Butterfly Valve vs Gate Valve – Difference Between Gate Valve and Butterfly Valve | ZECOvalves in oil and gas

high performance butterfly valves

lug butterfly valve

lug style butterfly valve

Gate valves and butterfly valves are two very common valves. The two differ greatly in their respective structures, methods of use, and adaptation to the working environment. This article will help users better understand the difference between gate valves and butterfly valves, so as to better help users choose valves.

Table of Contents

- What is a Gate Valve?

- How does a Gate Valve work?

- Types of Gate Valve

- What is a Butterfly Valve?

- How does a Butterfly Valve work?

- Types of Butterfly Valve

- Butterfly Valve vs Gate valve

- 1. Structural Design

- Gate Valves

- Butterfly Valves

- 2. Working Mechanism

- Gate Valves

- Butterfly Valves

- 3. Applications

- What is the Purpose of a Gate Valve?

- What is the Purpose of a Butterfly Valve?

- 4. Price

- 5. Athletic Ability

- 1. Structural Design

- Advantages and Disadvantages – Difference Between Gate Valve and Butterfly Valve

- What are the Advantages of Gate Valves?

- What are the disadvantages of Gate Valves?

- What are the Advantages of Butterfly Valves?

- What are the disadvantages of Butterfly Valves?

- Which is better Butterfly Valve or Gate valve?

Before explaining the difference between gate valves and butterfly valves, let’s take a look at their respective definitions. Perhaps from the definition, you can carefully find the difference between the two.

What is a Gate Valve?

Gate valves, also known as sluice valves, cut off a medium in a pipeline by lifting a rectangular or round “gate” from the medium’s path. The direction of the gate’s movement is perpendicular to that of the medium’s flow.

Gate valves are cut-off valves that are only used when minimum restrictions and uniform linear flows are desired. They can either be completely open or completely closed which does not allow the adjustment of the medium flow. The medium discharge is normally complete and no residues are left in the pipes.

How does a Gate Valve work?

A gate valve is named after its disc, which behaves like a gate by either stopping or allowing media flow. It has a simple operation compared to other control valves, which makes it one of the most commonly used valves. Because a gate valve is a full-port valve, which means that the valve’s ports are the same size as the inner diameter of the connecting pipes, there is very little resistance to liquid or gas media that flows directly through it. Therefore, the pressure drop through the valve is quite low.

Types of Gate Valve

The gate valve can be classified in three ways:

- Disk Designs

- Solid wedge gate valve

- Flexible wedge gate valve

- Split wedge or Parallel disks gate valve.

2. Body Bonnet Joint Designs

- Screwed Bonnet,

- Bolted-Bonnet,

- Welded-Bonnet,

- Pressure-Seal Bonnet.

3. Stem Movement Designs

- Rising Stem Gate Valve or OS & Y Gate Valve,

- Non Rising Stem Gate Valve.

What is a Butterfly Valve?

Butterfly valves are also known as flap valves. They are composed of a fixed disc on the valve’s stem for closing and opening the valve. This disc rotates around the valve’s stem to regulate the flow of the medium in the pipeline. The direction of the disc’s movement is in place rotation only and requires a 90° rotation to fully open or fully close the valve.

Butterfly valves can either be used for regulating or isolating fluid flows and can control the flow easily. However, they leave residual materials in the pipeline.

How does a Butterfly Valve work?

The essential operation of a butterfly valve is achieved by turning its handle 90° or using a pneumatic or electric actuator. This turns the valve’s stem, which rotates the disc. In the fully closed position, the disc is perpendicular to the flow, and in the fully open position, the disc is parallel to the flow. Partial opening or closing of the disc can achieve proportional or throttled flow rates. In cases of a large butterfly valve or a valve used in a liquid application for which fast closure could produce a water hammer, a butterfly valve can be gear operated via a gearbox. The gearbox’s handwheel must be turned more than 90°, though, which eliminates the butterfly valve’s relatively fast closing speed. For a more comprehensive understanding, read our article on butterfly valves.

Types of Butterfly Valve

Butterfly valves come in a variety of shapes and sizes, each suited to particular pressures and purposes. There are three types of disk offset designs for the butterfly valves:

- Zero offsets (concentric) butterfly valve,

- Double offset (double eccentric) butterfly valve,

- Triple offset (triple eccentric) butterfly valve.

Butterfly Valve vs Gate valve

After the general definitions of gate and butterfly valves, you may have already noticed the differences between the two. Most especially their design, how they work, and their recommended applications. Let us discuss these further by tackling their differences one by one.

