What Is A Cooling Tower Isolation Valve

The Application of Cooling Tower Isolation Valve

Introducing the Rotork Cooling Tower Isolation Valve, an essential component for efficient cooling tower systems. This valve serves as a reliable isolation valve for shower, crucial for regulating water flow and temperature. Installed at the shower isolating valve location, it effectively controls water supply to cooling towers, preventing unnecessary wastage and ensuring optimal performance.

The Cooling Tower Isolation Valve by Rotork combines robust construction with precise engineering, guaranteeing seamless operation even in demanding conditions. Whether it’s for routine maintenance or emergency shutdowns, this valve provides dependable isolation, safeguarding cooling tower integrity and prolonging equipment lifespan.

With its proven reliability and versatility, the Rotork Cooling Tower Isolation Valve stands as a trusted solution for cooling tower applications, offering peace of mind and efficiency in water management.

What Is Cooling Tower Isolation Valve?

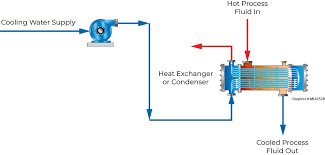

The Cooling Tower Isolation Valve is a vital component in cooling tower systems, designed to regulate water flow and temperature. It acts as a reliable barrier, allowing for precise control over water supply to cooling towers. This isolation valve ensures efficient operation and maintenance, contributing to the overall performance and longevity of cooling tower equipment.

How Does Cooling Tower Isolation Valve work?

The Cooling Tower Isolation Valve operates by controlling the flow of water to cooling towers. When in use, it regulates the water supply, allowing for precise adjustments in flow rate and temperature. This isolation valve effectively manages water distribution, ensuring optimal performance and efficiency in cooling tower operations.

Features of Cooling Tower Isolation Valve

- Robust Construction: The Cooling Tower Isolation Valve is built with durable materials to withstand harsh operating conditions, ensuring long-term reliability.

- Precise Flow Control: Equipped with advanced control mechanisms, this valve enables precise regulation of water flow to cooling towers, optimizing performance.

- Leakage Prevention: Featuring tight sealing technology, the valve minimizes the risk of leaks, enhancing overall system efficiency and preventing water wastage.

- Corrosion Resistance: Constructed from corrosion-resistant materials, the valve is suitable for use in diverse environments, increasing its lifespan and reliability.

- Easy Maintenance: Designed for ease of maintenance, the valve’s accessible components facilitate quick servicing, minimizing downtime and operational costs.

- Versatile Applications: Suitable for various cooling tower setups, including industrial, commercial, and HVAC systems, providing flexibility in use.

- Compatibility: Compatible with different types of fluids and operating pressures, ensuring adaptability to different system requirements.

Advantages of Cooling Tower Isolation Valve

- Efficient Water Management: The Cooling Tower Isolation Valve allows precise control over water flow to cooling towers, optimizing water usage and reducing wastage.

- Enhanced System Performance: By regulating water supply, this valve ensures consistent cooling tower operation, leading to improved system efficiency and performance.

- Preventive Maintenance: The valve facilitates easier maintenance scheduling by allowing isolation of specific sections of the cooling system, reducing downtime for repairs and servicing.

- Cost Savings: Through its efficient water management and preventive maintenance capabilities, the valve helps minimize operational costs associated with cooling tower systems.

- Extended Equipment Lifespan: By maintaining optimal operating conditions and reducing strain on equipment, the valve contributes to prolonging the lifespan of cooling tower components.

- Versatility: Suitable for various cooling tower setups and compatible with different fluids, the valve offers versatility in application and usage across different industries and environments.

The Specifications of Cooling Tower Isolation Valve

| Specification | Details |

|---|---|

| Type | Ball valve |

| Ball Material | Stainless steel AISI 316 |

| Attachment Type | Flanged |

| Thread Standard | N/A |

| Thread Size | N/A |

| Body Material | Carbon steel ASTM A105 |

| Safe for Use With | Water and compatible fluids |

| Handle Type | Lever |

| Handle Material | Carbon steel |

| Maximum Working Pressure (psi) | 150 psi |

| Maximum Working Pressure (bar) | 10.3 bar |

| Operating Pressure | Up to 100 psi (6.9 bar) |

The Parameter of Cooling Tower Isolation Valve

- Type: The Cooling Tower Isolation Valve is a ball valve designed specifically for cooling tower applications.

- Ball Material: Constructed from stainless steel AISI 316, ensuring corrosion resistance and durability.

- Attachment Type: Equipped with flanged connections for secure installation and connection to piping systems.

- Thread Standard: Not applicable; the valve utilizes flanged connections instead of threaded ones.

- Thread Size: No specific thread size as flanged connections are utilized.

- Body Material: Made of carbon steel ASTM A105, providing strength and reliability.

- Safe for Use With: Suitable for water and compatible fluids commonly used in cooling tower systems.

- Handle Type: Features a lever handle for easy manual operation.

- Handle Material: Made of carbon steel, ensuring durability and ease of use.

- Maximum Working Pressure (psi): Capable of handling pressures up to 150 psi.

- Maximum Working Pressure (bar): Rated for pressures up to 10.3 bar.

- Operating Pressure: Designed to operate effectively at pressures of up to 100 psi (6.9 bar).

The Operation Theory of Cooling Tower Isolation Valve

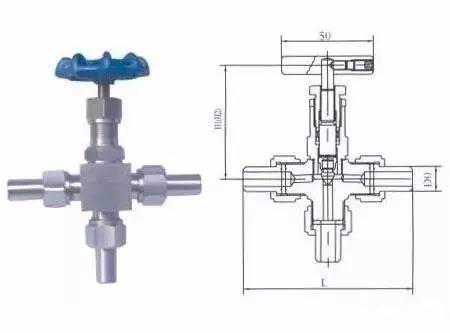

- Flanged Connections: The valve is typically installed in piping systems using flanged connections, ensuring a secure and leak-proof connection.

- Manual Operation: Equipped with a lever handle, the valve allows for easy manual operation. By turning the handle, users can open or close the valve to control the flow of water.

- Compact Size: Designed to fit standard plumbing sizes, such as the 15mm shower isolation valve, the valve is compact and space-efficient, making it suitable for various applications.

- Versatile Application: While primarily used in cooling tower systems, the Cooling Tower Isolation Valve can also be applied in other settings where precise control of water flow is required, such as showers and plumbing systems.

The Parameters Table of Cooling Tower Isolation Valve

| Parameter | Details |

|---|---|

| Type | Ball valve |

| Ball Material | Stainless steel AISI 316 |

| Stem Material | Stainless steel AISI 316 |

| Body Material | Carbon steel ASTM A105 |

| Seat Material | PTFE |

| Seat Seal Material | PTFE |

| Body Seal Material | Graphite filled PTFE |

| Handle Material | Carbon steel |

| Attachment Type | Flanged |

| Maximum Working Pressure (psi) | 150 psi |

| Maximum Working Pressure (bar) | 10.3 bar |

| Operating Pressure | Up to 100 psi (6.9 bar) |