Venturi Valves

The Application of Venturi Valves

Venturi valves, including venturi valve, are essential components in various systems for controlling fluid or gas flow. Venturi air valve variants, such as those from Phoenix Venturi Valve, play a crucial role in regulating airflow in HVAC systems, industrial processes, and pneumatic systems. These valves operate on the principle of fluid dynamics, utilizing a constricted section to create a pressure drop, allowing for precise control of flow rates. With a maximum operating pressure of 3 bar, Venturi valves find applications in diverse industries where accurate flow control is paramount, ensuring efficient and optimized system performance.

phoenix controls venturi valve

venturi air valve

phoenix air valves

phoenix venturi valve

venturi valve hvac

phoenix control valve

venturi valve

venturi check valve

venturi air valves

phoenix air valve

phoenix controls venturi air valves

venturi air valve price

price venturi valves

What Is Venturi Valves?

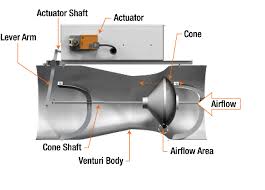

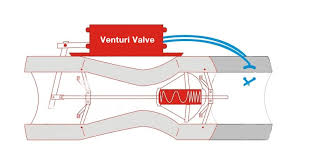

Venturi valves are specialized flow control devices designed to regulate fluid or gas flow by utilizing the Venturi effect. In essence, they feature a constricted section that creates a pressure drop, allowing for precise control of flow rates. These valves are widely used in various industries and applications, including HVAC systems, industrial processes, and pneumatic systems, to ensure efficient and optimized flow control.

How Does Venturi Valves work?

Venturi valves operate based on the Venturi effect, which involves fluid passing through a constricted section. As fluid flows through the narrowed portion of the valve, its velocity increases while its pressure decreases. This pressure drop allows for precise control of flow rates, making Venturi valves effective in regulating fluid or gas flow in various systems.

Features of Venturi Valves

- Efficiency: Venturi valves offer high efficiency in fluid flow regulation due to their design, which minimizes energy loss during operation.

- Versatility: They can be used in a wide range of applications, including water treatment, HVAC systems, and industrial processes.

- Accurate Flow Control: Venturi valves provide precise control over flow rates, making them suitable for applications where precise fluid or gas regulation is necessary.

- Low Maintenance: With fewer moving parts compared to other types of valves, Venturi valves require minimal maintenance, reducing downtime and operational costs.

- Compact Design: Their compact design allows for easy installation in tight spaces, making them suitable for various installation environments.

- Durability: Constructed from high-quality materials, Venturi valves exhibit excellent durability and resistance to corrosion, ensuring long-term reliability in demanding conditions.

Advantages of Venturi Valves

- Efficient Flow Regulation: Venturi valves offer efficient flow regulation by utilizing the Venturi effect to control fluid or gas flow rates effectively.

- Precise Control: They provide precise control over flow rates, allowing for accurate adjustment and modulation of fluid or gas flow.

- Energy Efficiency: Due to their design, Venturi valves minimize energy loss during operation, resulting in energy-efficient performance.

- Low Maintenance Requirements: With fewer moving parts and a simple design, Venturi valves require minimal maintenance, reducing downtime and operational costs.

- Versatility: Venturi valves can be used in various applications across different industries, thanks to their versatile design and adaptable functionality.

- Reliability: Constructed from durable materials and engineered for robust performance, Venturi valves offer high reliability and long-term service life in demanding operating conditions.

The Specifications of Venturi Valves

Sure, here’s a table outlining the specifications of Venturi Valves:

| Specification | Description |

|---|---|

| Type | Venturi Valve |

| Ball Material | N/A |

| Attachment Type | N/A |

| Thread Standard | N/A |

| Thread Size | N/A |

| Body Material | Stainless steel, brass, or other suitable material |

| Safe for Use With | Various fluids and gases |

| Handle Type | N/A |

| Handle Material | N/A |

| Maximum Working Pressure | Depends on design and material, typically ranges from 3 bar to 10 bar |

| Maximum Working Pressure | Depends on design and material, typically ranges from 30 psi to 150 psi |

| Operating Pressure | Typically 3 bar |

The Parameter of Venturi Valves

- Type: Venturi Valves are specialized flow control devices used to accurately measure fluid flow rates in pipelines.

- Material: Venturi Valves are typically constructed from durable materials such as stainless steel, brass, or other corrosion-resistant alloys.

- Functionality: They work on the principle of Bernoulli’s equation, which states that an increase in the velocity of a fluid occurs simultaneously with a decrease in pressure or a decrease in the fluid’s potential energy. Venturi Valves utilize this principle to create a pressure difference between the inlet and throat sections, enabling accurate flow rate measurement.

- Application: Venturi Valves are commonly employed in various industries, including oil and gas, water treatment, chemical processing, and HVAC systems, to measure and control fluid flow rates accurately.

- Design Variants: There are different designs of Venturi Valves available, including standard Venturi tubes, Venturi flow meters, and Venturi scrubbers, each tailored to specific applications and flow rate measurement requirements.

- Installation: Venturi Valves are installed inline within pipelines, with the flow directed through the constricted section (throat) of the device. Proper installation and calibration are crucial for accurate flow measurement.

- Maintenance: Regular maintenance and calibration are essential to ensure the continued accuracy and reliability of Venturi Valves. This may involve cleaning, inspection, and recalibration as needed.

- Operating Conditions: Venturi Valves operate effectively within specified temperature and pressure ranges, typically up to 3 bar of pressure and within ambient temperature conditions.

- Accuracy: When properly calibrated and maintained, Venturi Valves offer high accuracy in measuring fluid flow rates, making them suitable for various industrial applications.

The Operation Theory of Venturi Valves

- Phoenix Controls Venturi Valve: Phoenix Controls Venturi Valves are precision-engineered to provide accurate flow control and measurement in critical airflow applications, such as cleanrooms, laboratories, and healthcare facilities. They utilize the Venturi effect to achieve precise airflow regulation while maintaining energy efficiency and system stability.

- Venturi Air Valves: In pneumatic systems, Venturi Air Valves utilize the Venturi effect to create a pressure differential, which allows for the regulation of air flow rates. These valves are commonly used in compressed air systems, HVAC systems, and industrial processes to control air flow and pressure.

- Venturi Valve for Water: Similarly, Venturi Valves designed for water applications utilize the same principle to accurately measure and control water flow rates in pipelines. These valves are commonly used in water treatment plants, irrigation systems, and plumbing systems to ensure efficient water distribution and flow control.

The Parameters Table of Venturi Valves

| Parameter | Description |

|---|---|

| Type | Venturi Valve |

| Material | Stainless Steel, Brass, PVC, or other suitable materials |

| Attachment Type | Flanged, Threaded, Socket Weld, or Butt Weld |

| Thread Standard | ANSI, DIN, JIS, BS, or others |

| Thread Size | Various sizes depending on application and standard |

| Body Material | Stainless Steel, Brass, PVC, or other suitable materials |

| Safe for Use With | Air, Water, Gas, Steam, or other compatible fluids |

| Maximum Working Pressure (psi) | Typically ranges from 150 psi to 6000 psi |

| Maximum Working Pressure (bar) | Typically ranges from 10 bar to 420 bar |

| Operating Pressure | As per system requirements |