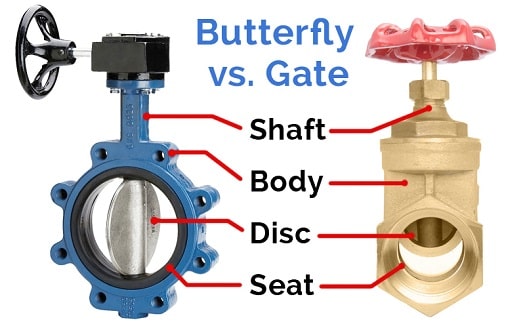

1. Structural Design

Gate Valves

As the name implies, the main function of a valve is as a gatekeeper. The gate is the main part of gate valves. A movable gate within the valve allows flow or blocks it. This movable gate is controlled by a mechanical assist such as a screw or lever, which lifts or lowers the gate within.

Gate valves come in many shapes and sizes but tend to be large. Think of the valves controlling the flow of water in the main water supply pipes. In spite of their sometimes prodigious size, gate valves are designed to be controlled by a single individual.

Butterfly Valves

A close cousin of the gate valve, and an ingenious variation, a butterfly valve can also come in many shapes and sizes. Such a valve also functions by using an internal gate. The difference between this and a gate valve is in the way the gate operates within the valve.

Unlike the gate valve, the gate within the butterfly valve remains fixed and swivels around an internal axis. The shape of the internal gate swiveling is the origin of the butterfly’s name.

The butterfly valve has the same function as the gate valve, which is allowing and blocking the flow. There are, however, some advantages and disadvantages to both types of valves, and it’s important to keep that in mind when choosing either valve.

2. Working Mechanism

Gate Valves

Gate valves use a movable door or gate to open and close the valve. This gate is lowered or raised using a mechanically assisted operator which is normally a threaded screw. Since gate valves can either be in the fully open or fully closed state, the resistance of the fluid flow when the valve is fully opened is smaller. This is because when the gate valve is fully open, the gate is entirely out of the medium’s path, providing an unobstructed flow.

In general, gate valves act as restrictions to the medium flow and they change the medium’s speed rather than its rate of flow. Moreover, the closing and opening speed of the gate valve is slow due to its high opening height.

Butterfly Valves

Butterfly valves belong to the category of quarter-turn valves and they consist of a rotating disc to regulate the medium flow. The disc is held at the center of the valve’s body by a stem. Unlike gate valves, butterfly valves have a short operation time since the operator is only rotated at 90° to allow or prevent fluid flow in the passageway.

A butterfly valve is usually operated using an actuator that turns the valve’s disc either parallel or perpendicular to the flow. The disc is parallel to the flow when the valve is in the fully open state and is perpendicular to it otherwise. In addition, the butterfly valve’s thickness creates resistance which obstructs the medium flow and causes the pressure to drop even if the valve is fully open.

3. Applications

What is the Purpose of a Gate Valve?

Gate valves have good sealing performances so they are often used for pipelines requiring strict sealing but do not need frequent switching. They can only be used in the fully open or fully closed state and not for regulating or throttling the medium flow rate because accurate control cannot be achieved.

If the valve is kept in the partially or intermediate open state, the valve’s seat and the gate will erode badly in just a short time. The chattering wedge will also tend to cause noises and vibrations in the pipeline.

Moreover, because the speed of the gate valve’s opening and closing operation is slow, they are not ideal for pipelines that require emergency shutoffs. But when pressure along the pipe is considered, gate valves can withstand higher pressures compared to butterfly valves.

Lastly, gate valves are widely used in large piping systems requiring uninterrupted bi-directional liquid and gas flows or in time-based uni-directional media discharges.

What is the Purpose of a Butterfly Valve?

Industrial butterfly valves are lighter compared to gate valves and thus are more convenient to operate and install for applications dealing with large pipe diameters. They are ideal for installations with limited space in which wafer butterfly valve types are recommended. In fact, butterfly valves are comparatively more extensively used in large sizes compared to gate valves.

Because butterfly valves open and close quickly and can be frequently operated, they are ideal for applications that require quick opening and closing, especially for emergency shutoffs. And aside from truncation purposes, they are also used to adjust or throttle flow rates. For pipelines containing small impurity particles, it is recommended to use butterfly valves.

Moreover, butterfly valves are termed high-performance valves because of their suitability in applications under moderate to high temperature and pressure conditions.

