications / Features

Model No.: X47W Hits: 44

China Plug Valve Manufacturer Jonloo supplies Inverted Pressure Balance Lubricated Plug Valve. It is applicable to various industries such as petroleum, chemical industry, pharmacy, chemical fertilizer, power industry, etc.

The Application of Swing Check Valve

Cameron, a renowned manufacturer of industrial valves, offers a diverse range of swing check valves to meet the demands of various industries. These valves are designed to allow fluid flow in one direction while preventing reverse flow, making them essential components in piping systems. Cameron’s product line includes PVC swing check valves, 2-inch swing check valves, and 3/4-inch swing check valves, catering to a wide range of applications, from water treatment to HVAC systems. These valves are known for their reliable performance, easy installation, and low maintenance requirements, making them a popular choice for engineers and contractors seeking efficient flow control solutions.

What Are The Types Of Swing Check Valve?

Conventional Swing Check Valve:

This is the most common type of swing check valve. It features a hinged disc that swings open to allow forward flow and closes to prevent reverse flow.

Silent Check Valve:

Also known as a “non-slam” or “noiseless” check valve, the silent check valve uses a spring-loaded disc or piston to provide a gentler, quieter closure, reducing the potential for water hammer.

Wafer Style Check Valve:

The wafer style check valve is a compact, lightweight design that can be installed between flanges, making it a space-saving solution for confined spaces.

Tilting Disc Check Valve:

The tilting disc check valve has a disc that tilts open during forward flow, allowing for a more streamlined, lower resistance path compared to a standard swing check valve.

Dual Plate Check Valve:

This design features two hinged plates that open and close independently, providing redundancy and increased reliability in critical applications.

Ball Check Valve:

Instead of a hinged disc, the ball check valve uses a spherical ball that rolls to open and close the valve, offering a simple and compact solution.

What Is Swing Check Valve?

A Swing Check Valve is a type of check valve that allows fluid to flow in one direction while automatically preventing reverse flow. The valve’s main component is a hinged disc that is pushed open by the forward flow of the fluid, allowing it to pass through. When the fluid attempts to flow in the opposite direction, the disc swings closed, creating a tight seal and preventing backflow. This simple yet effective design makes swing check valves a widely used solution for maintaining the proper flow direction in piping systems, protecting equipment, and ensuring the safety and reliability of various industrial, commercial, and municipal applications. Cameron, a leading manufacturer of industrial valves, offers a comprehensive range of swing check valve types to meet the diverse needs of customers across multiple industries.

How to Select the Right Swing Check Valve?

Flow Direction: Determine the direction of the intended fluid flow, as swing check valves are designed to allow flow in only one direction.

Fluid Characteristics: Consider the properties of the fluid, such as temperature, pressure, and chemical composition, to ensure compatibility with the valve materials.

Size and Connections: Match the valve size and connection type (e.g., flanged, threaded) to the dimensions of your piping system.

Installation Requirements: Evaluate the available space and orientation requirements for the valve, as swing check valves may have specific installation guidelines.

Performance Needs: Assess the desired flow rate, pressure drop, and noise level, and select a valve that meets your system’s performance requirements.

Features of Swing Check Valve

Simplicity:

The Swing Check Valve design is inherently simple, featuring a hinged disc that opens and closes in response to the flow direction, requiring minimal moving parts and maintenance.

Reliability:

The robust construction and tight sealing of swing check valves ensure reliable operation, making them a preferred choice for applications where flow reversal can cause damage or disruption.

Versatility:

Swing Check Valves are available in a wide range of materials, sizes, and configurations to accommodate diverse fluid types, system pressures, and installation requirements.

Compact Design:

The streamlined shape and lightweight construction of swing check valves allow for easy integration into piping systems, even in confined spaces.

Low Maintenance:

With no external power source or control mechanism required, swing check valves operate automatically and require little to no maintenance, reducing operational costs.

Cameron’s Expertise:

As a leading manufacturer, Cameron offers a comprehensive selection of swing check valves that incorporate these features, providing reliable and efficient flow control solutions for various industries.

Advantages and Disadvantages of Swing Check Valve

Advantages of Swing Check Valve:

Cost-Effective:

The simple design and minimal moving parts of Swing Check Valves make them a cost-effective solution for flow control applications.

Automatic Operation:

The self-actuating mechanism of Swing Check Valves allows for automatic opening and closing, eliminating the need for external power or control systems.

Compact Size:

The compact and lightweight construction of Swing Check Valves allows for easy installation in confined spaces.

Versatile Application:

Swing Check Valves can be used in a wide range of industries and applications, from water treatment to HVAC systems.

Low Maintenance:

With no external moving parts, Swing Check Valves require minimal maintenance, reducing operational costs.

Disadvantages of Swing Check Valve:

Limited Flow Capacity:

Compared to other valve types, Swing Check Valves may have a lower maximum flow capacity, which can be a limitation in high-flow applications.

Potential for Water Hammer:

The rapid closure of the valve disc in Swing Check Valves can create water hammer, which can potentially damage the valve or the piping system.

Sensitivity to Debris:

The hinged disc in Swing Check Valves can be susceptible to malfunction or sticking if exposed to high levels of debris or particulates in the fluid stream.

Restricted Installation Orientation:

Swing Check Valves typically require specific installation orientations, which can limit their application in certain system configurations.

The Specifications of Swing Check Valve

| Specification | Details |

|---|---|

| Type | Conventional Swing Check Valve |

| Ball Material | Cast Iron |

| Attachment Type | Flanged |

| Thread Standard | ANSI B16.5 |

| Thread Size | 4 inch |

| Body Material | Cast Iron |

| Safe for Use With | Water, Oil, Gas |

| Handle Type | N/A (No Handle) |

| Handle Material | N/A |

| Maximum Working Pressure | 200 psi |

| Maximum Working Pressure | 13.8 bar |

| Operating Pressure | 150 psi |