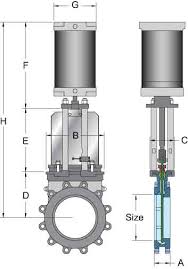

Pneumatic Gate Valve

The Application of Pneumatic Gate Valve

Pneumatic Gate Valve is a crucial component widely employed in various industries, including those served by cooling tower valve companies. Constructed with durable C12A material, it ensures reliability in demanding applications. This valve, often symbolized by the slide valve symbol, facilitates precise control and isolation of fluid flow within pipelines. With Rotork and Cameron offering their versions like the Carbon Steel Gate Valve, pneumatic gate valves find extensive use in systems requiring automated operation, thanks to their compatibility with pneumatic actuators. Their robust design and efficient operation make them ideal for applications demanding high performance and reliability.

What Is Pneumatic Gate Valve?

A Pneumatic Gate Valve is a type of valve used to control the flow of fluids within pipelines through the use of compressed air or gas. It operates by raising or lowering a gate within the valve body to either allow or block the flow of fluid. This action is typically controlled by a pneumatic actuator, which responds to signals from a control system to open or close the valve as needed. Pneumatic gate valves are commonly used in various industries, including oil and gas, water treatment, and chemical processing, due to their reliable operation and ability to quickly and efficiently regulate fluid flow.

Features of Pneumatic Gate Valve

- Sturdy Construction: The valve is built with heavy-duty cast materials, ensuring durability and reliability in demanding industrial environments.

- Standardized Bolt Hole Pattern: It features an ASA bolt hole pattern, providing compatibility and ease of installation with existing piping systems.

- Corrosion Resistance: Made from stainless steel, the valve offers excellent resistance to corrosion, extending its lifespan and maintaining performance.

- Effective Sealing: Equipped with resilient rubber seats, the valve seals effectively against both pressure and vacuum, preventing leaks and ensuring tight shut-off.

- Versatile Actuation: The valve can be operated either pneumatically or manually, offering flexibility to suit different application requirements.

- Enhanced Pneumatic Performance: Pneumatic units come with oversized air cylinders, ensuring powerful and reliable actuation for efficient fluid control.

Advantages of Pneumatic Gate Valve

- Reliable Operation: Pneumatic gate valves offer dependable performance in various industrial applications, ensuring smooth and efficient operation.

- Quick Response: They provide fast response times, allowing for rapid adjustment and control of fluid flow.

- Remote Operation: Pneumatic actuators enable remote operation, facilitating control from a centralized location and enhancing safety.

- Versatile Applications: These valves are suitable for a wide range of media, temperatures, and pressures, making them versatile for diverse industrial processes.

- Reduced Maintenance: With fewer moving parts and robust construction, pneumatic gate valves require minimal maintenance, leading to cost savings and increased uptime.

- Enhanced Safety: Pneumatic operation eliminates the need for manual intervention in hazardous environments, improving overall safety for operators.

The Specifications of Pneumatic Gate Valve

| Specification | Details |

|---|---|

| Type | Pneumatic Gate Valve |

| Ball Material | Stainless Steel |

| Attachment Type | Flanged |

| Thread Standard | N/A |

| Thread Size | N/A |

| Body Material | Cast Construction, Stainless Steel |

| Safe for Use With | Various media, pressure, and temperature |

| Handle Type | Pneumatic actuation, manual option |

| Handle Material | N/A |

| Maximum Working Pressure psi | As per design and application |

| Maximum Working Pressure bar | As per design and application |

| Operating Pressure | Dependent on pneumatic system |

The Parameter of Pneumatic Gate Valve

- Heavy Duty Cast Construction: Ensures durability and longevity, suitable for demanding industrial applications.

- ASA Bolt Hole Pattern: Allows for easy and standardized installation, ensuring compatibility with various piping systems.

- Stainless Steel Construction: Provides resistance to corrosion and wear, enhancing the valve’s lifespan in harsh environments.

- Thick Beveled Edge Knife Plate: Enhances sealing performance and prevents leakage, ensuring reliable operation.

- Resilient Rubber Seats: Seals effectively against pressure and vacuum, reducing the risk of leaks and improving overall performance.

- Pneumatic or Manual Actuation: Offers flexibility in operation, allowing for both automated and manual control options.

- Oversized Air Cylinder for Pneumatic Units: Ensures sufficient force and smooth operation, enhancing the efficiency of pneumatic actuation systems.

The Operation Theory of Pneumatic Gate Valve

The operation of a pneumatic gate valve involves the use of compressed air to control the movement of the valve’s gate. When the pneumatic actuator receives a signal, it directs air into the actuator chamber, causing the piston to move, which, in turn, opens or closes the gate. This process enables precise and efficient control of fluid flow. In the case of balancing valve symbol, it ensures proper distribution of flow within a system, while Barton 200AS and ITT Barton 288C are examples of flow meters used for measuring fluid flow rates. These components work together to regulate and monitor fluid flow in various industrial applications.

The Parameters Table of Pneumatic Gate Valve

| Parameter | Material |

|---|---|

| Valve Type | Pneumatic Gate Valve |

| Body Material | Stainless Steel |

| Gate Material | Cast Steel |

| Seat Material | Resilient Rubber |

| Actuator Material | Aluminum Alloy |

| Cylinder Material | Stainless Steel |

| Stem Material | Stainless Steel |

| Gasket Material | Nitrile Rubber |

| Packing Material | PTFE (Teflon) |

| Bolts and Nuts Material | Stainless Steel |

| Bonnet Material | Stainless Steel |

| Handwheel Material | Aluminum Alloy or Stainless Steel (optional) |