Venturi Valve

The Application of Venturi Valve

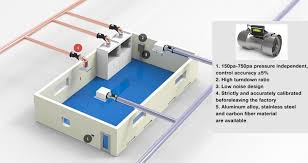

Introducing the Rotork Venturi Valve, a pivotal component in industrial fluid systems. Engineered for precision and durability, it offers versatile applications akin to a 3/4 pressure relief valve, ball valve for pressure washer, and high-pressure valve. Rotork’s expertise ensures optimal performance in regulating fluid flow and pressure, making it indispensable in various industrial processes. The Venturi Valve’s innovative design facilitates efficient fluid movement, enhancing system efficiency and reliability. Trust Rotork for cutting-edge solutions, with the Venturi Valve leading the way in fluid control technology.

What Is Venturi Valve?

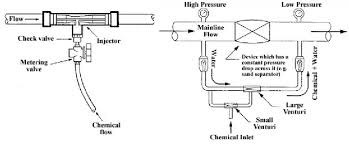

A Venturi Valve is a device used to regulate fluid flow by creating a constriction in the flow path, which increases the fluid velocity and decreases pressure, allowing for precise control of flow rates.

How Does Venturi Valve work?

The Venturi Valve works by utilizing the Venturi effect, where a narrowing in the flow path accelerates fluid velocity, reducing pressure. This pressure difference allows for precise control of flow rates and is commonly used in various fluid systems for efficient regulation.

Features of Venturi Valve

- Efficient Design: Venturi Valves feature a streamlined design that optimizes fluid flow and minimizes pressure drop.

- Precise Flow Control: They allow for precise regulation of flow rates by utilizing the Venturi effect.

- Versatility: Venturi Valves are versatile and suitable for various applications in fluid systems.

- Low Maintenance: Due to their simple design and few moving parts, Venturi Valves require minimal maintenance.

- Reliable Operation: These valves offer reliable performance, ensuring consistent flow control over time.

- Wide Range of Applications: They are used in diverse industries, including water treatment, HVAC systems, and industrial processes.

- Cost-Effective: Venturi Valves provide efficient flow control at a relatively low cost compared to other flow control devices.

- Reduced Energy Consumption: By optimizing flow rates and minimizing pressure drop, Venturi Valves help reduce energy consumption in fluid systems.

- Longevity: Constructed from durable materials, Venturi Valves exhibit longevity and resilience in demanding operating conditions.

Advantages of Venturi Valve

Advantages of Venturi Valve include precise flow control, efficient design, versatility, low maintenance, reliable operation, wide range of applications, cost-effectiveness, reduced energy consumption, and longevity.

The Specifications of Venturi Valve

| Specification | Details |

|---|---|

| Type | Venturi Valve |

| Ball Material | N/A |

| Attachment Type | Threaded |

| Thread Standard | ANSI/ASME B1.20.1 |

| Thread Size | Various sizes available |

| Body Material | Stainless Steel |

| Safe for Use With | Various fluids and gases |

| Handle Type | Lever |

| Handle Material | Stainless Steel |

| Maximum Working Pressure | 150 psi |

| Maximum Working Pressure | 10.34 bar |

| Operating Pressure | Dependent on system settings |

The Parameter of Venturi Valve

- Type: Venturi Valve

- Ball Material: N/A

- Attachment Type: Threaded

- Thread Standard: ANSI/ASME B1.20.1

- Thread Size: Various sizes available

- Body Material: Stainless Steel

- Safe for Use With: Various fluids and gases

- Handle Type: Lever

- Handle Material: Stainless Steel

- Maximum Working Pressure: 150 psi (10.34 bar)

- Operating Pressure: Dependent on system settings

The Operation Theory of Venturi Valve

The operation theory of a Venturi Valve involves utilizing the Venturi effect to control fluid flow. Similar to a pressure washer valve or tyre pressure valve caps, it creates a constriction in the flow path, accelerating fluid velocity and reducing pressure. This pressure difference enables precise regulation of flow rates in various fluid systems.

The Parameters Table of Venturi Valve

| Parameter | Details |

|---|---|

| Type | Venturi Valve |

| Ball Material | N/A |

| Attachment Type | Threaded |

| Thread Standard | ANSI/ASME B1.20.1 |

| Thread Size | Various sizes available |

| Body Material | Stainless Steel |

| Seal Material | Rubber or Silicone |

| Safe for Use With | Various fluids and gases |

| Handle Type | Lever |

| Handle Material | Stainless Steel |

| Maximum Working Pressure | 150 psi |

| Maximum Working Pressure | 10.34 bar |

| Operating Pressure | Dependent on system settings |