ASME VIII Safety Relief Valve – 5211 Series

The Application of Safety Relief Valve

Cameron, a leading brand in industrial solutions, specializes in providing reliable safety relief valves for various applications, including boiler safety relief valve leaking, air compressor safety relief valve, and steam safety relief valve. These valves serve as critical safety devices, designed to prevent overpressure situations in equipment and systems. In the event of excess pressure, the safety relief valve automatically opens, releasing the pressure and safeguarding against potential damage or catastrophic failure. Cameron’s safety relief valves are engineered for durability, precision, and adherence to strict industry standards, ensuring optimal performance and protection in diverse industrial environments.

What Are The Types Of Safety Relief Valve?

- Spring-Loaded Safety Relief Valves: These valves utilize a spring mechanism to maintain a set pressure level. When the system pressure exceeds the set limit, the spring compresses, allowing the valve to open and release excess pressure.

- Pilot-Operated Safety Relief Valves: Pilot-operated valves use a smaller control valve (pilot) to sense system pressure. When the pressure exceeds the set limit, the pilot valve opens, causing the main valve to open and relieve pressure.

- Rupture Disc Safety Relief Valves: Also known as bursting disc valves, these devices consist of a thin metal disc designed to rupture at a predetermined pressure. When the system pressure exceeds the disc’s burst pressure, it ruptures, allowing pressure relief.

- Conventional Safety Relief Valves: These valves operate based on the direct force of the system pressure. When the pressure exceeds the set limit, the valve’s disc lifts off its seat, allowing excess pressure to escape.

- Balanced Safety Relief Valves: Balanced valves use additional components, such as bellows or pistons, to balance the pressure across the valve. This design helps maintain consistent valve opening characteristics regardless of inlet pressure variations.

- High-Lift Safety Relief Valves: High-lift valves feature an extended valve lift, allowing them to discharge larger volumes of fluid at lower pressure differentials. They are commonly used in applications with low backpressure.

What Is Safety Relief Valve?

A safety relief valve is a critical component in industrial systems designed to protect equipment and personnel from overpressure situations. It automatically opens to release excess pressure in a system, preventing potential damage or catastrophic failure. Safety relief valves are essential for maintaining the integrity and safety of various processes, including boilers, air compressors, and steam systems, by ensuring pressure remains within safe operating limits.

How to Select the Right Safety Relief Valve?

When selecting the right safety relief valve, consider factors such as system pressure ratings, flow capacity, and compatibility with the fluid being handled. Ensure the valve is certified and compliant with industry standards for safety and performance. Additionally, assess the operating conditions, including temperature and environment, to choose a valve with suitable materials and construction for long-term reliability. Conduct thorough evaluations of application-specific requirements to ensure the selected valve meets the needs of the system and provides effective overpressure protection.

Features of Safety Relief Valve

- Pressure Relief:

- Primary Function: Safety relief valves are designed to relieve excess pressure in systems to prevent damage or failure.

- Automatic Operation: They operate automatically when the pressure exceeds a predetermined limit, ensuring rapid response to overpressure situations.

- Reliable Performance:

- Robust Construction: Safety relief valves are built with durable materials such as stainless steel or brass to withstand high pressures and harsh environments.

- Consistent Operation: They offer consistent and reliable performance, ensuring effective pressure relief in various applications.

- Versatility:

- Wide Application: Safety relief valves are suitable for a wide range of industries and applications, including boilers, pressure vessels, and pipelines.

- Compatibility: They come in various sizes and configurations to accommodate different system requirements and fluid types.

- Safety Standards:

- Compliance: Safety relief valves comply with industry standards and regulations for safety and performance.

- Certifications: They may be certified by organizations such as ASME, API, or ISO to ensure quality and reliability.

- Adjustability:

- Set Pressure: Many safety relief valves allow for adjustable set pressures to meet specific system requirements.

- Precision: They offer precise pressure control, ensuring accurate relief at the desired pressure level.

- Leakage Prevention:

- Sealing Mechanism: Safety relief valves incorporate effective sealing mechanisms to prevent leakage when not in operation.

- Tight Shut-off: They provide tight shut-off when the pressure returns to normal levels, minimizing fluid loss and system downtime.

Advantages and Disadvantages of Safety Relief Valve

Advantages:

- Overpressure Protection:

- Safety relief valves provide essential protection against overpressure situations, preventing damage to equipment and ensuring personnel safety.

- Automatic Operation:

- They operate automatically, requiring no human intervention to relieve excess pressure, thus offering swift response in critical situations.

- Reliable Performance:

- Safety relief valves offer consistent and reliable performance, ensuring effective pressure relief under various operating conditions.

- Versatility:

- They are suitable for a wide range of applications across different industries, providing flexibility and adaptability to diverse system requirements.

