furuno speedlog gate valve

The Application of Stainless Steel Check Valve

Renowned for its commitment to quality and innovation, Cameron offers a comprehensive range of stainless steel check valve solutions to meet the demands of diverse industries. From the dependable stainless steel swing check valve to the versatile stainless steel ball check valve, Cameron’s portfolio delivers exceptional performance and reliability. Engineered to withstand harsh environments, these stainless steel check valves are the preferred choice for critical applications where corrosion resistance and long-lasting service are paramount. Backed by Cameron’s engineering expertise, these check valve solutions seamlessly integrate with process systems, ensuring efficient one-way flow control and enhanced system integrity.

What Are The Types Of Stainless Steel Check Valve?

- Swing Check Valve:

- The swing check valve features a hinged disc that swings open to allow flow in one direction and closes to prevent backflow.

- Stainless steel construction provides excellent corrosion resistance.

- Commonly used in pipelines, pumping systems, and industrial processes.

- Ball Check Valve:

- The ball check valve uses a spherical ball that seals against a valve seat to allow flow in one direction.

- Stainless steel ball and body offer durable performance in harsh environments.

- Frequently found in chemical processing, oil and gas, and power generation applications.

- Lift Check Valve:

- The lift check valve has a guided disc that lifts off the valve seat to permit flow in one direction.

- Stainless steel construction ensures long service life and compatibility with corrosive media.

- Widely used in process piping, HVAC systems, and plumbing applications.

- Wafer Check Valve:

- The wafer check valve is a compact design that fits between pipe flanges.

- Stainless steel components provide strength and corrosion resistance.

- Common in water, steam, and air distribution systems.

What Is Stainless Steel Check Valve?

A stainless steel check valve is a type of valve that allows fluid to flow in one direction while preventing backflow. Constructed with high-quality stainless steel materials, these valves are designed to withstand harsh environments, corrosive media, and high-pressure applications. The stainless steel construction provides superior strength, durability, and resistance to corrosion, making these valves ideal for use in industries such as oil and gas, chemical processing, power generation, and water treatment. Stainless steel check valves are available in various designs, including swing check, ball check, and lift check, to suit the specific requirements of the application. Their reliable operation and long service life make them an essential component in many industrial and commercial piping systems.

How to Select the Right Stainless Steel Check Valve?

When selecting the right stainless steel check valve for an application, several key factors should be considered. These include the fluid type, pressure and temperature requirements, flow rate, pipe size, and the installation orientation. Additionally, the valve material and design (such as swing check, ball check, or lift check) must be compatible with the system specifications. Carefully evaluating these parameters will ensure the stainless steel check valve chosen provides the necessary performance, durability, and reliability for the specific application, while also meeting any relevant industry standards or regulations. Consulting with a valve expert can also help identify the most suitable stainless steel check valve solution for the job at hand.

Features of Stainless Steel Check Valve

Corrosion Resistance:

Stainless steel check valves are highly resistant to corrosion, making them suitable for use in aggressive environments or with corrosive fluids.

Durability:

The robust stainless steel construction provides exceptional strength and resilience, ensuring long-lasting performance and minimal maintenance requirements.

High-Temperature Capability:

Stainless steel check valves can withstand elevated temperatures, making them suitable for a wide range of industrial and commercial applications.

Compact Design:

Many stainless steel check valve models feature a compact, space-saving design that simplifies installation and integration into piping systems.

Reliable Operation:

The precision engineering and tight tolerances of stainless steel check valves ensure reliable, consistent, and efficient one-way flow control.

Versatility:

Stainless steel check valves are available in a variety of designs, such as swing check, ball check, and lift check, to accommodate diverse application requirements.

Ease of Maintenance:

The durable construction and simple design of stainless steel check valves often allows for easy inspection, servicing, and replacement when necessary.

Advantages and Disadvantages of Stainless Steel Check Valve

Advantages of Stainless Steel Check Valves:

Corrosion Resistance:

Stainless steel construction provides excellent resistance to corrosion, making these valves suitable for use in harsh, corrosive environments.

Durability:

The robust, high-quality materials used in stainless steel check valves ensure long service life and minimal maintenance requirements.

Temperature Tolerance:

Stainless steel check valves can withstand a wide range of temperatures, from cryogenic to high-heat applications.

Hygienic Design:

The smooth, non-porous surfaces of stainless steel check valves make them easy to clean and maintain, making them suitable for sanitary applications.

