Manual Butterfly Valve

the application of Manual Butterfly Valve

The Manual Butterfly Valve, manufactured by Cameron and also known as the DeZURIK Butterfly Valve, is a reliable choice for fluid control applications. Unlike lug vs wafer butterfly valves, the manual butterfly valve offers versatility with its various configurations, including lug and wafer styles. With a size range that includes 8 butterfly valve, it caters to diverse pipeline requirements in industries such as oil and gas, water treatment, and chemical processing. Known for its robust construction and dependable performance, the manual butterfly valve ensures efficient flow control and is suitable for both low-pressure and high-pressure applications. Its ease of operation and maintenance make it a preferred choice in critical industrial operations.

The Parameter of Manual Butterfly Valve

- Valve Type: Manual Butterfly Valve

- Brand: Manufactured by Cameron, a renowned industry name.

- Configuration: Available in lug and wafer styles.

- Size Range: Includes 8 butterfly valve and various other sizes.

- Pressure Rating: Suitable for both low and high-pressure applications.

- Material: Constructed from high-quality materials for durability.

- End Connection: Equipped with lug or wafer end connections.

- Sealing Mechanism: Utilizes advanced sealing technology.

- Application: Ideal for industries requiring reliable fluid control.

- Versatility: Offers efficiency in diverse industrial settings.

The Operation Theory of Manual Butterfly Valve

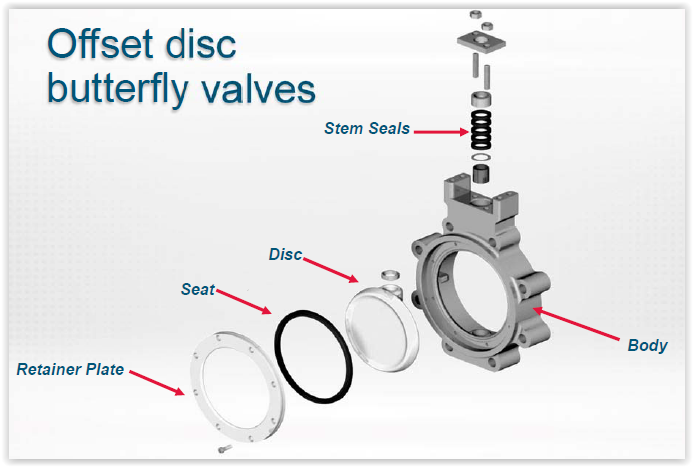

The operation theory of the Manual Butterfly Valve is similar to other butterfly valves such as ABZ Butterfly Valves and flanged butterfly valve. It involves the rotation of a disc mounted on a shaft to control the flow of fluid. When the valve is open, the disc rotates parallel to the flow direction, allowing fluid passage. Conversely, when closed, it rotates perpendicular to the flow direction, blocking fluid flow. This simple yet effective mechanism provides reliable flow control in various industrial applications.

The Parameters Table of Manual Butterfly Valve

| Parameter | Description |

|---|---|

| Valve Type | Manual Butterfly Valve |

| Brand | Cameron |

| Configuration | Lug and Wafer |

| Size Range | 8″ and various other sizes |

| Pressure Rating | Suitable for low and high-pressure applications |

| Material | High-quality materials for durability |

| End Connection | Lug or Wafer flanged |

| Sealing Mechanism | Advanced sealing technology |

| Application | Suitable for industries requiring fluid control |

| Versatility | Efficient in diverse industrial settings |

Relevant Information about Manual Butterfly Valve

- Rotor (Rator): In a butterfly valve, the disc or “rotor” rotates to control the flow of fluid through the valve.

- Stator: Butterfly valves typically do not have a stator component. The body of the valve provides stability and support for the rotor.

- Universal Joint: Universal joints are not typically found in butterfly valves. They are more commonly used in mechanical systems to transmit torque between non-aligned shafts.

- Shaft Seal: Butterfly valves may have shaft seals to prevent leakage along the valve stem. These seals can be made of materials like elastomers or PTFE.

- Driving System: In manual butterfly valves, the driving system involves a handle or lever that the operator uses to manually open or close the valve. In automated butterfly valves, a driving system such as an electric, pneumatic, or hydraulic actuator is used to control the valve remotely.