Trim of Valves

The Application of Trim of Valves

The Application of Trim of Valves is crucial for maintaining the performance and reliability of industrial valves. Valve Trim Maintenance Services provided by leading manufacturers like Cameron ensure the optimal functioning of valve components over their lifetime. Valve Trim Components, such as gates, seats, and stems, are regularly inspected and reconditioned using specialized Valve Trim Reconditioning Processes. This comprehensive approach helps to extend the service life of valves, reduce maintenance costs, and minimize unplanned downtime. By investing in professional Valve Trim solutions, industrial facilities can maximize the efficiency and safety of their critical valve infrastructure.

cameron valves

balancing valve symbol

What Are The Types Of Trim of Valves?

Standard Trim:

This is the basic trim configuration that comes standard with the valve. It is designed to handle typical operating conditions and media.

Specialized Trim:

Specialized trim is engineered to address specific application requirements, such as increased flow capacity, noise reduction, or enhanced throttling performance.

Severe Service Trim:

Valves operating in harsh, abrasive, or corrosive environments often require severe service trim. This includes materials like Stellite 6, tungsten carbide, or ceramics to withstand the extreme conditions.

Cryogenic Trim:

For valves handling cryogenic fluids like liquid natural gas or liquid oxygen, cryogenic-rated trim materials are used to maintain performance at low temperatures.

Anti-Cavitation Trim:

In applications with high-pressure drop, anti-cavitation trim features specialized designs to prevent damaging cavitation and flashing.

Antistatic Trim:

Antistatic trim is used in valves for hazardous or flammable services to dissipate static electricity and mitigate the risk of ignition.

What Is the Trim of a Valve?

The trim of a valve refers to the internal components that control the flow of fluid through the valve. This includes the valve seat, valve plug or ball, stem, and other dynamic parts that come into contact with the process media. The trim is responsible for regulating the opening and closing of the valve, as well as modulating the flow rate. The design and materials of the trim are critical to the valve’s performance, as they must withstand the wear, corrosion, and other stresses imposed by the operating conditions. Selecting the proper trim configuration is essential to ensure the reliable, efficient, and safe operation of industrial valves across a wide range of applications, from oil and gas processing to power generation and chemical manufacturing.

How to Select the Right Trim of Valves?

Selecting the right valve trim requires a careful consideration of the operating parameters and service conditions. Key factors to evaluate include pressure, temperature, flow rate, media properties (corrosiveness, abrasiveness, viscosity, etc.), and potential for cavitation or flashing. Engineers must also assess the valve’s desired performance characteristics, such as flow capacity, rangeability, and noise/vibration requirements. Based on these criteria, appropriate trim materials (e.g., Stellite, tungsten carbide, ceramics) and trim designs (e.g., anti-cavitation, antistatic) can be specified to ensure the valve meets the application’s demands. Working closely with valve manufacturers or trim specialists helps ensure the optimal trim selection for reliable, efficient, and safe valve operation.

Features of Trim of Valves

Durability:

The trim components must be highly durable to withstand the wear, corrosion, and other stresses imposed by the operating environment. Specialized materials like Stellite, tungsten carbide, and ceramics are often used to enhance the trim’s lifespan.

Flow Optimization:

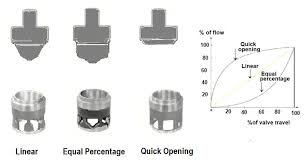

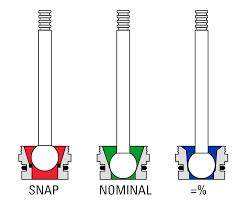

The trim design plays a crucial role in optimizing the valve’s flow characteristics, such as flow capacity, rangeability, and noise/vibration reduction. Advanced trim configurations can improve overall system efficiency.

Pressure Regulation:

In applications with high-pressure drop, the trim design must be able to regulate the pressure to prevent damaging cavitation and flashing effects.

Media Compatibility:

The trim materials must be carefully selected to ensure compatibility with the process media, whether it is corrosive, abrasive, or cryogenic in nature.

Safety and Reliability:

Proper trim selection and maintenance are essential for maintaining the safety and reliability of industrial valves, particularly in hazardous or mission-critical applications.

Advantages and Disadvantages of Trim of Valves

Advantages of Valve Trim:

Enhanced Performance: Specialized trim designs can improve the valve’s flow capacity, rangeability, and noise/vibration characteristics, leading to more efficient system operation.

Improved Reliability: Durable trim materials and proper maintenance can extend the valve’s service life and reduce the risk of unplanned downtime.

Customized Solutions: Trim can be tailored to specific application requirements, such as handling harsh media or operating in extreme conditions.

Cost Savings: Investing in high-quality trim can help minimize maintenance costs and increase the overall lifespan of the valve.

Disadvantages of Valve Trim:

Complexity: The selection and installation of specialized trim can be more complex than standard configurations, requiring additional engineering expertise.

Higher Initial Costs: Customized trim solutions may have higher upfront costs compared to basic valve designs.

Maintenance Requirements: Proper maintenance and periodic inspection of the trim are necessary to ensure continued performance and reliability.

Limited Interchangeability: Specialized trim may not be compatible with different valve models or brands, reducing flexibility in valve replacements.

The Specifications of Trim of Valves

| Specification | Details |

|---|---|

| Type | Ball Valve |

| Ball Material | 316 Stainless Steel |

| Attachment Type | Threaded |

| Thread Standard | NPT |

| Thread Size | 1/2 inch |

| Body Material | 316 Stainless Steel |

| Safe for Use With | Oxygen, Natural Gas, Propane, Water, Oil, Air |

| Handle Type | Lever |

| Handle Material | 316 Stainless Steel |

| Maximum Working Pressure | 1000 psi |

| Maximum Working Pressure | 69 bar |

| Operating Pressure | 0-1000 psi |

The Operation Theory of Trim of Valves

The operation theory of Valve Trim is centered around regulating the flow of fluid through the valve. The trim components, which include the valve seat, plug or ball, and stem, work in conjunction to control the opening and closing of the valve, as well as modulate the flow rate.

High-Wear Valve Trim Refurbishment:

In applications with highly abrasive, corrosive, or erosive media, the valve trim can experience significant wear over time. Refurbishment services from specialized providers can restore these high-wear trim components to like-new condition. This involves carefully inspecting the parts, replacing worn elements, and re-machining or rebuilding the trim to exacting specifications. Refurbishment helps extend the service life of the valve and avoid costly unplanned downtime.

Customized Valve Trim Solutions:

To address the unique requirements of different applications, valve manufacturers offer customized trim solutions. This allows the trim to be engineered with the appropriate materials, designs, and configurations to handle specific process conditions, such as high temperatures, high pressures, corrosive media, or the potential for cavitation. By working closely with the valve supplier, end-users can specify the optimal trim configuration to ensure reliable, efficient, and safe valve operation.