Versatility:

Stainless steel check valves are available in various designs, such as swing, ball, and lift, to accommodate diverse flow control requirements.

Disadvantages of Stainless Steel Check Valves:

Higher Cost:

Stainless steel is generally more expensive compared to other valve materials, which can increase the initial investment.

Potential for Galvanic Corrosion:

When used in systems with dissimilar metals, stainless steel check valves may be susceptible to galvanic corrosion, requiring careful consideration of material compatibility.

Potential for Scaling:

Depending on the fluid media, stainless steel check valves may be prone to scaling, which can impact their performance and require more frequent maintenance.

Limited Elasticity:

The rigidity of stainless steel components may limit the valve’s ability to accommodate thermal expansion or system vibrations, which can potentially lead to leaks or premature failure.

The Specifications of Stainless Steel Check Valve

| Specification | Details |

|---|---|

| Type | Stainless Steel Ball Check Valve |

| Ball Material | 316 Stainless Steel |

| Attachment Type | Threaded |

| Thread Standard | NPT |

| Thread Size | 1/2 inch |

| Body Material | 316 Stainless Steel |

| Safe for Use With | Corrosive Fluids, Chemicals, Water, Oil, Air, Gas |

| Handle Type | Handwheel |

| Handle Material | 316 Stainless Steel |

| Maximum Working Pressure | 800 psi (55 bar) |

| Operating Pressure | 0-800 psi (0-55 bar) |

The Installation Steps for Stainless Steel Check Valve

Step 1: Inspect and Prepare the Valve

- Carefully unpack the stainless steel check valve and inspect it for any damage or defects.

- Ensure that the valve’s size, material, and pressure rating are appropriate for the application.

Step 2: Prepare the Pipe System

- Shut off the flow of fluid and depressurize the pipeline where the check valve will be installed.

- Cut the pipe to the required length and ensure the ends are clean, burr-free, and properly aligned.

Step 3: Install the Check Valve

- Apply a suitable thread sealant or gasket to the valve’s threads or flanges.

- Position the check valve in the desired orientation, ensuring the flow direction arrow matches the intended flow.

- Tighten the valve connections securely using the appropriate tools.

Step 4: Leak Test the Installation

- Slowly restore pressure to the pipeline and check for any leaks around the valve connections.

- If any leaks are detected, depressurize the system and tighten the connections further.

Step 5: Commissioning and Monitoring

- Once the installation is confirmed to be leak-free, slowly open any upstream and downstream valves to allow the system to pressurize.

- Monitor the check valve’s operation and performance during the initial startup and over time to ensure continued reliable performance.

The Operation Theory of Stainless Steel Check Valve

Operation Theory of Stainless Steel Check Valves

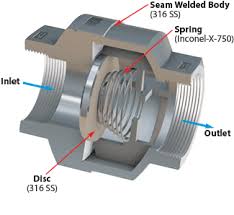

Stainless steel check valves operate based on the principle of one-way fluid flow control. The key components that enable this functionality are:

- Valve Body: The stainless steel body provides a durable and corrosion-resistant housing for the internal valve mechanism.

- Valve Disc/Ball: This movable component is typically made of stainless steel and is designed to open and close the valve port based on the direction of fluid flow.

- Spring: A spring is often incorporated to apply a closing force on the valve disc/ball, ensuring tight sealing when there is no forward flow.

During normal forward flow, the pressure differential across the check valve pushes the disc/ball open, allowing the fluid to pass through. When the flow reverses direction, the disc/ball is forced back onto the valve seat, creating a tight seal and preventing backflow.

Precision Pneumatic Control Valves

Precision pneumatic control valves, often used in conjunction with stainless steel check valves, employ advanced pneumatic actuators to provide precise, reliable, and repeatable control of fluid flow. These control valves utilize pressurized air or gas to position a valve plug or ball, enabling accurate regulation of flow rate, pressure, and other process parameters.

Chemical Industry Pneumatic Actuators

In the chemical industry, pneumatic actuators are widely used to operate control valves, including stainless steel check valves. These actuators leverage compressed air or gas to provide the mechanical force required to open and close the valve. Chemical industry-specific actuators are designed to withstand exposure to corrosive substances and operate reliably in demanding process environments.

The combination of stainless steel check valves, precision pneumatic control valves, and chemical industry-rated pneumatic actuators enables the effective management of fluid flow, pressure, and other critical parameters in various industrial applications, particularly those involving harsh or corrosive media.