Slab Gate Valve – Through Conduit Gate Valve

The Application of Through Conduit Gate Valve

The Through Conduit Gate Valve, like the durable Barton 247C, is vital in industries such as oil, gas, and water treatment. Rotork and Cameron are trusted for quality. These valves ensure tight seals, minimizing leaks in demanding environments. They’re crucial for efficient flow control and safety in critical operations.

What is a Slab Gate Valve?

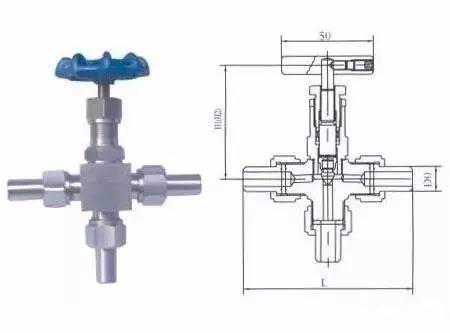

Slab gate valves are designed as full-port valves, meaning the gate’s aperture matches the pipe’s size precisely. This design ensures maximum flow capacity and minimal pressure drop, facilitating pipeline pigging when necessary.

Cameron’s slab gate valve, featuring diversion holes, maintains flow characteristics consistent with the pipeline’s diameter. Compared to conventional designs lacking diversion holes, the adjustment type offers superior flow control. Consequently, in extensive pipelines, especially within the natural gas and oil industries, the slab gate valve with diversion holes is highly preferred. ZECO Valve Group, a reputable Chinese manufacturer, produces high-quality slab gate valves meeting API 6D standards, boasting large-scale production capabilities and exceptional aesthetics.

What Is Through Conduit Gate Valve?

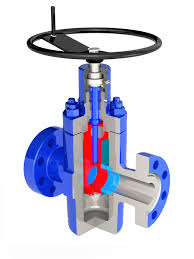

The Through Conduit Gate Valve is a robust valve designed for demanding applications where a tight seal and reliable performance are essential. It features a conduit-like passage through the valve body, allowing for unobstructed flow of fluids or gases. This design minimizes pressure drop and turbulence, making it ideal for high-pressure and high-temperature environments found in industries such as oil and gas production, refining, and pipelines. Through Conduit Gate Valves offer superior sealing capabilities, ensuring efficient flow control and preventing leakage even under extreme conditions.

Features of Through Conduit Gate Valve

- Single Gate Unit: Slab gate valves consist of a single gate that moves up and down between two seat rings.

- Suitability for Suspended Particles: The sliding gate design makes slab gate valves suitable for media with suspended particles.

- Self-Positioning Sealing Surface: The sealing surface of slab gate valves is self-positioning and remains undamaged by thermal deformation of the body.

- Minimal Overloading: Hot elongation of the stem does not overload the sealing surface even when the valve is closed in a cold state.

- Smooth Flow Path: When fully open, slab gate valves provide a smooth and linear bore with minimal flow resistance coefficient and pressure loss.

- Grease Injection Hole: ZECO slab gate valves feature a grease injection hole for easy maintenance and sealant injection to ensure normal valve performance.

- Low Flow Resistance: When fully open, the channel forms a straight pipeline with minimal flow resistance coefficient and pressure loss, reducing pipeline operation costs.

- Automatic Pressure Relief: Equipped with an automatic pressure relief device to protect against overpressure in the valve body’s middle chamber.

- Floating Seat Structure: The floating seat structure ensures sealing in both directions for enhanced reliability.

The Specifications of Through Conduit Gate Valve

| Specification | Details |

|---|---|

| Type | Through Conduit Gate Valve |

| Ball Material | N/A |

| Attachment Type | Flanged or Welded |

| Thread Standard | N/A |

| Thread Size | N/A |

| Body Material | Carbon Steel or Stainless Steel |

| Safe for Use With | Various fluids and gases |

| Handle Type | Manual or Actuated |

| Handle Material | Carbon Steel or Stainless Steel |

| Maximum Working Pressure psi | Depends on size and class |

| Maximum Working Pressure bar | Depends on size and class |

| Operating Pressure | Varies depending on application |

The Parameter of Through Conduit Gate Valve

- Type: Through Conduit Gate Valve

- Body Material: Carbon Steel or Stainless Steel

- Seat Material: Metal or Soft Seated

- Operation: Manual, Gear Operated, or Actuated

- Size Range: Typically from 2 inches to 48 inches

- Pressure Rating: ANSI Class 150 to 2500 or PN 10 to PN 420

- Temperature Range: Up to 650°C (1200°F) depending on materials and configuration

- End Connections: Flanged, Welded, or Threaded

- Design Standard: API 6D or API 6DSS for offshore applications

- Sealing Mechanism: Bidirectional sealing, providing tight shut-off in both directions

- Application: Used in pipelines for oil, gas, and petrochemical industries, as well as in power plants and water treatment facilities.

The Operation Theory of Through Conduit Gate Valve

The operation theory of Through Conduit Gate Valve involves the movement of a gate between two seat rings to control fluid flow. This gate, typically a slab or parallel gate, is mounted on a stem actuated by a handwheel, gear operator, or actuator. When open, the gate lifts to allow fluid passage; when closed, it lowers to block flow. The balancing valve symbol indicates a valve regulating fluid flow in piping systems. Balancing valves, such as Barton 200AS and ITT Barton 288C, maintain proper flow distribution. They’re adjusted to control flow rates in different branches, ensuring balanced operation.

The Parameters Table of Through Conduit Gate Valve

| Parameter | Description |

|---|---|

| Type | Through Conduit Gate Valve |

| Size | Various sizes available |

| Body Material | Carbon steel, stainless steel, alloy steel, etc. |

| Gate Material | Carbon steel, stainless steel, alloy steel, etc. |

| Seat Material | Metal, graphite, polymeric, etc. |

| Stem Material | Stainless steel, carbon steel, etc. |

| Seat Type | Floating or slab |

| Operation | Manual, gear operated, electric, pneumatic, etc. |

| Pressure Rating | ANSI Class 150 – 2500, PN 10 – PN 420 |

| End Connection | Flanged, butt-welded, threaded |

| Temperature Range | Varies based on material and design |

| Service | Various, including oil, gas, water, etc. |