- Compliance:

- Safety relief valves comply with industry standards and regulations, ensuring they meet quality and safety requirements.

Disadvantages:

- Limited Precision:

- Some safety relief valves may have limitations in precision, leading to slight fluctuations in the set pressure or relief capacity.

- Maintenance Requirements:

- Regular maintenance is necessary to ensure the proper functioning of safety relief valves, which can increase operational costs and downtime.

- Potential for Leakage:

- In certain conditions, safety relief valves may experience minor leakage, which can result in fluid loss and reduced system efficiency.

- Cost:

- High-quality safety relief valves can be costly to purchase and install, especially for larger systems or applications requiring multiple valves.

- Complexity:

- Understanding the operation and maintenance requirements of safety relief valves may require specialized knowledge and training, adding complexity to system management.

The Specifications of Safety Relief Valve

| Specification | Details |

|---|---|

| Type | Safety Relief Valve |

| Ball Material | Stainless Steel |

| Attachment Type | Screwed |

| Thread Standard | ANSI B1.20.1 |

| Thread Size | 1/2 inch – 2 inch |

| Body Material | Brass |

| Safe for Use With | Water, Steam, Air |

| Handle Type | Lever |

| Handle Material | Steel |

| Maximum Working Pressure (psi) | 600 |

| Maximum Working Pressure (bar) | 41.37 |

| Operating Pressure | 10 – 300 psi |

The Installation Steps for Safety Relief Valve

- Preparation:

- Gather necessary tools such as wrenches, pipe tape, and pipe cutter.

- Ensure the work area is clear and accessible.

- Shut Off System:

- Close the main supply valve to prevent fluid flow during installation.

- Select Valve Location:

- Choose an appropriate location for the safety relief valve, considering accessibility and system requirements.

- Prepare Pipe Ends:

- Clean and deburr pipe ends to ensure smooth surface for proper sealing.

- Apply Thread Sealant:

- Apply thread sealant or pipe tape to the male threads of the valve to create a secure seal.

- Attach Valve:

- Screw the safety relief valve onto the pipe, ensuring it is securely tightened using appropriate wrenches.

- Connect Pipes:

- Connect remaining pipes to the inlet and outlet ports of the valve, ensuring proper alignment and tightening to prevent leaks.

- Test for Leaks:

- Turn on the main supply valve and test the valve for leaks by visually inspecting all connections and listening for unusual sounds.

- Adjust Set Pressure:

- Adjust the set pressure of the safety relief valve according to system requirements, if necessary.

- Operational Test:

- Open and close the valve to verify smooth operation and ensure proper functionality.

- Secure Valve:

- Once satisfied with installation, secure the valve in place using mounting brackets or straps to prevent movement.

- Label Valve:

- Label the safety relief valve with appropriate signage indicating its purpose and set pressure for easy identification.

The Operation Theory of Safety Relief Valve

Certainly! Here’s an overview of the operation theory of safety relief valves, focusing on specific examples like the Apollo Safety Relief Valve and a 150 psi safety relief valve:

Operation Theory of Safety Relief Valve:

Safety relief valves are essential components in industrial systems designed to protect equipment and personnel from overpressure situations. They operate based on simple yet effective principles to ensure rapid response and reliable performance during emergencies.

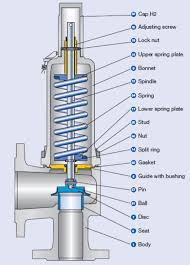

Key Components:

- Spring Mechanism: Safety relief valves typically incorporate a spring mechanism that applies force to keep the valve closed under normal operating conditions.

- Pressure Sensing: These valves are equipped with a mechanism to sense the pressure within the system.

- Valve Disc: When the system pressure exceeds the set limit, the force exerted by the pressure overcomes the spring tension, causing the valve disc to lift off its seat.

- Pressure Relief: As the valve opens, excess pressure is relieved from the system, preventing damage or catastrophic failure.

- Reset Mechanism: Once the pressure returns to normal levels, the spring re-seats the valve disc, closing the valve until the next overpressure event occurs.

Specific Examples:

- Apollo Safety Relief Valve: Apollo safety relief valves are renowned for their reliability and performance in various industrial applications. They operate on the same principles as other safety relief valves, providing effective overpressure protection.

- 150 psi Safety Relief Valve: A 150 psi safety relief valve is specifically designed to relieve pressure when it exceeds 150 pounds per square inch (psi). These valves are calibrated to open at a predetermined pressure threshold, ensuring precise and accurate pressure relief.

Conclusion:

Safety relief valves, including models such as the Apollo Safety Relief Valve and the 150 psi safety relief valve, play a critical role in maintaining the safety and integrity of industrial systems. By effectively relieving excess pressure, these valves help prevent damage to equipment and ensure the safety of personnel in emergency situations.