Boiler Pressure Reducing Valve

The Application of Boiler Pressure Reducing Valve

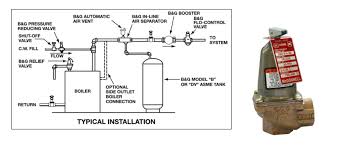

Introducing the Rotork Boiler Pressure Reducing Valve, a crucial component in boiler systems renowned for its precision and reliability. Functioning akin to a Watts 3/4 pressure reducing valve, it regulates and maintains optimal pressure levels within the boiler, ensuring efficient operation. Additionally, it serves as a 1 pressure relief valve, safeguarding against overpressure situations. With features akin to an air pressure valve, the Rotork Boiler Pressure Reducing Valve effectively controls pressure differentials, contributing to system safety and efficiency. Trust Rotork for innovative solutions in fluid control technology, with the Boiler Pressure Reducing Valve standing as a testament to their commitment to excellence.

What Is Boiler Pressure Reducing Valve?

A Boiler Pressure Reducing Valve is a device used to regulate and control the pressure of fluid entering a boiler, ensuring it remains within safe operating limits.

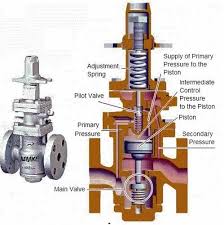

How Does Boiler Pressure Reducing Valve work?

The Boiler Pressure Reducing Valve works by reducing the pressure of fluid entering the boiler to maintain safe operating levels. It does this by automatically adjusting the valve opening based on the incoming pressure, ensuring that the pressure leaving the valve remains within the desired range.

Features of Boiler Pressure Reducing Valve

- Pressure Regulation: Boiler Pressure Reducing Valves effectively regulate and control fluid pressure entering the boiler, ensuring it remains within safe operating limits.

- Automatic Adjustment: They feature automatic adjustment mechanisms that respond to changes in incoming pressure, maintaining consistent pressure output.

- Versatility: These valves are versatile and can be used in various boiler systems, including residential, commercial, and industrial applications.

- Durability: Constructed from high-quality materials, Boiler Pressure Reducing Valves exhibit durability and reliability in demanding environments.

- Safety: They contribute to system safety by preventing overpressurization, which could lead to equipment damage or accidents.

- Efficient Operation: These valves facilitate efficient boiler operation by ensuring optimal pressure levels, which can help improve energy efficiency and reduce fuel consumption.

- Easy Installation: They are designed for easy installation and integration into existing boiler systems, minimizing downtime and installation costs.

Advantages of Boiler Pressure Reducing Valve

- Pressure Control: Boiler Pressure Reducing Valves effectively control and regulate the pressure of fluid entering the boiler, maintaining it within safe operating limits.

- Equipment Protection: They help protect boiler components and equipment from damage by preventing overpressurization.

- System Safety: These valves contribute to overall system safety by ensuring pressure levels remain within specified parameters, reducing the risk of accidents.

- Energy Efficiency: By maintaining optimal pressure levels, Boiler Pressure Reducing Valves can improve the energy efficiency of boiler systems, leading to reduced energy consumption and operational costs.

- Versatility: They are versatile and suitable for various boiler applications, including residential, commercial, and industrial settings.

- Durability: Constructed from high-quality materials, these valves offer durability and reliability in demanding environments.

- Easy Installation: They are designed for easy installation and integration into existing boiler systems, minimizing installation time and costs.

The Specifications of Boiler Pressure Reducing Valve

| Specification | Details |

|---|---|

| Type | Boiler Pressure Reducing Valve |

| Ball Material | N/A |

| Attachment Type | Threaded |

| Thread Standard | ANSI/ASME B1.20.1 |

| Thread Size | Various sizes available |

| Body Material | Brass or Stainless Steel |

| Safe for Use With | Water, steam, and other fluids |

| Handle Type | Lever |

| Handle Material | Stainless Steel or Plastic |

| Maximum Working Pressure | 150 psi |

| Maximum Working Pressure | 10.34 bar |

| Operating Pressure | Dependent on system settings |

The Parameter of Boiler Pressure Reducing Valve

- Type: Boiler Pressure Reducing Valve

- Ball Material: N/A

- Attachment Type: Threaded

- Thread Standard: ANSI/ASME B1.20.1

- Thread Size: Various sizes available

- Body Material: Brass or Stainless Steel

- Safe for Use With: Water, steam, and other fluids

- Handle Type: Lever

- Handle Material: Stainless Steel or Plastic

- Maximum Working Pressure: 150 psi (10.34 bar)

- Operating Pressure: Dependent on system settings

The Operation Theory of Boiler Pressure Reducing Valve

The operation theory of a Boiler Pressure Reducing Valve involves regulating fluid pressure entering the boiler. Similar to a brake pressure modulator valve and high-pressure relief valve, it reduces incoming pressure to maintain safe operating levels. This is achieved by adjusting the valve opening based on incoming pressure, ensuring that the pressure leaving the valve remains within the desired range for efficient and safe boiler operation.

The Parameters Table of Boiler Pressure Reducing Valve

| Parameter | Details |

|---|---|

| Type | Boiler Pressure Reducing Valve |

| Ball Material | N/A |

| Attachment Type | Threaded |

| Thread Standard | ANSI/ASME B1.20.1 |

| Thread Size | Various sizes available |

| Body Material | Brass or Stainless Steel |

| Seal Material | Rubber or Silicone |

| Spring Material | Stainless Steel |

| Safe for Use With | Water, steam, and other fluids |

| Handle Type | Lever |

| Handle Material | Stainless Steel or Plastic |

| Maximum Working Pressure | 150 psi (10.34 bar) |

| Operating Pressure | Dependent on system settings |