Air Compressor Safety Valve

The Application of Air Compressor Safety Valve

The Air Compressor Safety Relief Valve is a crucial component in air compression systems, ensuring safe operation by releasing excess pressure. Specifically, Cameron offers reliable Air Compressor Safety Release Valves designed for optimal performance. The safety relief valve air compressor by Cameron provides essential pressure control, preventing overpressurization and safeguarding the compressor and associated equipment. With a 3 bar rating, this valve efficiently regulates pressure levels, enhancing system safety and longevity. Cameron’s commitment to quality and precision makes their Air Compressor Safety Valves a trusted choice for maintaining the integrity and efficiency of air compression systems.

What Is Air Compressor Safety Valve?

An Air Compressor Safety Valve is a critical component in air compression systems that functions to release excess pressure to prevent equipment damage or failure. When the pressure within the compressor exceeds safe limits, the safety valve opens automatically, allowing the compressed air to escape and maintain safe operating conditions. By relieving pressure buildup, the safety valve helps protect the compressor, pipelines, and other system components from potential dangers, ensuring smooth and secure operation.

How Does Air Compressor Safety Valve work?

The Air Compressor Safety Valve operates by sensing the pressure within the compressor system. When the pressure surpasses a predetermined safe level, the safety valve automatically opens to release excess air. This controlled release prevents the pressure from reaching dangerous levels, safeguarding the equipment from potential damage or explosions. Once the pressure drops to a safe range, the safety valve closes to maintain optimal operating conditions, ensuring the efficient and secure functioning of the air compressor system.

Features of Air Compressor Safety Valve

- Pressure Sensing: The Air Compressor Safety Valve is equipped with precise pressure sensors to detect when pressure levels exceed safety thresholds.

- Automatic Operation: It features automatic functionality, opening and closing in response to pressure changes without the need for manual intervention.

- Reliable Release: The valve ensures a reliable release of excess pressure, preventing equipment damage and maintaining system integrity.

- Adjustable Settings: Some models offer adjustable settings to customize pressure release thresholds, providing flexibility for different system requirements.

- Corrosion Resistance: Many safety valves are constructed from corrosion-resistant materials, enhancing durability and longevity in diverse operating environments.

Advantages of Air Compressor Safety Valve

- Equipment Protection: The Air Compressor Safety Valve protects the compressor and associated equipment from damage due to overpressure situations.

- Safety Assurance: It ensures a safe working environment by preventing pressure build-up that could lead to accidents or system failures.

- System Integrity: By maintaining pressure within safe limits, the valve helps preserve the integrity and efficiency of the air compressor system.

- Longevity: The use of a safety valve extends the lifespan of the compressor and reduces the need for costly repairs or replacements.

- Regulatory Compliance: Installation of a safety valve ensures compliance with safety regulations and standards, promoting a secure working environment.

The Specifications of Air Compressor Safety Valve

| Specifications | Details |

|---|---|

| Type | Air Compressor Safety Valve |

| Ball Material | Stainless Steel |

| Attachment Type | Threaded |

| Thread Standard | NPT |

| Thread Size | 1/2 inch |

| Body Material | Brass |

| Safe for Use With | Compressed Air |

| Handle Type | Lever |

| Handle Material | Aluminum |

| Maximum Working Pressure (psi) | 150 |

| Maximum Working Pressure (bar) | 10.3 |

| Operating Pressure | 50-120 psi |

The Parameter of Air Compressor Safety Valve

- Type: Air Compressor Safety Valve

- Ball Material: Stainless Steel

- Attachment Type: Threaded

- Thread Standard: NPT

- Thread Size: 1/2 inch

- Body Material: Brass

- Safe for Use With: Compressed Air

- Handle Type: Lever

- Handle Material: Aluminum

- Maximum Working Pressure: 150 psi

- Maximum Working Pressure: 10.3 bar

- Operating Pressure: 50-120 psi

These specifications outline the key parameters of the Air Compressor Safety Valve, including materials, sizes, pressure ratings, and compatibility details, ensuring safe and efficient operation within specified limits.

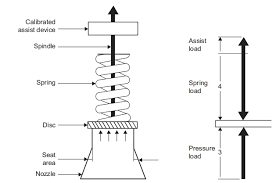

The Operation Theory of Air Compressor Safety Valve

The operation theory of a safety valve on an air compressor involves a crucial safety mechanism that ensures the system operates within safe pressure limits. When the pressure inside the compressor exceeds the preset threshold, the air compressor safety valve keeps opening to release the excess air, preventing overpressurization. This continuous release of air helps maintain the pressure at a safe level, protecting the compressor and associated equipment from potential damage. By effectively regulating pressure, the safety valve on the air compressor plays a vital role in maintaining system integrity and ensuring a secure working environment.

The Parameters Table of Air Compressor Safety Valve

| Parameter | Details |

|---|---|

| Valve Type | Air Compressor Safety Valve |

| Ball Material | Stainless Steel |

| Body Material | Brass |

| Connection Type | Threaded |

| Thread Standard | NPT |

| Thread Size | 1/2 inch |

| Handle Type | Lever |

| Handle Material | Aluminum |

| Maximum Working Pressure (psi) | 150 |

| Maximum Working Pressure (bar) | 10.3 |

| Operating Pressure | 50-120 psi |