4. Price

Under normal conditions in the same specifications, diameter, and material, butterfly valves are more affordable compared to gate valves. Gate valves may have lower prices than butterfly valves in smaller sizes but their price also rapidly increases with the increase in caliber diameter. So in larger sizes, butterfly valves are still cheaper which makes them more extensively used in various industries.

5. Athletic Ability

In the above definition, we understand the difference between gate valves and butterfly valves in the direction of movement and the way of movement. In addition, since the gate valve can only be fully opened and fully closed, in the fully open state, the flow resistance of the gate valve is small; in the fully open state, the thickness of the butterfly valve produces resistance to the flowing medium. In addition, the opening height of the gate valve is high, so the opening and closing speeds are slow; while the butterfly valve can be opened and closed only by rotating 90°, so the opening and closing speeds are fast.

Advantages and Disadvantages – Difference Between Gate Valve and Butterfly Valve

After discussing the differences between gate valves and butterfly valves, below are the compiled advantages and disadvantages of each valve type.

What are the Advantages of Gate Valves?

- They can provide an unobstructed flow in the fully open position so pressure loss is minimal.

- They are bi-directional and allow uniform linear flows.

- No residues are left in the pipes.

- Gate valves can withstand higher pressures compared to butterfly valves

- It prevents water hammering because the wedge has a slow operation.

What are the disadvantages of Gate Valves?

- Can only be completely open or completely closed with no allowed adjustments for the medium flow.

- The operation speed is slow due to the gate valve’s high opening height.

- The valve’s seat and the gate will erode badly when kept in a partially open state.

- More expensive compared to butterfly valves especially in large sizes.

- They occupy a larger space for installation and operation compared to butterfly valves.

What are the Advantages of Butterfly Valves?

- Can be used for throttling fluid flows and can control the flow easily.

- Suitable for applications under moderate to high temperature and pressure conditions.

- Lightweight and compact design requires less space for installation.

- Fast operation time which is ideal for emergency shut-offs.

- More affordable in large sizes.

What are the disadvantages of Butterfly Valves?

- They leave residual materials in the pipeline.

- The thickness of the valve’s body creates resistance which obstructs the medium flow and causes the pressure to drop even if the valve is fully open.

- The movement of the disc is unguided so it is affected by the flow turbulence.

- Thick liquids can prevent the movement of the disc as it is always along the flow path.

- Possibility of water hammers.

Which is better Butterfly Valve or Gate valve?

For large water pipeline applications, butterfly valves are generally the best choice. Butterfly valves provide excellent leak tightness, are lightweight (compared to gates), are usually less expensive, and can be used to control flow up to a point. The main disadvantage (and it can be unacceptable) is pressure drop. Also, depending on flow rates, internal valve wear may be a problem since the disc, shaft, etc are directly in the flow. This will result in limiting flow rates as well as limiting throttling capability.

Another big advantage of a butterfly valve over a gate valve is the time required to close the valve in the event of an emergency. A large gate valve takes a lot of effort and time to close while a butterfly valve can be closed much more quickly either by hand or any kind of fast-acting linear actuator as it only has to be turned 90 degrees between wide open and completely closed.

Gate valves are much more suited for use as isolation valves so the system can be drained for repairs. Gate valves must also be mounted so the gate moves vertically up when opened and down when closed. Mounting the valve in any other position, especially upside down, is virtually guaranteed that dirt, rust, and debris will collect between the valve casing and the gate disc while open, jamming the gate and making it impossible to close the valve without causing major damage to the valve and its actuator if controlled remotely. Whereas butterfly valves can be mounted in any orientation including upside down.

The best course of action at this stage is to contact different valve suppliers with your specifications and see what can be supplied. Make your choice accordingly.

We are gate & butterfly valve suppliers. Please feel free to contact us if you are interested in our products.

Related Tags :

ZECO Valve

NBR Butterfly Valve

Gate Valve Repair

What is a Globe Valve?

Gate Valve vs Ball Valve

What is an Axial Check Valve

Manual Operate Gate Valve Manufacturer

What are Globe Valves?

Ten articles before and after

Use, Installation, and Maintenance Of The Ball Valve

How To Maintain Butterfly Valve

The Function Of a Check Valve

What Is a Check Valve?

Gate Valve vs Globe Valve

The Differences Between Ball Valves And Butterfly Valves

Can a Ball Valve Be Used As a Control Valve?

Butterfly Valve Introduction Guide

Ball Valves

Ball Valve vs Gate Valve